Measuring High-Voltage Power Transistors with Oscilloscopes

Saelig Company, Inc. announces the availability of the CLIPPER CLP1500V15A1 - a new, high technology oscilloscope adapter that allows small voltages to be measured in the presence of very high voltages, such as those present on switching MOSFETs or IGBTs (Insulated Gate Bipolar Transistors). Making accurate measurements in the presence of very high voltages has previously been extremely challenging, but using the CLIPPER CLP1500V15A1, the VdsON or RdsON of a switching transistor can now be easily seen in high resolution (e.g. 100mV/div) on an ordinary digital oscilloscope. Determining the switching speeds, Safe Operating Area (SOA), and temperature effects of MOSFETs and IGBTs is now greatly simplified with the CLIPPER CLP1500V15A1.

The CLIPPER CLP1500V15A1 represents a leap forward in transistor switch testing, essential both in the design verification phase and production process monitoring. In typical use, the CLIPPER is connected between Drain and Source terminals of a Power MOSFET. The output signal provides a 1-to-1 picture of what is occurring across the MOSFET, without the disturbing influence of the high drain voltage. In this way, the oscilloscope resolution can be reduced to 0.2V per division, giving excellent visibility of the on-time switching characteristics.

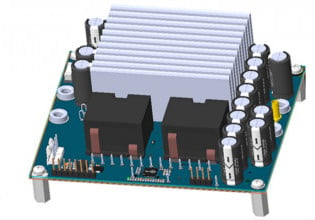

The popularity of IGBTs has soared in recent years due to an increase in high voltage, high power applications, at which they excel. IGBT modules have current ratings well into the 100s of amps, and they are well suited for high power applications such as PWM designs, electric vehicle and appliance motor drives, power factor correction converters, solar inverters, uninterruptable power supplies (UPS), inductive heating cookers, and high frequency welders.

The CLIPPER can directly measure the voltage between Drain and Source (Vds) of a power transistor (MOSFET or IGBT). The output voltage measurement is limited to a safe range between 0 and 2V (Lo Range) or 0 to 14V (Hi Range). This allows the oscilloscope to be set to the appropriate full-scale range, with a sensitivity of 200mV or 2V per division.

The high resolution Vds information obtained, can be used for indirect measurements such as: Measuring RdsON during operation (since switching current is usually known). Observing changes to the RdsON during operation, indicating thermal resistance changes (detecting insufficient heatsinking or cooling). Junction temperature - directly visualized based on RdsON. Thermal stability - directly visible as the load is dynamically varied. For thermal process monitoring, if the RdsON is not stable (i.e. a non-stable SOA), then a reliability issue exists. This could be a catastrophic thermal runaway issue, resulting in shutdown, or the presence of a higher than expected junction temperature (Tj), reducing the transistor lifetime.

In the verification phase of a product, design issues causing SOA problems can include: incorrect load regulation, incorrect transistor selection, gate drive optimization problems, IGBT turn-on issues, or poor thermal design. These issues and others caused by variations in production processes (e.g. soldering quality, PCB thermal and heatsink conductivity, or cooling problems) can all benefit from using the CLIPPER.

The CLIPPER is suited to: production screening, 100% product evaluation, electrical and thermal design verification and qualification, repair and maintenance. No calibration or external power is required for the CLIPPER CLP1500V15A1, which comes supplied in an attractive aluminum transport case, together with an assortment of SMA and BNC adapters.