Bourns Design Boosts High-Power Shunt Resistor Accuracy in Current Sensing

Bourns has added a third pin for supply ground and precision through-hole pin placement in its CSM2F Series, helping the accuracy of current measurement.

Accurately monitoring current is a critical function in many applications including battery management, motor control, and electric vehicle charging. One of the most common ways to monitor current is through a current sense resistor.

CSM2F Series power shut resistor with through-hole sensing pins. Image used courtesy of Bourns

Designed for high-power current sensing applications, Bourns has announced an extension to its CSM2F series of high-power shunt resistors. These models introduce new packaging options designed for higher accuracy to include through-hole metal sensing pins for more precise placement of resistor sensing points.

The new series also features an option for a third pin that directs current from the sensing circuit supply directly to the ground, eliminating errors through the ground side sensing point. As with prior surface-mount variants, electron beam welding technology enables the resistors to support high-power designs up to 50 watts while measuring currents in excess of 1,400 amperes.

Through-Hole Pin Placement Enhances Accuracy

Prior variants of CSM2F are offered in surface-mount (SMD) packaging to support rapid manufacturing. The new series is released with tin-plated copper through-hole pins, or bare copper depending on manufacturing and operating conditions. The new sensing pins are designed to allow more accurate placement of resistor voltage sensing points on the printed circuit board. While SMD can offer higher manufacturing throughputs, placing of the sensing pads can be less precise and introduce sensing errors.

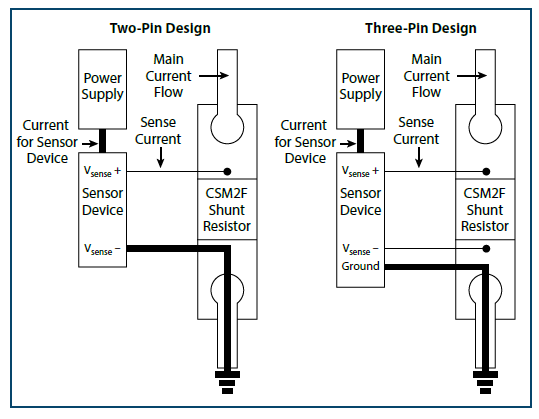

Figure 1. CSM2F SMD and through-hole mount packaging options. Image used courtesy of Bourns

Third Sensor Supply Ground Pin Removes Sensing Errors

The option for a third sensor supply ground allows current from the sensing circuit (op amp, diff amp, etc.) to move directly to the system ground, eliminating sensing errors that occur when this current is otherwise passed through the ground side sensing pin.

Figure 2. Third pin reduces errors from sensor circuit supply. Image used courtesy of Bourns

Sense Resistors Not Only Option for Measuring Current

Besides sense resistors, current can be sensed and measured in several other ways. Some of these include Hall Effect sensors, Rogowski coils, and transformers.

Compared with other options, sense resistor solutions are generally smaller and less expensive, with good linearity over the current measurement range. However, they do require placement within the signal path, and conditioning the resulting voltage signal for use within the larger system must be considered.

Table 1. Options for monitoring current. Image used courtesy of Bourns

Other CSM2F Series Extension Features

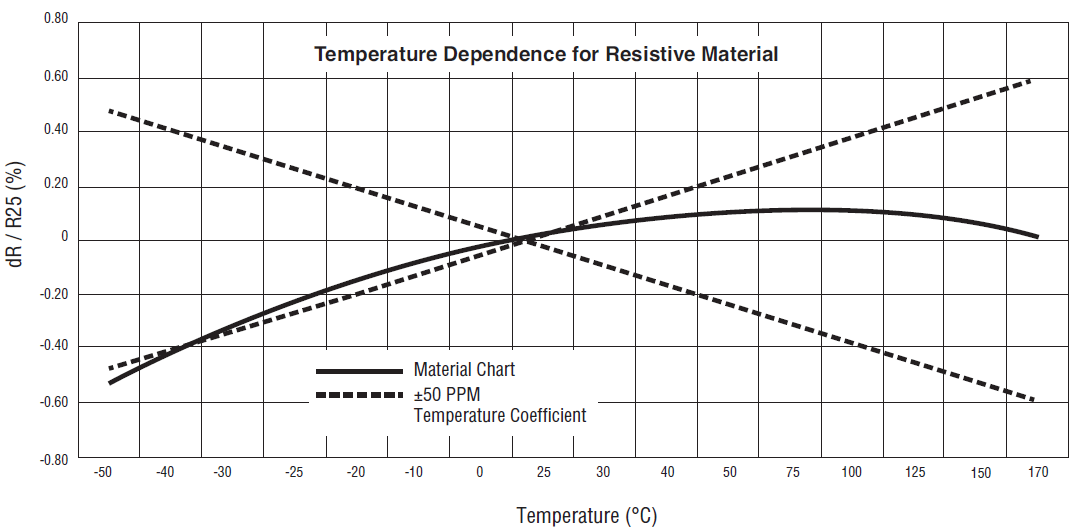

Along with packaging modifications for improved accuracy, the CSM2F series extension features a wide resistance range from 25µΩ to 200µΩ with a low TCR of +/-50 parts per million/degree Celsius, providing good linearity over temperatures up to 35 degrees C above room temperature (25 degrees C). Three different surface finishes are available based on environmental and soldering needs with four standard package sizes: 6918, 8518, 7036, and 8536. Construction with a metal alloy resistive element offers a thermal EMF as low as 0.25 µV/K. The components are ROHS- and AEC-Q200-compliant for automotive applications.

Figure 3. CSM2F-6918 resistance drift over temperature. Image used courtesy of Bourns

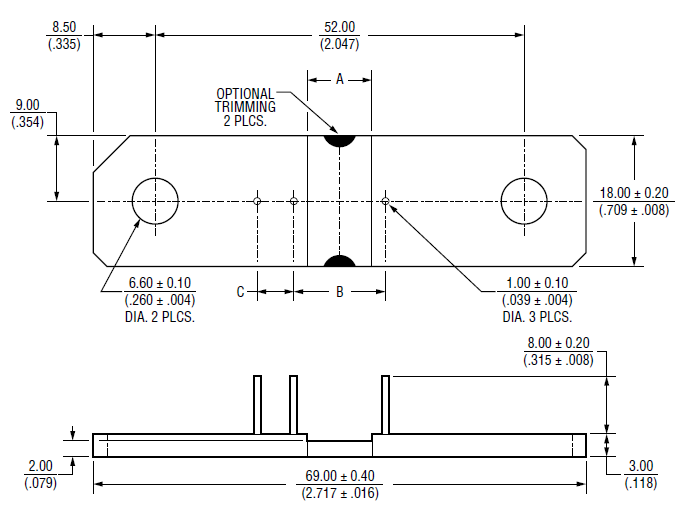

Figure 4. CSM2F-6918 product dimensions—millimeters/(inches). Image used courtesy of Bourns

Current Sensing Accuracy Critical for Rechargeable Batteries

Accurate battery current measurement is essential in automotive and other applications where rechargeable batteries are commonly used. In addition to overcurrent and overvoltage protection, monitoring the current is important for proper charge and discharge operations. Sub mΩ resistances can minimize the voltage drop across the sense resistor, helping to meet system design tolerances. High-power sense resistors like the CSM2F are well-suited to automotive applications where the currents of an engine starter can reach up to 1,000 A. Automotive applications will also value a low temperature coefficient of resistance (TCR) since they are subject to wide variations in ambient operating temperature.

Figure 5. Battery management current sense application. Image used courtesy of Bourns

Even Small Current Sensing Errors Impact Markets

Individual errors may seem small in applications such as current sensing, but combined, the impacts on the end system in terms of cost, performance, and reliability can be significant to discerning customers in competitive markets including automotive.