Solar EnerTech Corp. announced that it had satisfactorily completed an assessment and review of the ongoing construction and installation efforts at its solar cell manufacturing plant in order to verify actual progress against the original development plan and target milestones.

The results of the assessment were better than anticipated and the entire project team is optimistic that as construction continues ahead of schedule the company should begin solar cell production during the 4th quarter of this year. The projected production capacity for the Shanghai-based facility is estimated at an output of 20 megawatts per production line. As the industry has seen recent price increases, the company currently estimates that each 10 megawatts of production translates into roughly $37.5 million in annual revenue. The company's strategic plan continues to project the initial line well into production before the end of fiscal 2006.

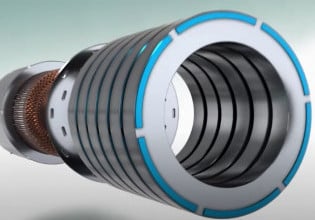

During the assessment, Solar EnerTech randomly examined and was satisfied with the status of the ceiling-mounted environmental air cooling units on the first and second floor of the plant. Nearly a hundred of these AC units make up an integrated system of temperature control inside the climactically sensitive manufacturing facility.

Solar EnerTech was also pleased to note that some new faces had joined the company. Effective July 1st, 11 university graduates enrolled by the company have begun their training program which includes overseeing numerous aspects of the critical installation and start up phase of the plant at Jinqiao Science and Technology Park. These graduates were recruited from Shanghai University and most of them specialize in micro-electronics and semiconductor applications.

Solar EnerTech concluded that all areas of its endeavor are moving quickly towards fruition of its near term manufacturing goals, as well as towards providing a vehicle to apply the outcome of its sponsored, university-based, and soon to be implemented in-house research directly into a production and distribution environment.