Battery Management System Transformer Design Reduces Open Failures in EV Apps

New BMS transformer from iNRCORE provides isolation and EMI suppression for EV battery management communications with improved reliability.

In the United States alone, EVs are projected to represent nearly 30% of all new car sales by 2030, or about 4.7 million EVs sold. Consumers will expect these vehicles, and their battery powertrains, to operate smoothly and reliably.

A hybrid engine. Image used courtesy of Pixabay

EV Battery Management System

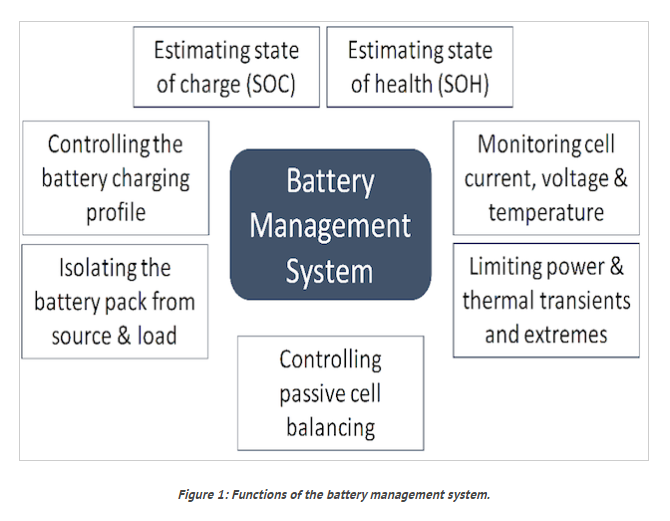

To achieve this, the Battery Management System (BMS) plays a critical role in ensuring the proper operation of an EV and its lithium-ion powertrain batteries. In addition to monitoring voltage and current levels for charge cycles and battery life, the BMS also measures temperature and overall battery health, communicating this data with the Central Processor Unit (CPU). Properly designed, the BMS can improve the reliability and performance of EV batteries and extend their operating life.

Functions of the battery management system (BMS). Image used courtesy of EE Power

Isolation and EMI Suppression for Data Comms

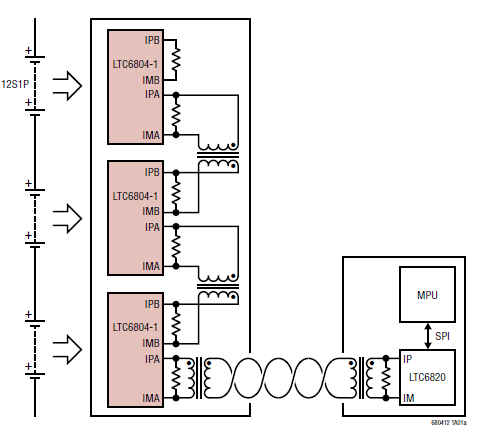

Battery status, data, and commands are typically communicated to and from the EV CPU via a wired interface (isoSPI, SPI, etc.). The high voltage levels of the battery, combined with the significant levels of electromagnetic interference (EMI) found in the EV powertrain, create a harsh environment for these communications. To meet safety requirements, and to ensure reliable communications between the BMS and CPU, a BMS transformer can provide both high voltage isolation (transformer) and EMI suppression (choke).

LTC6804-1 battery monitor uses BMS transformers for isolated daisy chain serial data communications with the CPU. Image used courtesy of Analog Devices

BMS Transformer Design Addresses Reliability Issues

One of the most common BMS transformer failure modes is open failure at wire termination, which disrupts data signaling. The new RA1055NL BMS transformer from iNRCORE addresses this issue by using spot welding and post-soldering processes to make these connections more reliable. After the transformer is coil wound, wires are spot welded to terminals melting the enamel wires for a more robust connection. Post-soldering further protects the connection from mechanical degradation due to oxidation.

RA1055NL mechanicals and electrical schematic (transformer and choke). Image used courtesy of iNRCORE

The RA1055NL is a single-channel BMS transformer that supports a 1 Mbps data rate with isolation up to 4300 VDC. In addition to safety isolation through the transformer windings and core, it also provides EMI noise suppression through an integrated choke to ensure data integrity. Using a filter capacitor and termination resistor with the center tap of the transformer further improves common mode noise rejection.

In addition to the ADI LTC6804/681X series, the RA1055NL is also designed for use with the NXP MC33771/33772 and TI BQ79616 battery monitors. The transformer supports isoSPI, SPI, and other serial communication protocols. Dual channel variants or devices with higher isolation levels can be custom developed as customer applications require.

The part has received AECQ-200 qualification for use in EVs and is available for new designs. Along with EVs, the RA1055NL can also be used for isolated serial communications in data centers, solar energy storage, and smart grid applications.

Daisy Chain Supports Modular EV Battery Designs

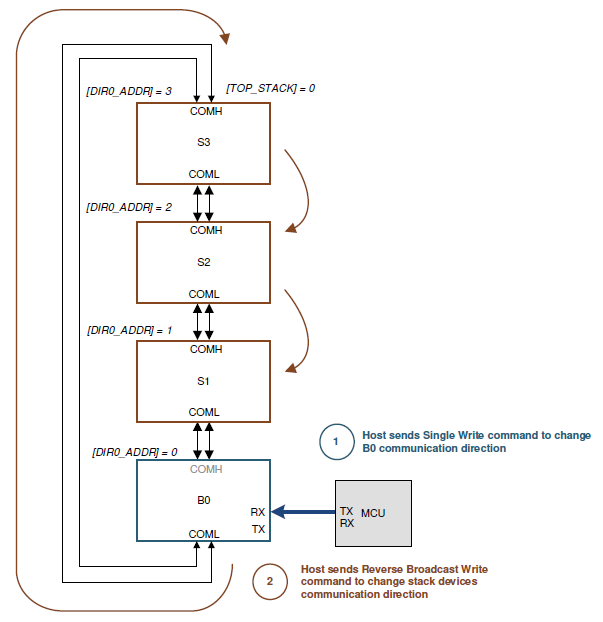

EV batteries are typically comprised of multiple modules or packs, each needing to communicate to the CPU through the BMS. Implementing this distributed communication via a traditional automotive CAN bus can be cumbersome. Accordingly, communication protocols like isoSPI were developed to offer better serial communications over longer distances and in harsh environments like EV powertrains. IsoSPI uses differential signaling on a twisted pair of wires, essentially eliminating external common mode interferers since both wires are impacted equally.

Managing daisy chain communications with the BQ79616 battery monitor. Image used courtesy of TI

A modular approach to EV battery design can also lead to extensive BMS wiring requirements. The ability to daisy chain communications from chip to chip significantly reduces wiring requirements for multiple modules to communicate with central processing. Ultimately, this capability allows designers to be more creative with EV battery implementations, optimizing cost, performance, space, and other key parameters.