Minimizing Quiescent Current With Automotive Linear Regulators

Linear regulators maintain a fixed output voltage using a feedback system to dynamically adjust series resistance, inducing the exact voltage drop necessary at a given load current to realize and maintain the desired output voltage. Regulators with small dropout voltages are important in systems where energy efficiency is a factor.

This article is published by EEPower as part of an exclusive digital content partnership with Bodo’s Power Systems.

Linear regulators are ubiquitous electrical circuit elements whose function is straightforward—maintaining a fixed output voltage in the presence of variation, including changes in input voltage, load current, and environment. Linear regulators use a feedback system to adjust series resistance dynamically, thus inducing the exact voltage drop necessary at a given load current to realize and maintain the desired output voltage.

Image used courtesy of Adobe Stock

Linear Regulator Performance

Though simple in concept, these devices have garnered the attention of advanced chip designers in an ongoing effort to optimize performance regarding efficiency, dynamic response, size, and cost. This has grown especially relevant in the automotive industry, where many circuits and subsystems are required to operate 24x7 directly from the primary battery. As such, static power consumption, dynamic performance, and physical implementation size have become primary low dropout (LDO) figures of merit.

Linear regulators are often characterized by their output voltage (fixed or adjustable), input voltage range, and output current capability. Another more nuanced characteristic is the dropout voltage, or the minimum achievable difference between the input and output voltage, while still providing regulation. Regulators with small dropout voltages, or LDO, are important in systems where energy efficiency is a factor. In these same energy-constrained designs, the current drawn by the internal functions of the regulator must be carefully considered and minimized. This quiescent current (Iq) must be small—relative to the current drawn by the load—to achieve an efficient design.

Since linear regulators rely on a feedback system, stability must be considered to prevent oscillation under certain load conditions. Typically, some output capacitance is required to guarantee stable regulation over the entire operating range. Output capacitance, however, can be expensive in terms of circuit complexity and physical size. Advanced regulator designs have been developed to minimize the amount and quality of the output capacitance required, yielding excellent performance at the smallest possible size and lowest possible cost.

Figure 1. ROHM’s Package Lineup for LDO Regulators. Image used courtesy of Bodo’s Power Systems [PDF]

Finally, when discussing practical applications of linear regulators, environmental tolerance must be considered at the forefront of the design phase. This includes the package characteristics of the regulator, not only in terms of physical size but also in the ability to remove heat and reliably operate under the harshest conditions of temperature, humidity, and vibration.

Automotive Electronics Council Q100 (AECQ100) sets forth the testing criteria for devices to be certified for automotive applications. This standard includes rigorous testing for temperature, humidity, vibration, electrostatic discharge, and various other reliability-focused criteria.

The LDO Evolution

Depending on the application, LDOs can be optimized to achieve specific performance goals while trading off other parameters, most commonly physical size and cost. ROHM has developed several proprietary technologies that provide best-in-class performance. LDOs featuring Nano Energy technology use advanced circuit techniques to minimize quiescent current. For energy-constrained applications, the active losses of these LDOs far exceed parasitic losses, resulting in the highest possible efficiency. As shown in Figure 2 below, ROHM’s devices feature nearly 50% lower quiescent current than the next-best competitor. While the difference between 1.9 uA and 850 nA may seem insignificant, it can translate to massive lifetime gains for battery-operated devices with advanced sleep modes and low-duty cycles.

Figure 2. ROHM’s Nano Energy technology minimizes quiescent current. Image used courtesy of Bodo’s Power Systems [PDF]

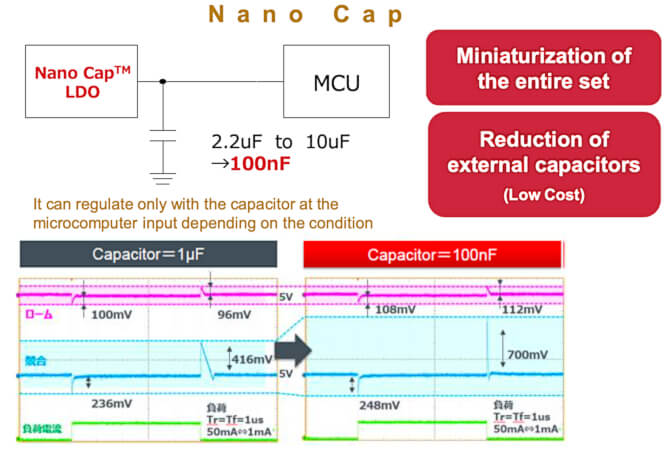

In volume-constrained applications, where the size of every component must be accounted for and justified, Nano Cap technology eliminates the need for external LDO capacitance. Typically, LDOs require several output capacitors ranging in size from several hundred nF to 10 mF. These capacitors are expensive and can occupy more printed circuit board space than the LDO itself. As shown in Figure 3, Nano Cap regulators offer equivalent overshoot and undershoot performance during load transitions using only the parasitic capacitance of the load circuit.

Figure 3. ROHM’s Nano Cap technology reduces output capacitance requirements. Image used courtesy of Bodo’s Power Systems [PDF]

Since many LDOs operate adjacent to common circuit blocks found within digital and mixed-signal systems, it makes sense to integrate these blocks into the LDO itself. Figure 4 illustrates voltage output trackers, watchdog timers (WDT), reset controllers, and common automotive communication buses such as LIN and CAN.

Figure 4. Multi-function integration saves space and reduces cost. Image used courtesy of Bodo’s Power Systems [PDF]

BD4x/BD7x Series

ROHM’s BD4x automotive LDOs fall into the standard series of devices, featuring an absolute maximum input voltage of 45 V with an output voltage accuracy of ±2%. As such, these regulators are well-suited for automotive applications requiring a direct connection to the battery. The BD7x series is similar but offers reduced quiescent current (typically around 6.0 μA), making it an ideal candidate for powering subsystems that run continuously like the one shown in Figure 5.

Figure 5. ROHM’s BD4/BD7 Series LDOs for automotive subsystems. Image used courtesy of Bodo’s Power Systems [PDF]

For example, the BD7xxL05G-C features an input voltage of 3.0 V to 42 V, up to 50 mA output currents, an operating temperature range of -40 °C to +150 °C, and AEC-Q100 qualification. Available in an ultra-compact 2.9 mm x 2.8 mm x 1.25 mm SSOP5 package, these LDOs can be readily integrated into automotive infotainment and other similar subsystems to provide supervisory, always-on operation.

BD8x Series

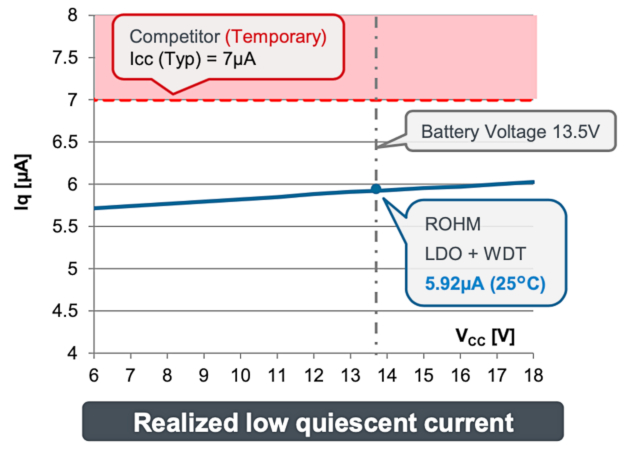

For when added functionality is required for battery-powered automotive subsystems, ROHM developed the BD8x series of LDOs. Much like the BD7x series, these regulators are built on a technology platform that realizes extremely low quiescent current. The same Iq of 6.0 μA is achieved while incorporating a watchdog timer, output voltage monitor, overcurrent protection, and thermal shutdown circuitry. For example, the internal block diagram of the BD820F5UEFJ-C is shown in Figure 6.

Figure 6. BD820F50EFJ-C internal block diagram. Image used courtesy of Bodo’s Power Systems [PDF]

The topmost pins (VCC and Vo) perform LDO regulation, while the Reset Out (RO) pin indicates a necessary reset to downstream circuitry—a microcontroller or FPGA, for example. The remaining pins (CT, CLK, and INH) control the onboard watchdog timer, set the watchdog RC time constant, monitor the downstream clock signal, and inhibit the reset mechanism, respectively. As shown in Figure 7, this LDO and all supporting supervisory circuitry still consume less than 6.0 μA of current with an automotive battery input voltage of 13.5 V.

Figure 7. BD8x current consumption vs. the competition. Image used courtesy of Bodo’s Power Systems [PDF]

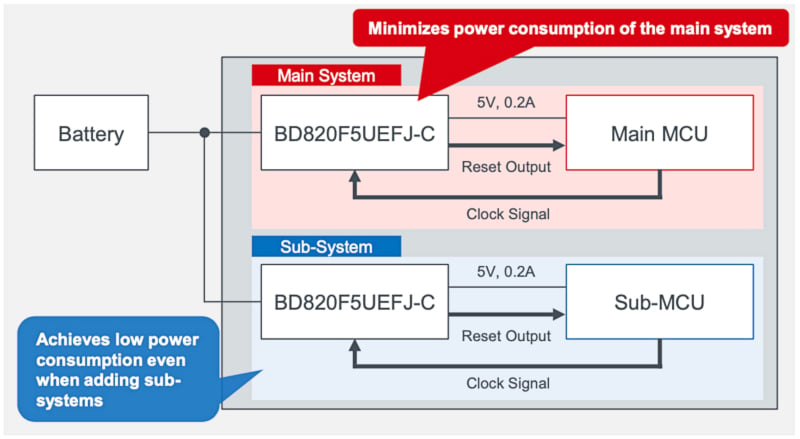

This low quiescent energy dissipation makes the BD8x series an ideal candidate for battery-connected automotive subsystems (see Figure 8). Eliminating the need for external watchdog timers and voltage monitors reduces overall system complexity while achieving maximum efficiency.

Figure 8. BD820F5UEFJ-C performing LDO and supervisory controller duties. Image used courtesy of Bodo’s Power Systems [PDF]

As an example of BD8x series capabilities, the BD820F50EFJ-C offers an operating input voltage range from 3.0 V to 42 V, an output current of up to 200 mA (at 5.0 V), and an operating temperature range of -40 °C to +150 °C. Available in a 4.9 mm x 6.0 mm x 1.0 mm package, it is AEC-Q100 qualified and protected from overcurrent and over-temperature conditions.

BD9x Series

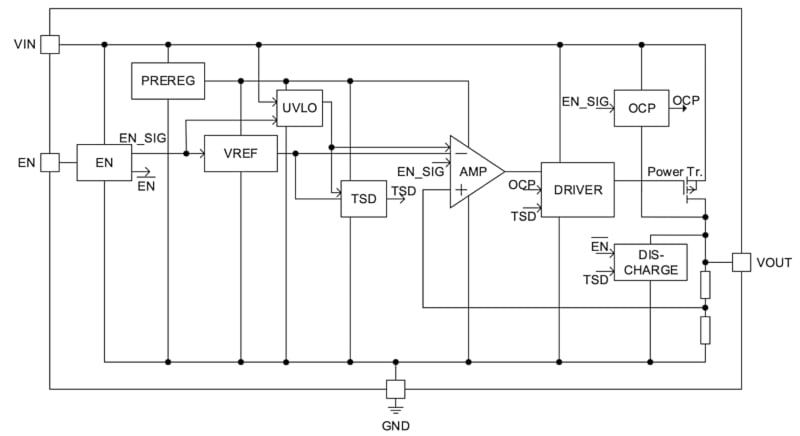

ROHM’s most advanced automotive LDO lineup is the BD9x series, featuring the proprietary QuiCur and Nano Cap technologies. QuiCur is a control method that maximizes the response performance of power supply ICs to improve transient overshoot and undershoot during load changes. Similarly, Nano Cap improves stability and load response while reducing output capacitor requirements. In keeping with the theme of low energy for automotive applications, the BD9x series also offers extremely low quiescent current and AEC-Q100 qualification.

Figure 9 shows the block diagram for BD9xxN1yy-C. This regulator appears typical from the outside with voltage input, voltage output, and enable pins. Internally, however, Nano Cap control circuitry provides extremely tight regulation using output capacitors as low as 100 nF.

Figure 9. BD9xxN5yy-C block diagram. Image used courtesy of Bodo’s Power Systems [PDF]

To illustrate this level of performance, Figure 10 depicts two scenarios, the first with an output capacitor of 2.2 uF and the second with 100 nF. In the larger capacitance comparison, BD9x shows a nearly 5x improvement in peak ripple during transient load changes. With the smaller capacitance, the competitor’s LDO fails to regulate and becomes unstable, while the BD9x shows a peak overshoot of only 64 mV.

Figure 10. Nano Cap dynamic performance in the BD9x Series. Image used courtesy of Bodo’s Power Systems [PDF]

Achieving this level of dynamic performance with such a small output capacitance—while consuming just a handful of microamperes of quiescent current—puts the BD9x series in a league of its own among automotive LDOs. These advantages enable new applications in low-energy subsystems while minimizing cost, physical size, and design complexity.

Low-Quiescent Linear Regulator Takeaways

With the ever-growing complexity and prevalence of electronics in automotive systems, LDOs have taken on an important role in the quest for energy-optimized, low-cost components. This is especially true in automotive subsystems, where always-on and supervisory circuits must be carefully designed to run from the battery directly for long periods. Low-quiescent current LDOs satisfy these needs, offering solutions for virtually all circuit types ranging from the more generic BD4x series to the specialized high-performance BD9x series. With AEC-Q100 qualification and wide operating and environmental margins, designers can be sure to find an LDO that will fit any automotive application.

This article originally appeared in Bodo’s Power Systems [PDF] magazine.