Astrodyne TDI’s 3-Phase Power Supply Offers Flexibility, Precision

The three-phase input model of the MercuryFlex programmable power supply from Astrodyne TDI expands configuration options in industrial electronics, semiconductor fabrication, and medical equipment applications.

Astrodyne TDI has released a three-phase input variant of its 3.8 kW MercuryFlex programmable supply designed to deliver precision DC power in industrial electronics, semiconductor manufacturing, laser, and similar applications.

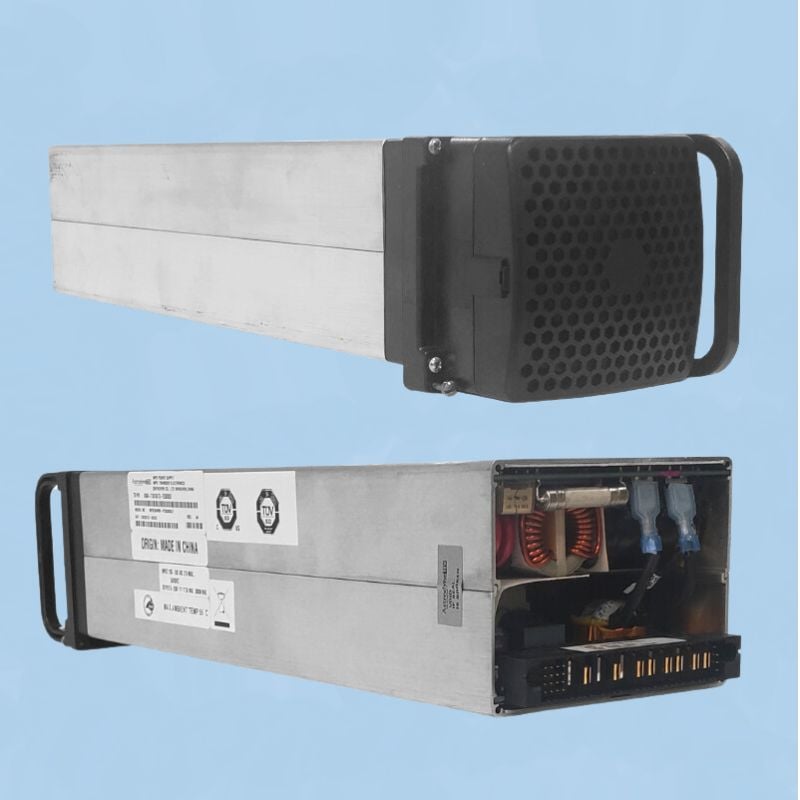

MercuryFlex 3.8 kW programmable supply module. Image used courtesy of Astrodyne TDI

The three-phase input capability introduces a layer of flexibility for the supply platform, accommodating three wire inputs and a wider AC input range.

The model is available in a compact 2U form factor that measures 4.25” x 3.42” x 15.20” and supports parallel operation of multiple supply modules to achieve higher power levels and system redundancy.

The MercuryFlex has a programmable DC output voltage ranging from 28 V to 450 V with wide-range precision control implemented through constant voltage, constant current, or constant power operating modes.

Power Solutions for Medical Applications

Along with semiconductor manufacturing, high-power LED, and other precision industrial applications, the MercuryFlex is targeted for medical platforms.

Image used courtesy of Astrodyne TDI

Astrodyne TDI has positioned itself as a leader in the medical power supply market with a decades-long history of manufacturing supplies for the medical industry. The company’s supplies, like the MercuryFlex, are designed to meet the stringent requirements of medical platforms such as ventilators, oxygen concentrators, therapy, and imaging platforms.

In addition to the functional requirements of output voltage and power, medical device power supplies must also meet strict design criteria, including BF and CF leakage requirements for patient safety, reinforced insulation standards, and manufacturing quality requirements.

MercuryFlex Programmable Supply

With the new model release, the MercuryFlex family of programmable power supplies supports single-phase, 50/60 Hz universal AC inputs up to 260 VAC and three-phase inputs up to 528 VAC.

Each module can deliver up to 3,800 W of power from a programmable DC output with nominal settings of 28 V to 450 V available across five models. This offers a high level of configurability for use in various industrial and medical applications.

The supply’s precision is defined by an output load regulation of 2% across the full load range and a peak-to-peak output voltage ripple of less than 1%.

Output settings are remotely controlled through a digital CAN Bus 2.0B interface and allow for control of the supply’s output at a constant voltage, current, or power (up to 160 A for a 28 V output).

Parallel and Redundant Operation

Automatic current sharing allows multiple supply modules to be operated in parallel in a shelf configuration for higher power outputs or for system redundancy. With a power factor above 0.90 and conversion efficiency greater than 91%, the MercuryFlex offers a high power density, delivering up to 15.2 kW of power in a 2U high, 19” rack space.

Multi-module shelf configuration. Image used courtesy of Astrodyne TDI

Each module within the multi-unit shelf configuration is hot-swap compatible to help ensure continuity of power.

Ensuring Safety

To ensure safe operation, the MercuryFlex incorporates a range of protective features, including input over/under voltage, input current, output overvoltage, and over-temperature protection.

The MercuryFlex complies with the latest UL 62368-1 and EN 62368-1 standards for quality and safety and meets the EMI requirements of FCC Part 15, Sub Part J, Class A; EN55022 and EN61000-3-2 to ensure minimal interference with local operating environments.