Understanding Phase Shift Correction in Power Analysis

Using shunts to measure currents in power analysis might be an option for small currents, but when you look at measuring currents above 50A then typically current sensors come into play.

Every current sensor in the world produces a gradually increasing phase error in the high-frequency region due to group delays of the circuitry. Additionally, differences in the design of various sensor models cause the magnitude of this error to vary.

A phase shift correction function allows to compensate this error. To make such a phase shift correction function work properly you need two things:

- A power analyzer making the correct calculations in its software

- A current sensor with a known phase shift

A good way to explain the calculations in the power analyzer software is by comparing it to the “deskew” function of an oscilloscope: If two different signals arrive at the oscilloscope at different times due to latencies then the “deskew” function lets you align those signals by compensating the latency with a fixed time value.

When you enter the phase shift correction value in a power analyzer like HIOKI’s PW6001 then you basically do the same thing because phase shift is essentially a time delay between current and voltage.

Figure 1: HIOKI PW6001 power analyzer

Figure 2: Time delay of HIOKI CT68 sensors

As an example, here is how this delay looks for a HIOKI CT68 series current sensor. The time delay is shown in nanoseconds against the frequency in figure 2. 100ns delay at 100Hz doesn’t have the same impact as 100ns delay at 1MHz. This becomes clear when translating the above time delay into phase delay values described in degrees (see figure 3).

Figure 3: Phase delay vs frequency

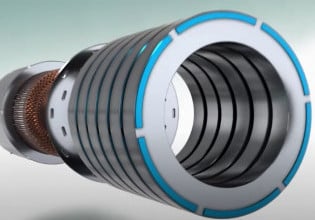

Figure 4: HIOKI current sensors

To make things as straight forward as above of course you need a current sensor where the time delay is the same regardless of the frequency. With HIOKI current sensors like the CT68 series this is the case so coming back to the deskew function you only need one value to compensate the phase shift of the sensor. This is one of the things that makes HIOKI sensors special – but it is not standard for current sensors currently on the market. Here is what would happen with a typical current sensor (see figure 5). A sensor where the time delay values are different depending on the frequency will make the phase shift compensation in a power analyzer much more difficult. Because which value do you use as your “deskew” parameter?

Another thing that makes HIOKI current sensors special is that for the phase delay it is not relevant where your wire core is located within the sensor when you make the measurement (see figure 6). The reason why you can only see one single line in the chart is because the phase delay curves for all five measurement positions are the same. Again, this is not a standard feature for current sensors on the market. Typically, the position of the wire core within the sensor does make a difference as you can see in graph 7. As you can see there is no phase shift compensation without a power analyzer to support the feature. But as you can also see only the combination of power analyzer and suitable current sensor allows you to perform a proper phase shift compensation in your measurements.

Figure 5: Typical sensors compared to HIOKI CT68 series

Figure 6: HIOKI CT68's phase delay and wire core position

Figure 7: Typical sensor's phase delay and wire position

Figure 8: Power Analysis - it takes two...

Therefore HIOKI power analyzers together with HIOKI current sensors are the perfect combination for your wide-band power analysis applications from DC to high frequency. Because like with a tango it takes two.

This article originally appeared in Bodo’s Power Systems magazine.

About the Author

Kai Scharrmann received his Diplom-Ingenieur Communication Engineering at FH Karlsruhe. He worked as a business development manager at HIOKI Europe GmbH