Comparing the Cost of Chemistries for Flow Batteries

Researchers from MIT have demonstrated a techno-economic framework to compare the levelized cost of storage in redox flow batteries with chemistries cheaper and more abundant than incumbent vanadium.

Researchers from the Massachusetts Institute of Technology (MIT) have developed a techno-economic framework to compare competing redox flow battery chemistries that can be deployed quickly at grid scale and are capable of long-term operation to meet the demand for long-duration energy storage applications.

San Diego Gas & Electric (SDG&E) and Sumitomo Electric ran a microgrid pilot project in California using a vanadium redox flow battery. Image used courtesy of SDG&E

Battery energy storage technology is crucial for scalable renewable energy deployment since wind and solar resources are naturally intermittent and must be paired with storage to manage energy dispatch during peak demand. Flow batteries, which employ two tanks to send a liquid electrolyte through an electrochemical cell, pose a unique opportunity. One key selling point is flexibility in adjusting capacity levels, as upping the storage capacity only requires increasing the electrode quantity stored in the tanks, according to the International Battery Flow Forum.

While the first zinc-bromine flow battery was patented in the late 1800s, it’s still a relatively nascent market. The world’s largest flow battery, one using the elemental metal vanadium, came online in China in 2022 with a capacity of 100 megawatts (MW) and 400 megawatt-hours (MWh)—enough for 200,000 residents. Its operators plan to expand that capacity to 200 MW/800 MWh.

Power modules at the Dalian Flow Battery Energy Storage Power Station in China, the largest flow battery of its kind in the world. Image used courtesy of the Dalian Institute of Chemical Physics

The United States has some vanadium flow battery installations, albeit at a smaller scale. One is a microgrid pilot project in California that was completed in January 2022. The California Energy Commission awarded a $31 million grant to deploy a 60 MWh long-duration storage project incorporating a 10 MWh vanadium flow battery, a zinc hybrid cathode system, and other technologies.

Vanadium Flow Batteries vs. Alternatives

MIT Department of Chemical Engineering researchers are exploring alternatives to today’s popular vanadium-based flow batteries. That process requires a strong analysis of how much the initial capital cost will be, informing future adjustments for maintenance or replacement.

MIT highlights the work of Fikile Brushett, an associate chemical engineering professor whose lab studies advancements in electrochemical energy conversion and storage technologies. Brushett’s team is developing modeling frameworks to determine the cost, performance, and lifetime of redox flow batteries for grid storage applications by comparing different chemistries.

Vanadium is ideal for flow batteries because it doesn’t degrade unless there’s a leak causing the material to flow from one tank through the membrane to the other side. Even in that case, MIT researchers say the cross-contamination is temporary, and only the oxidation states will be affected. Minor adjustments can be made to rebalance the electrolyte volumes.

But vanadium comes with its own supply chain issues. As the adoption of long-duration energy storage grows, demand for vanadium will skyrocket. Pure vanadium is rarely naturally occurring, though, and it’s usually mined as a byproduct or is otherwise found in compounds. Current production is segmented in China, Russia, and South Africa. Its scarcity also drives up prices and adds volatility in the market.

Price of common vanadium-pentoxide sources (left) and the estimated price of electrolytes (right) used for vanadium flow batteries. Image used courtesy of the MIT Energy Initiative

Levelized Cost of Storage for Flow Battery Chemistries

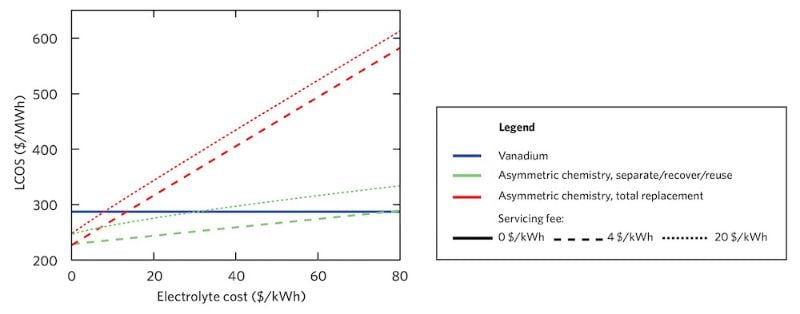

MIT researchers developed a framework to gauge the levelized cost of storage (LCOS) for different types of flow batteries. LCOS measures the average cost of electricity discharge for a given storage system, a useful tool for determining the investment required to install and operate the system over its lifetime.

The researchers have published several papers exploring the opportunities therein. A study published in the Journal of Power Sources analyzed the vanadium supply chain and found that gigawatt-scale deployment is possible over the next decade. However, it would require a historically unprecedented increase in production. The study outlined various opportunities to strengthen the supply chain and lower costs.

LCOS as a function of electrolyte cost, comparing a vanadium electrolyte baseline to an asymmetric system with finite-lifetime materials. The green line shows the remediation method of separating or recovering/reusing the decayed species, while the red line shows the LCOS of electrolyte replacement. Image used courtesy of the MIT Energy Initiative

In another study published in the Journal of Power Sources in 2021, researchers demonstrated an advanced version of their previous LCOS model that tracked capacity fade and recovery methods and estimated costs across the battery’s lifetime.

The new method provided remediation options for two classes of asymmetric chemistries—active species of finite or infinite lifetimes. In the former, the modeling suggested decay could be addressed through active-species replacement. In the latter case, the crossover could be addressed or eliminated by applying pseudo-symmetry using mixed electrolytes and other methods or using membranes with perfect selectivity.

_and_the_estimated_price_of_electrolytes_(right)_used_for_vanadium_flow_batteries.jpg)