Where is the Journey Headed? The Future of High-Power Semiconductors

This article discusses the future of high-power semiconductors in power electronics systems technology of energy savings, dynamics and noise reduction.

Power modules have proven to be the driving force behind the rapid development in the area of power electronic systems technology, particularly in terms of energy savings, control dynamics, noise reduction as well as weight and volume reduction. Power semiconductors are primarily used to control the energy flow between energy generation and consumption. This is done extraordinary precisely and with exceptionally low losses.

The ongoing technological progress in power electronics for industrial applications is primarily driven by five aspects, energy efficiency, operating temperature, miniaturization, reliability and cost reduction, which also influence each other to an extent. The trends briefly outlined have continued to drive the development of power semiconductors in the last thirty years and will also do so in the future.

Figure 1: The development of power density over a thirty-year period – and no end in sight

From an initial value of 30kW/cm², power densities of 110kW/cm² are possible today, thanks to innovative assembly and interconnection techniques. It is generally assumed that the semiconductor industry will achieve significantly higher values yet with IGBT modules owing to new developments. It is also clear that further power increases will require new housings.

In parallel, the evolution in the area of converters has also continued. This is accompanied by the development of chip technology and housing design. The new concepts associated with this, such as parts commonality concepts across voltage classes, require innovative solution approaches on the part of the semiconductor manufacturers in order to meet the future requirements of modern, energy-efficient power electronics.

High-power IGBT modules are used in various applications, such as industrial drives, transportation and wind turbines. Compact design, energy efficiency and reliability are the key elements in these applications. It is foreseeable that new applications in even more demanding environments will introduce different and probably more stringent requirements with respect to the durability and resilience of both, converters and module technology. All of this leads to the question how solutions will be shaped in the future to meet the different requirements.

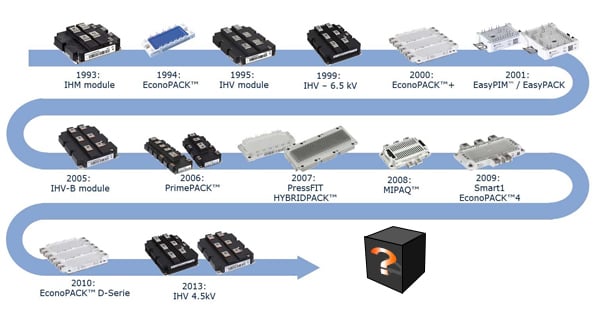

Figure 2: Infineon has set global industrial standards in the past with innovative modules

Drives

In addition to power generation from renewable energies, the use of fossil fuels continues to represent the lion’s share in terms of power supply. It is expected, that the world’s population will grow by 1.7 billion to 8.2 billion between 2005 and 2030 (1). Added to this is an unrelenting trend toward urbanization. This development requires significant investment in the extraction and distribution of energy sources such as oil and gas. New production techniques are allowing new resources to be exploited. High-efficiency pump drives are needed here, at the core of which are the IGBT modules. In the case of industrial drives, more and more unregulated drives are now replaced by variable speed drives to increase energy efficiency.

Converters in industrial applications like steelworks, oil and gas industry or mining enterprises are often exposed to extremely harsh conditions. Glowing steel, hazardous atmosphere, variable operating modes and periodic overloads mean high electrical and mechanical stress, which in turn requires extremely stable constructions. Rolling mill drives ranging from some 100 KW up to double-digit MW values are used in low and medium voltage applications both in new developments and for modernizing and retrofitting existing plants. Robust and durable power electronic concepts are mandatory to fulfill these requirements.

Traction

The traction market is heavily depending on infrastructure projects, which are instituted by the individual states and countries as well as by cities and municipalities. Rail transportation is experiencing a renaissance around the globe. Numerous new transport companies are emerging worldwide as part of large mergers as this is the only way to manage the expected traffic volume. The number of new construction and expansion projects is growing continuously. Rail-based local area transportation systems are constructed in many cities, in some even for the first time. Ambitious new rail construction projects are implemented in several emerging economies with high economic growth rates both in the area of freight and high-speed passenger services (2).

Two developments can be identified globally as the driving force behind the traction market: Urbanization and increasing mobility. Even if the individual projects were planned and financed years in advance, there is still a demand to use the latest technologies. This ensures that the requirements in relation to cost and in particular time savings are fulfilled. As with drive converters, compact design and weight reduction are key factors within rail components too.

Wind energy

As the portion of renewable energies in power generation continues to grow steadily, this is leading to an increased need for power semiconductors. On-shore wind turbines are one of the most economical sources of renewable energy at present. Complex frequency converter systems are an important component of the plants as they enable grid compatible supply of the electricity generated in the first place. Modern offshore wind turbines can now deliver an output power of up to 7MW. The increasing power of the generators and the space restrictions in these applications demand compact and powerful converter concepts. Low maintenance and lifecycle costs play a significant role when considering the cost-efficiency of such projects. The platform approach based on converter concepts is therefore taken into account with design efficiency being enabled in every respect.

Power electronic solutions have to be highly robust and durable to meet the substantial demands of applications such as those just outlined in the area of wind power but also for drive systems for traction, medium-voltage industrial drives or high-voltage DC transmission systems. Electrical energy can be transported over long distances in an extremely cost-efficient manner with the aid of high-voltage DC transmission technology. The connection of offshore wind farms to the on-shore power supply grid is a possible application in this respect.

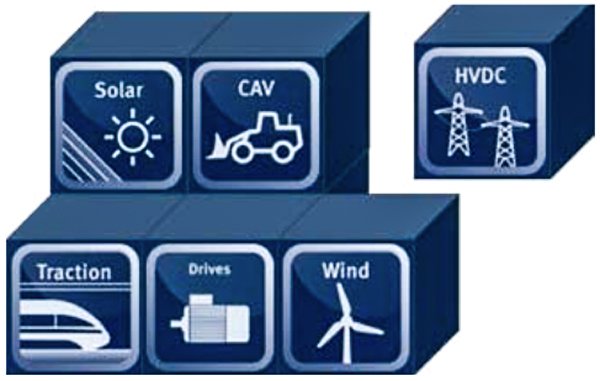

Figure 3: The applications' diversity and different requirements have to be taken into account by a new module standard

“The Answer”

The new challenges IGBT technology faces are growing primarily as a result of increased demands from the applications. Looking at the successful developments of power semiconductors in recent years, it is obvious that these were enabled on the basis of chip technologies. The focus was mainly on the latest chip generations without modifying the package technology. The new IGBT chips have been predominantly integrated into existing packages – an approach that at some point will reach its limits. As system requirements continue to grow and new chip generations come on stream, it is essential that new packages are developed with corresponding capabilities. Nothing less than “The Answer” is needed to meet these challenges.

Infineon will deliver this answer – as already done in the past – with a new module standard for high-power IGBTs. This new standard high-power platform was hinted for the first time at PCIM 2014 as “The Answer”. One of the major driving forces in the company in searching for and implementing of new technologies was the fundamental understanding of the customer’s needs and an associating system approach. The technical detail fulfilling the requirements of the different applications and application scenarios, such as high-power density, efficiency, long lifecycle, and robustness are implemented in a new module platform called “The Answer”. Infineon’s new housing standard for high-power IGBT modules covers several voltage classes from 1200V to 6.5kV. The scalability of the new standard housing

will simplify the system design considerably. Moreover, the robust architecture offers long-term reliability even in the case of applications exposed to the harshest environmental conditions.

Figure 4: Defining a new industrial standard, the high-power platform "The Answer" for several voltage classes from 1200V up to 6.5kV, among others with 400A for 4.5kV and 275A for 6.5kV, and a dimension of 100mm x 140mm x 40mm

Modern converter concepts demand high energy efficiency and flexibility in the process of design and construction. The converter dimensions can be optimally adapted to the respective power requirement of the drive on the basis of the new scalable high-power platform.

The package allows a previously developed converter to be easily extended by adding further modules. The future availability of the package for the voltage classes common today allows interchanging the different voltage classes based on the original design of the converter. The flexible concept of the new platform allows the connection of similar parts in parallel, thus enabling a simplified structure to be used for the connection between the DC link terminal and capacitors. Additionally, the AC terminals can be connected in parallel with only one busbar.

This shortens development times and reduces system costs. The new platform supports the time-to-market requirement and competitiveness utilizing the latest technology, both in terms of system costs and the future-poofing of the design.

About the Author

Hubert Kerstin works as the Marketing Director at Infineon Technologies AG, a German semiconductor manufacturer founded in 1999 that markets semiconductors and systems for automotive, industrial, and multimarket sectors, as well as chip card and security products.

Björn Rentemeister worked as a Manager Product Marketing for High Power High Voltage IGBT Module at Infineon Technologies, a world leader in semiconductor solutions that make life easier, safer and greener.

Thomas Risse worked as the Technical Performance and Investment Controller at Infineon Technologies where he is responsible for Investment controlling, planning, management and control of all operational investments, he was also involved in technical performance controlling and further development of existing processes and tools of the company. He holds a Bachelor's Degree and Master's Degree in Economics both earned at the University of Applied Sciences South Westphalia.

References

- United Nations, Department of Economic and Social Affairs, Population Division (2006). World Urbanization Prospects: The 2005 Revision. Working Paper No. ESA/P/WP/200.

- Study by VDE “Energieoptimaler Bahnverkehr“