Predictive Models Support Planning for Infrastructure Maintenance Management

Mitsubishi Electric Corporation, Tokyo Institute of Technology and Kagoshima University announced today a basic technology that roadway and railway administrators will use to prepare highly tailored long-term maintenance and management plans for infrastructure. The technology is now being refined in cooperation with the city of Satsumasendai, Kagoshima Prefecture, where a verification test began this month targeting bridges managed by the city.

Going forward, tests involving a variety of bridges in Satsumasendai will be conducted to improve the accuracy of the technology. Application in other regions of Japan and for other types of infrastructure also is planned.

The technology was announced at a conference being held by the Japan Society of Civil Engineers in Japan to present research and hold discussions regarding the challenges of construction management.

New technology for preparing maintenance management plans

New technology for preparing maintenance management plans

Key Features

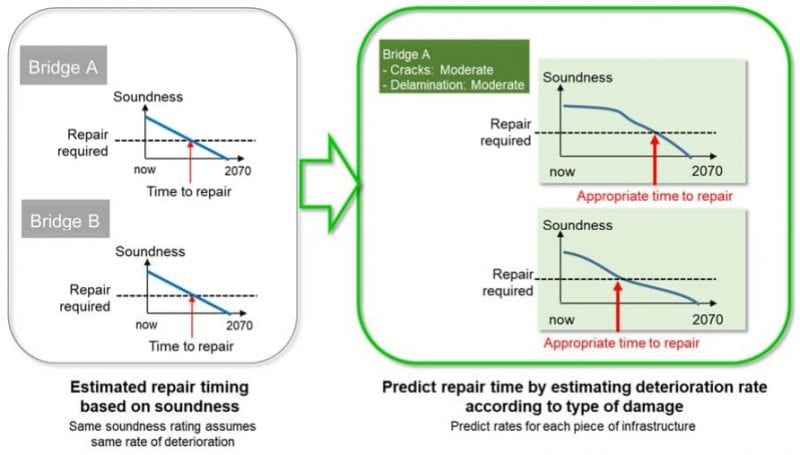

- Deterioration-rate model focuses on type of damage to predict infrastructure repair needs

Based on data and inspections of 538 bridges in Satsumasendai, a unique model is being refined to predict the rate of deterioration in concrete bridges, focusing on types of damage that have the greatest impact, such as cracks, concrete delamination and rebar exposure. The model identifies infrastructure degradation at an early stage and predicts when infrastructure will need to be repaired.

Prediction repair timing using deterioration-rate model

Prediction repair timing using deterioration-rate model

- Deterioration-cost model estimates costs of incremental repairs based on rate of deterioration

Repair methods and costs differ according to the type and degree of damage, such as depth of cracks and extent of concrete flaking. The deterioration-cost model estimates costs according to the type and degree of damage. By combining the repair-cost and deterioration-rate models, it will be possible to estimate repair costs according to the estimated rate of deterioration (Fig. 3). The technology, rather than determining standard repair costs, determines costs at the actual time of repair based on the estimated rate of deterioration, allowing for the visualization of costs and repair work aimed at preventing serious damage, including bridge collapses.

Repair-cost model that visualizes repair costs according to rate of deterioration

Repair-cost model that visualizes repair costs according to rate of deterioration

- Weighted objectives enable administrators to reflect priorities in maintenance plans

Administrators have a variety of infrastructure maintenance objectives, such as securing evacuation routes in disasters or preventing injuries from falling concrete. By expressing these objectives as indicators, such as repair level or financial loss, and then formulating the indicators together with the repair-cost model, it becomes possible to solve problems for optimized solutions. In turn, this will make it easier to create highly diverse plans, and budgets, for comparison purposes.

Moreover, it will be possible to make extensive calculations encompassing enormous infrastructure, including rates of deterioration, repair timing and repair costs. The calculations could be used to prepare multiple maintenance plans based on various maintenance objectives, thus enabling an overall plan to be evaluated on a multifaceted basis.

In addition, the weights of various indicators could be easily adjusted, such as increasing the level of repair, to create maintenance plans tailored to specific priorities.

Roles in Development Project

Mitsubishi Electric – Overall design, systematization, optimization algorithm development and verification summarization.

Tokyo Institute of Technology – Overall design, modeling of repair-cost model, and combination of repair-cost and deterioration-rate models in resulting deterioration-cost model

Kagoshima University – Overall design, analysis of infrastructure inspection data and modeling of degradation progress

Background

Extensive infrastructure built during Japan’s period of rapid economic growth is now deteriorated and in need of repair en masse. In 2014, the Ministry of Land, Infrastructure, Transport and Tourism mandated that local governments and road companies begin conducting regular visual inspections of bridges and tunnels every five years. The ministry is promoting a shift from post-repair maintenance to preventive maintenance involving frequent repairs aimed at preventing serious problems. Long-term preventive maintenance must be carefully planned, but such planning is very difficult to carry out manually for large-scale infrastructure.

Road bridges in Japan are currently categorized into four levels of soundness based on inspections, making it challenging to determine which infrastructure in the same category of soundness to repair first. Moreover, it is difficult to accurately reflect all priorities in maintenance plans because maintenance and management purposes can vary.