Powering Healthcare: Toyota-Kohler Collaborate on Hydrogen Fuel Cell System

Toyota and Kohler Power Systems merge technologies to create a hydrogen fuel cell system supplying critical hospital power.

Wisconsin-based Kohler Power Systems teamed up with Toyota Motor North America, the car giant’s U.S.-based arm, to develop a hydrogen fuel cell system for a hospital in southern Washington. The project will combine Toyota’s fuel cell modules with Kohler’s power generation control platform to balance the facility’s power needs with a reduced carbon footprint, emitting only water vapor.

The components provide complementary functions. Toyota’s fuel cell is designed to release direct current power, requiring Kohler’s controller to convert to alternating current power and synchronize with the grid. And while Toyota’s module has its own hydrogen and cooling controls, Kohler’s integration will optimize the operation.

Klickitat Valley Health in Washington State. Image used courtesy of Klickitat Valley Health

The installation will displace a diesel generator at the Klickitat Valley Health facility in Goldendale, the central hospital for more than 10,000 locals. In a virtual interview with Digitalisation World, representatives from Toyota and Kohler noted the project serves as a proof-of-concept for merging the pair’s hydrogen expertise.

Klickitat Valley Health initially contacted Kohler, seeking diesel alternatives to strengthen its electrical infrastructure with secondary generation and backup power sources. It had previously secured over $3 million from the Washington legislature to purchase a hydrogen fuel cell for a renewable-based microgrid. The funding allocation included electrical upgrades and smart grid projects with up to 100 kW of fuel cell generation.

The project’s next stage will reportedly combine the Toyota-Kohler fuel cell system with a microgrid.

Kohler’s Control System

Kohler designed and manufactured a versatile controller to continuously monitor operating conditions while ensuring reliable performance for Toyota’s fuel cell. The control system interoperates with building management systems. Kohler plans to complete system integration and plant balancing to confirm all components and auxiliary systems are running as expected.

Kohler’s hydrogen fuel cell power system. Image used courtesy of Kohler (Page 1)

Kohler’s Fuel Cell System can serve peak shaving, prime, and emergency functions. It’s also flexible, with custom options for individual installations or entire facilities.

The project builds on the company’s experience supplying controls and integration for its existing fuel cell products. Kohler already markets a solid polymer electrolyte membrane fuel cell for high-efficiency hydrogen conversion. The system boasts low maintenance with a 20-year design life, a power output ranging from 100 kW to several megawatts, and flexible operations in various temperatures from -22 to 113°F. It uses Kohler’s APM802 controller, featuring a graphical user interface and touchscreen.

Kohler’s APM802 hydrogen fuel cell system controller. Image used courtesy of Kohler

Toyota’s Fuel Cell Module

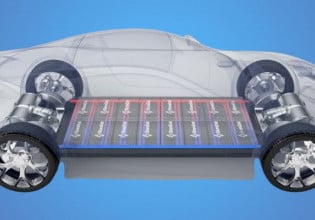

Toyota’s compact fuel cell module features components from its second-generation Mirai sedan, a hydrogen fuel cell EV introduced in 2020. In the Digitalisation World interview, Toyota said the hospital’s module design reused all the same components from the Mirai vehicle, with slight control adjustments. The fuel cell could still power up quickly, thus serving the primary function of backup generation.

The second-generation version improved on the first’s fuel cell stack and system cooling, onboard power control, and other components. It also upped the power output by 12% from 114 to 128 kW, translating to 182 horsepower compared to the predecessor’s 151.

The second-generation Mirai fuel cell. Image used courtesy of Toyota

While still 650 V, as in the first Mirai, the second-generation fuel cell stack added several improvements to make the model 20% smaller and 50% lighter. The compact stack enabled the transition from front-wheel drive to rear-wheel drive. The new layout offered more hydrogen storage space to boost the range to 402 miles, up 30% from the first generation.

The hospital project allows Toyota to demonstrate its hydrogen fuel cell modules for stationary power applications. The company has long been at the forefront of the fuel cell market, debuting its Mirai fuel cell model in 2015. It’s also expanding the technology for larger powertrains in heavy-duty trucks.