GM Previews Hydrogen Fuel Cell Truck, Infrastructure for Fleets

General Motors enters the next stage of its federally-funded hydrogen fuel cell pilot, targeting medium-duty trucks.

Michigan car giant General Motors envisions a hydrogen-centered fleet worksite solution for the next stage of its Department of Energy (DOE)-funded fuel cell pilot program. In addition to developing medium-duty trucks powered by its Hydrotec fuel cells, the company will supply infrastructure for hydrogen refueling and production.

The field evaluation fleet trucks will be built with a frame similar to the 2024 Chevrolet Silverado 5500, with a 19,500-pound gross vehicle weight rating, including cargo capacity, and operate in an 800 V architecture with more than 300 kW of peak power.

GM’s prototype Hydrotec fuel cell-powered truck. Image used courtesy of GM

The prototypes' range will be at least 300 miles, depending on ambient temperature, battery condition, terrain, loading, and other factors.

The U.S. Army’s Ground Vehicle Systems Center is providing additional funding for the project’s fuel cell propulsion systems.

GM’s Hydrotec fuel cell. Image used courtesy of GM

Fuel Cell Advantages for Fleets

Fuel cells, which convert stored hydrogen energy into electric power, are useful in truck fleets because of their light weight, efficiency in electron storage, ability to carry heavy payloads, and quiet operation with fewer moving parts. They’re a clean alternative to diesel fuel, offering zero tailpipe emissions and comparable capabilities in towing and handling large payloads.

Hydrogen fuel cells can support long-range trucking needs. According to estimates from the North American Council for Freight Efficiency, the optimum duty-cycle sweet spot for hydrogen-powered long-distance freight hauling involves a 200- to 650-mile range with a freight payload of up to 48,000 pounds. (For reference, light-duty fuel cell cars capable of a 300-mile range are already available in the consumer market. According to DOE data, recent models from Hyundai’s Nexo and Toyota’s Mirai series offer 330 to 402 miles.)

Unlike battery electric vehicles (BEVs) that rely on overnight charging sessions, fuel cells enable fast refueling. More fleets are adopting them for medium- and heavy-duty trucks, buses, mining equipment, and forklifts. For example, Amazon recently commissioned an on-site electrolyzer to power more than 225 fuel cell-propelled lift trucks at a fulfillment center in Colorado.

A proton exchange membrane (PEM) electrolyzer will supply the hydrogen for GM’s upcoming pilot prototype. PEM electrolysis enables a high-purity output by splitting water into hydrogen and oxygen. Electrolyzers powered by renewable energy sources have no carbon footprint, as oxygen is the only byproduct. This configuration is termed green hydrogen, distinct from grey and blue hydrogen produced with fossil fuels.

Fuel cells operate on the opposite electrochemical sequence. The reaction combines hydrogen gas (supplied to the anode) and oxygen (collected by the cathode), separated by an electrolyte, to generate electricity. The process only emits water vapor.

GM’s Pilot To Include a Microgrid and PEM Electrolyzer

Southern Company, a utility operating in six states, will use the Hydrotec trucks as shop vehicles across its worksites. Southern Company subsidiary Georgia Power will develop a microgrid with a mobile power generator and a stationary fuel cell to demonstrate GM’s integrated hydrogen configuration for refueling infrastructure. The microgrid will be installed at an unspecified power plant in Georgia.

The demonstration aims to apply the microgrid concept to release hydrogen during off-peak hours, serving the site’s operations when power from the grid is more expensive due to high demand. In addition to the Hydrotec vehicles, the fuel cells will power the site’s 350 kW fast charging system for medium-duty BEVs.

This won’t be the first time GM deploys its Hydrotec fuel cells for medium- and heavy-duty vehicles. Its GM Envolve subsidiary supplies custom Hydrotec systems for rail, aircraft auxiliary power, trucking, and heavy machinery applications. GM has also built Hydrotec-based power generators for fast-charging stations.

Two views of GM’s Hydrotec fuel cell architecture. Image used courtesy of GM

Norway-based Nel ASA will contribute its advanced PEM electrolyzer to produce green hydrogen on-site. Nel’s PEM electrolyzers offer a small physical footprint, minimal maintenance requirements, and a variable output that responds quickly to changes in energy demand.

GM and Nel originally signed an agreement in November 2022 to jointly develop PEM cell stacks with improved equipment durability and production efficiency at a reduced Levelized Cost of Hydrogen. According to Nel’s latest annual report, the GM partnership comprises seven milestones, two of which were achieved last year. When presenting its 2023 results to investors recently, the company mentioned that its electrolyzer division verified the feasibility of its next-generation PEM stack targets in collaboration with GM.

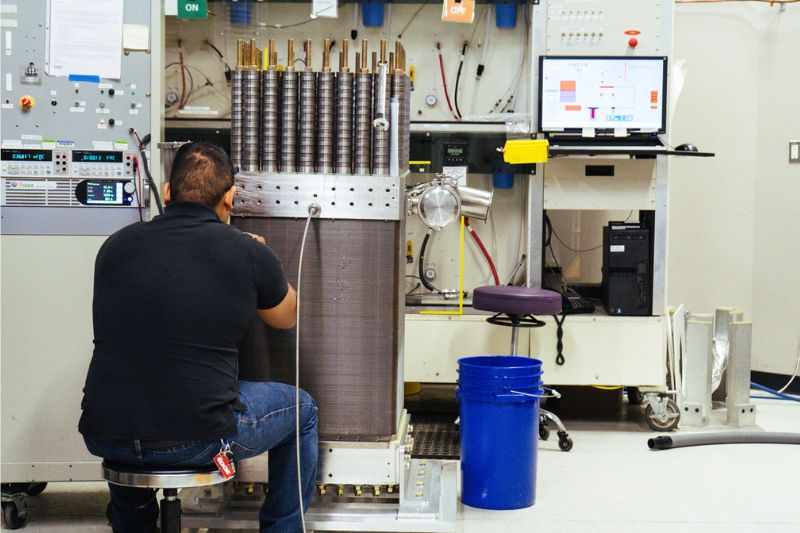

A Nel ASA engineer works on a PEM hydrogen electrolyzer. Image used courtesy of Nel

Last year, Nel selected the Detroit suburb of Plymouth for its gigafactory. The facility is within a short distance of GM’s headquarters, and its announcement emphasized the advantage of sitting the facility close to GM’s Hydrotec development.

The DOE recently awarded Nel $50 million to support the gigafactory, which will manufacture the next-generation PEM stacks co-developed with GM. The site will have 4 GW of annual production capacity once completed.