ROHM Technology Ensures Electrode Height of Automotive MOSFETs After Mounting

ROHM announced the development of 1.6mm x 1.6mm MOSFETs that deliver superior mounting reliability. The RV4xxx series is AEC-Q101 qualified, ensuring automotive-grade reliability and performance under extreme conditions. ROHM's original package processing technology enables the miniaturization of automotive components, such as ADAS camera modules, that need high quality.

ROHM notes that in recent years, the growing number of vehicle safety and convenience systems such as ADAS cameras has highlighted the challenge of limited space to accommodate these systems, thereby spurring the demand for smaller components. To meet this demand, bottom-electrode type MOSFETs that can be miniaturized while maintaining high current are increasingly attracting attention.

However, for automotive applications, optical inspection is performed during the assembly process to ensure quality. In the case of bottom electrode components, solder height cannot be verified after mounting, making it difficult to confirm mounting conditions.

This time, ROHM utilizes the company's original Wettable Flank formation technology, resulting in a consistent solder quality. This consistent solder quality extends even to bottom electrode type products.

This technology allows automatic inspection machines to easily verify solder conditions after mounting.

Availability: Now (samples), September 2019 (OEM quantities)

Key Benefits

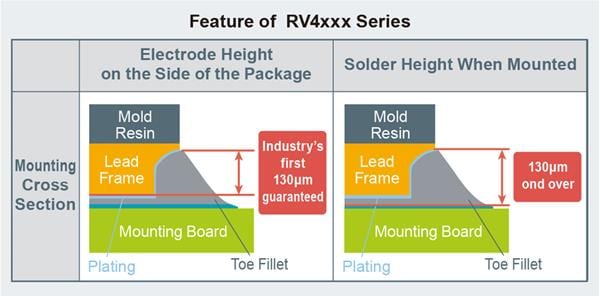

- Proprietary Wettable Flank technology guarantees an electrode height on the side of the package of 130μm

ROHM's Wettable Flank formation technology entails making a cut into the lead frame on the side of the package before plating. However, burrs can result from cutting into the lead frame more frequently as the height of the cut increases.

For this reason, ROHM developed a novel method that introduces a barrier layer on the entire surface of the lead frame to minimize burrs. This method not only prevents the component rise and solder defects during mounting, but ROHM says it is the first on the market to ensure a 130μm electrode height on the side of DFN1616 (1.6mm x1.6mm) packages.

- Compact bottom electrode MOSFETs reduce mounting area

Until recently, Schottky barrier diodes (SBDs) were often used in the reverse connection protection circuits of ADAS camera modules.

However, due to the larger currents required by high-resolution cameras in advanced vehicle systems, SBDs are increasingly being replaced by compact MOSFETs that provide low on-resistance and less heat generation.

For example, at a current and power consumption of 2.0A and 0.6W, respectively, conventional automotive MOSFETs can reduce mounting area by 30% compared to SBDs.

On the other hand, adopting bottom electrode MOSFETs that can deliver excellent heat dissipation while supporting large currents in an even smaller form factor makes it possible to decrease mounting area by as much as 78% compared to conventional SBDs. These MOSFETs can also decrease mounting area by as much as 68% compared with conventional MOSFETs.