Nanomesh Material Promises Improvements in Batteries and Other Sustainable Applications

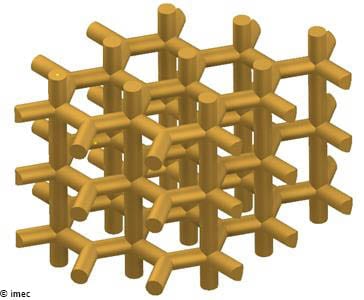

imec and KU Leuven, both partners in EnergyVille, announced a novel nanomesh material that could mean a breakthrough in a variety of sustainable-application sectors. The new nanomesh material is a three-dimensional nanometer-scale (metal) grid structure with highly regular internal dimensions. Above is a scanning electron-microscope image illustrating the highly regular structure.

Thanks to a combination of its unique material properties and the ease of manufacturing, it holds the promise to become widely applicable in (sustainable) industrial applications. Think about more efficient batteries, better catalytic converters, fuel cells and hydrogen production.

The nanomesh material is a 3D structure of nanowires that are horizontally interconnected on multiple levels, showing highly regular internal spacings and dimensions. As a result, it combines high porosity with an unprecedented surface-to-volume ratio. For each micrometer thickness, there is a 26-fold increase of available surface area.

To visualize this: when filling a volume of a small can of soda, it would remain 75% empty while containing a surface area equal to the size of a football field. On top of that, the internal and external dimensions can be tuned to almost any specification, making it potentially compatible with a multitude of application requirements.

3D impression of the grid structure.

3D impression of the grid structure.

Many industrial processes build on chemical reactions that (need to) occur at a surface. The more surface available, the more reactions that can occur simultaneously, and the higher the speed or throughput of the process. Think about electrodes in batteries, for example, transforming lithium into lithium ions.

imec’s nanomesh material can enable high-capacity and fast-charging batteries, because its large surface combined with high porosity features a high load of energy-storing material while it remains as a nanometer thin-film in close contact with the current collector.

Also, in fuel cells, the metal nano-grid structure of imec’s new nanomesh material could simultaneously act as a current collector and a functional catalyst. For example, in the electrolytic production of hydrogen from water, a few-micron of the new nanomesh material was shown to outperform a 300 times thicker nickel foam of about one millimeter thick.

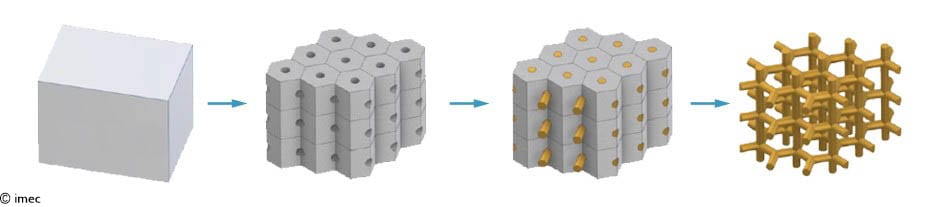

As a bonus, this unique material can be quite easily manufactured through cheap anodization and electroplating processes. First, a mold is formed by anodization of aluminum foil. The secret for the regular perforation at the nanoscale lays in the controlled doping of the aluminum metal. The resulting structure acts as a mold in which a large variety of materials can be deposited.

Nanomesh can relatively easily be produced through electrochemical processes at atmospheric pressure. First a mold is created in which the nanomesh material can be deposited, After etching, a free-standing nanomesh remains (click on image to enlarge)

Nanomesh can relatively easily be produced through electrochemical processes at atmospheric pressure. First a mold is created in which the nanomesh material can be deposited, After etching, a free-standing nanomesh remains (click on image to enlarge)

After consecutive chemical etching, the mold is being dissolved and a self-standing nanomesh structure remains. On a macroscopic level, the self-standing nanomesh is a flexible foil, giving it another edge over its closest competitors (metal foams and aerogels), which are often more rigid or brittle.

On a macroscopic scale, the material is flexible

On a macroscopic scale, the material is flexible

Prof. Philippe Vereecken, scientific director at imec and professor at the bio-engineering faculty of KU Leuven: “We have high expectations for this new nanomaterial. Its greatest strengths lie in the regularity of its structure, the large open structure and the conformability of its dimensions. We discovered the three-dimensional nanoporous structure almost 10 years ago, but only during the PhD research of Stanislaw Zankowski, the uniqueness of this material became clear. The spaces between the nanowires were small when using the traditional templated nanowire processes. Stan optimized the fabrication process to obtain the large porosity, so that it can now be optimally leveraged in many applications. We welcome all industrial parties who want to join us in transferring this very promising material into industrial applications.”