A Battery Management System For 800 V Electric Vehicles

Supplier Sensata Technologies has an off-the-shelf Battery Management System solution available for the next generation of electric vehicles.

The key to the safe and efficient operation of modern lithium-ion batteries is an effective battery management system (BMS).

Lithium-ion batteries, particularly the higher power versions with nickel-based cathodes (positive electrodes), can suffer damage if they are overcharged or undercharged or get too hot during operation. Monitoring the charge level of each cell, actively balancing that level between cells, and protecting against excessive temperature buildup are some tasks assigned to a BMS.

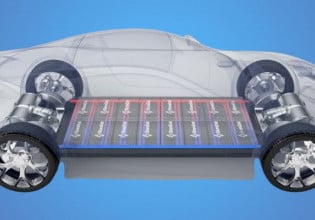

Image used courtesy of Sensata Technologies

Increasing EV Voltage

A decade ago, when EVs were just getting started, electrical systems carried around 200-300 volts. More recent EVs are built with 400 V systems, and a handful of EVs like the Porsche Taycan and Hyundai Ioniq 5 run with batteries that produce 800 V.

Increasing the voltage allows for smaller and lighter electrical cables with the same power level (with less current) and decreases charging times. Most automakers have committed to an 800-volt future.

The increase to 800 volts is also attractive for trucks and buses where, combined with high current, it can produce extremely high torque levels to help carry heavy loads. As the voltage and current levels increase, however, the need for a highly accurate BMS designed for the application becomes more important.

The Sensata Battery Management System

One example of a new BMS designed for these demanding performance levels has been introduced by Massachusetts-based supplier Sensata Technologies. Its new Lithium Balance n3-BMS can deal with up to 1000 volts and 2000 amps while also being equipped with software that can be customized and adapted to meet various needs. The Sensata BMS is designed specifically for buses, heavy and medium duty trucks, and a range of other commercial vehicles.

ISO Certification

Beyond the actual performance of the components of an EV, they must also meet the requirements of ISO 262262, an international standard titled Road Vehicles-Functional Safety. This standard deals with the electronic and electrical systems that are installed in road-going vehicles, including trucks and buses. Certifying components and systems to meet ISO 26262 is both complex and costly. The certification is also very time-consuming and can take years to complete. The off-the-shelf Sensata n3-BMS provides an ISO 26262 certified solution resulting in an Automotive Safety Integrity Level (ASIL C) certification without requiring additional costly and lengthy testing.

The distributed system can handle up to 30 Cell Monitoring Units (CMUs) that keep track of individual cells along with a Master Control Unit that brings together data from various sources and controls the battery functions.

The adaptability of the n3-BMS comes from its ability to accept a customer’s coding and performance algorithms without changing the ISO certification. A Sensata base software layer (BSW) provides the safety-critical features and functionality of the BMS while an external software layer (ESW) is accessible to the user to configure the BMS to its specific application. The n3-BMS can monitor between 24 and 300 individual battery cells in series and offers three CAN ports for digital communications.

Standardizing EVs

As electrification becomes more mainstream, there will be more suppliers like Sensata that will be able to provide ISO-certified solutions to a variety of needs and requirements. In the long run, this will help to standardize much of the behind-the-scenes, under-the-hood componentry and will ultimately strengthen the transportation industry and its goal to reach zero emissions.