Mercedes-Benz Announces New Cobalt Supply Chain Practices

The German vehicle maker announced it will exclusively source cobalt and lithium from responsible mining-certified sites. Future generations of the company’s battery cells will reduce cobalt content to less than 10%.

Mercedes-Benz recently announced a significant change to its battery materials sourcing practices. In the future, the German vehicle manufacturer will only source cobalt and lithium from mining sites certified with the Standard for Responsible Mining, a set of social and environmental conditions for mining operations. Additionally, the company says its upcoming generations of battery cells will reduce cobalt content to less than 10%.

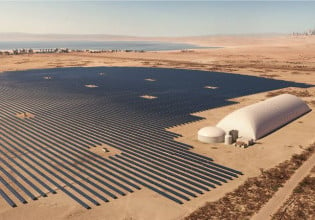

Image courtesy of Daimler.

Attractive for its stability, heat-resistance and anti-corrosive capabilities, cobalt has become the industry-standard raw material used for powering in-demand applications such as electric vehicles, laptops, smartphones and tablets. Lithium-ion batteries are the dominant end market for cobalt, growing from a 20% market share in 2006 to 51% in 2016, with 62% projected in 2020. One recent report by commodity research firm Roskill forecasts cobalt demand to roughly double in the next decade, primarily driven by battery applications. Another report from McKinsey & Company projects a 60% surge in cobalt demand between 2017 and 2025, assuming lithium-ion battery technology retains industry prevalence.

As demand for cobalt rises, the mining practices used to extract it have become the subject of considerable environmental and human rights concerns in central Africa’s Democratic Republic of the Congo (DRC). The DRC is the source of 60% of global cobalt mining, and about one-fifth of cobalt mined worldwide is extracted from unregulated mines in the country.

Such concerns have given rise to the Standard for Responsible Mining, a cross-industry set of principles established by the Initiative for Responsible Mining Assurance (IRMA). The requirements cover compliance with human rights and labor standards, occupational health, financial transparency, environmental and social impact, emergency preparedness and response, air quality, noise and vibration, greenhouse gas emissions, biodiversity and protected areas, waste and materials management, and more areas.

In 2018, Mercedes-Benz commissioned an outside advisory firm to identify 120 suppliers and conduct 60 audits of cobalt supply chain operations. Currently, none of the cobalt mines are certified under the Standard for Responsible Mining. As a result, the company will now incorporate sustainable raw material extraction and IRMA mining standards into its supply contracts and collaborate with development agencies and non-governmental organizations for improving mining conditions in high-risk areas. Mercedes-Benz will also limit the use of cobalt mines in the DRC and audit suppliers with IRMA’s Standard for Responsible Mining.

Additionally, future generations of Mercedes-Benz battery cells will reduce cobalt content to less than 10%, marking the beginning of the company’s use of post-lithium-ion technologies with new material compositions free of cobalt. Last year, Mercedes-Benz partnered with IBM Research to develop a battery made of cobalt and nickel-free material capable of outperforming existing lithium-ion batteries. IBM’s battery relies on three proprietary materials extracted from seawater, presenting a less invasive alternative to traditional material mining methods. IBM says the energy-dense battery can charge up to 80% in five minutes, with 90% energy efficiency.

In pursuing its CO2-neutral “Ambition2039” initiative, Mercedes-Benz considers the new responsible procurement standards for cobalt and lithium as only the first step. Future expansions will include other raw materials as well.

Mercedes-Benz isn’t the only company to announce new changes to its cobalt sourcing practices this year. At Tesla’s Battery Day event in September, CEO Elon Musk announced plans to eliminate cobalt from its battery cathodes, instead opting to mine lithium at a new 10,000-acre clay deposit site in Nevada. That announcement comes almost a year after Tesla was one of a handful of tech giants named in a lawsuit filed by Congolese families over the deaths and injuries of child workers at DRC mining sites.