Oxford Instruments Partners with LayTec On Compound Semiconductors Devices

Oxford Instruments Plasma Technology and LayTec have announced a new partnership focusing on the development of compound semiconductor technologies.

The collaboration will see the companies work on the creation of advanced semiconductor devices in the high-volume manufacturing (HVM) environment.

The goal will be achieved by integrating LayTec’s accuracy and control technologies within Oxford Instruments’ wafer processing devices.

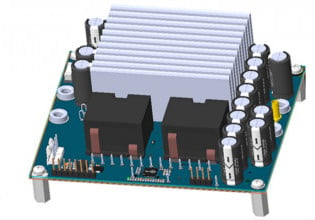

Image used courtesy of Oxford Instruments

Addressing the World's Most Pressing Challenges

Oxford Instruments is an international firm that specializes in the creation of technological products for a number of fields, including healthcare and agriculture.

“Our core purpose is to support our customers to address some of the world's most pressing challenges, enabling a greener economy, increased connectivity, improved health, and leaps in scientific understanding,” the company’s website reads.

Oxford Instruments has a long history of technological innovation. The company was founded in 1959 and has throughout the years completed a total of 13 different acquisitions, each aimed at supporting its development efforts in a different field.

Today, Oxford Instruments operates in two different segments, respectively Analytical and Superconductivity.

The first one provides measurement and fabrication instruments for industrial and commercial customers, while the second one offers materials, tools, and systems for industrial and government customers.

Pursuing Excellence in Integrated Metrology Solutions

LayTec, on the other hand, designs and manufactures metrology-based solutions enabling high yield and high-performance manufacturing, advanced process control, and related R&D.

Based in Berlin, Germany, LayTec was founded in 1999, and today counts more than 2000 metrology systems installed at customer sites in Asia, Europe, and the US.

The company specializes in the fields of semiconductors (particularly compound semiconductor applications and Silicon semiconductor thin-film characterization) and PV market and large-area coating.

Today, LayTec is one of the world market leaders in the field of in-situ metrology for LED and LASER production.

Developing Innovative Compound Semiconductors Devices

Compound semiconductor devices designed for the Internet of Things (IoT) and datacomms applications and based on materials such as GaAs/InP, SiC, or GaN are becoming increasingly widespread.

This is due to the fact that some designers see them as more power-efficient than their silicon counterparts.

However, their often-complex layer structure makes it harder to scale the technology for larger applications like wafers.

LayTec and Oxford Instruments are now joining forces to solve this issue by combining plasma process solutions with in-situ metrology to drastically improve device performance and thus enable a repeatable HVM process to shorten customers’ yield ramp.

In other words, Oxford Instruments’ stable plasma processing platform will be deployed alongside LayTec’s innovative and precise endpoint technology in plasma etching to enable the control and repeatability needed to increase the wafer-to-wafer yield.

“As we enter a very exciting period of innovation and growth, it is our firm intention to meet the requirement of improved performance and reduced cost of ownership objectives necessary to support needs of the emerging GaN power and RF market,” said Frazer Anderson, Innovations & Solutions Director at Oxford Instruments

“This collaboration with LayTec will further increase our ability to be able to deliver both requirements,” he added.

The new, long-term partnership will cover developments on the whole range of Oxford Instruments’ plasma etch and deposition systems.

The companies will also share rights to the Intellectual property (IP) produced and coordinated marketing activities, and deliver the first joint customer solution in the second half of 2021.