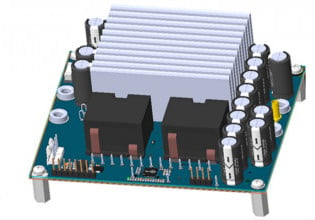

Latest Generation IGBT Modules for Efficient, Reliable & Power Dense Systems

This article discusses Dynex' new generation of high-power IGBT modules, covering a 3.3kV to 6.5kV voltage range.

The ever-changing landscape of the power electronics market is increasing the need for efficient, reliable and power-dense systems across industries. The demand for such systems is encouraging designers worldwide to rapidly embrace new IGBT-based technologies. Dynex has responded to this industry-wide requirement with its new generation of high-power IGBT modules, covering a 3.3kV to 6.5kV voltage range.

Efficient Systems

A thorough understanding of the operating conditions of the end application is the key to developing highly targeted IGBT specifications. At Dynex, system-level optimization is central to the IGBT design process.

By offering up to three chips at every rated voltage and current level, Dynex is able provide solutions for every operating window (PDF) within the end application. This targeted approach for design and development has resulted in Dynex’s next generation IGBT modules providing high system-level efficiency. Simulation performed under typical operating conditions on the 3.3kV, 1500A module confirms the superior performance of Dynex modules: please refer to figures 1, 2 and 3. Similar results are observed with 4.5kV and 6.5kV modules.

Figure 1. 3-Phase 2-Level Topology @ 385A RMS Current

Figure 2. 3-Phase 2-Level Topology @ 385A RMS Current

Figure 3. 3-Phase, 2-Level Topology Operating @ 750Hz & 385A rms Current

Reliable Systems

The key reliability parameters from an IGBT module perspective include:

- Maximum operating junction temperature,

- IGBT SOA,

- Anti-parallel diode’s reverse bias safe operating area (RBSOA), and

- The ability to withstand high transient, i.e., high di/dt capability.

While the information regarding points 1, 2, and 3 are readily available in datasheets from all manufacturers, point 4 is given indirectly, as a recommended value at which the typical switching measurements are shown.

During switching of the IGBTs in half-bridges, faster turn on and turn off times result in lower switching losses; however there is a trade-off: faster turn on and turn off times result in abrupt disruptions of current flows (high di/dt) through the IGBT, which - when coupled with circuit inductance and the parasitic inductance of the modules themselves - will result in high transients (high dv/dt). These transients have a deteriorating effect on the modules and in some extreme cases result in immediate failures.

Often, the di/dt related failures are due to the non-uniform distribution of current flow in the antiparallel diodes. With a thorough understanding of this problem, the designers at Dynex made significant improvements to the uniformity of current distribution in the anti-parallel diodes. With the new generation IGBT modules, Dynex offers both a class-leading RBSOA and a 150°C operation for the trench gate modules.

About the Author

Siva Uppuluri is experienced applications engineer and product marketing manager with a demonstrated history of working in the semiconductor industry. He has Master's Degree focused in Electrical engineering and renewable energy systems from the University of Leeds, and Master of Business Administration from the University of Cambridge.

This article originally appeared in the Bodo’s Power Systems magazine.