Understanding PV System Standards, Ratings, and Test Conditions

Learn about PV module standards, ratings, and test conditions, which are essential for understanding the quality and performance of photovoltaic systems.

PV modules adhere to specific standards to ensure safety and reliability. These standards include compliance with industry regulations such as UL 1703 and IEC 61215. Modules must be labeled with ratings indicating their performance characteristics, such as maximum power output and operating voltage. Testing conditions, like standard test conditions (STC) and standard operating conditions (SOC), are used to assess module performance under standardized parameters, ensuring accurate evaluation.

Image used courtesy of Adobe Stock

Diodes in PV Systems

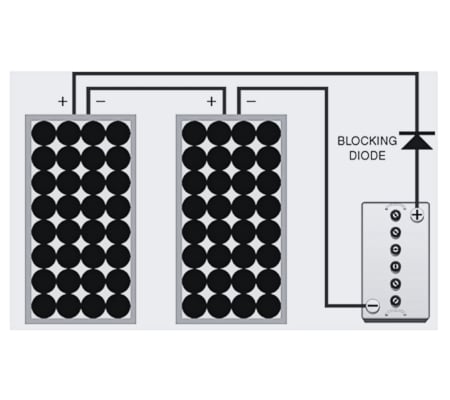

Most charge controllers already have blocking diodes or can perform this function in some other way, so a PV system electrical installer does not often have to install blocking diodes. A diode is a semiconductor device that current can pass through in only one direction. Blocking diodes (Figure 1) are placed in the positive line between modules and the battery bank to prevent the battery current from reversing its flow from the battery bank to the array at night or during cloudy weather.

Figure 1. Blocking diodes are placed in the positive line between modules and the battery bank (if used) to prevent current from reversing its flow from the battery bank to the array at night or during cloudy weather. Image used courtesy of Ahmed Sheikh

Bypass diodes (Figure 2) are wired in parallel with a module to divert current around the module in the event of too much shading. Even with the use of bypass diodes, shading can greatly reduce the performance of a PV module. Sometimes, they are embedded in the module laminate in the manufacturing process and cannot be accessed for service. Other manufacturers install them in a junction box attached to the module. If you install them yourself, they should be sized to handle at least twice the maximum current they are expected to carry and sized for at least twice the voltage applied to them.

Figure 2. Bypass diodes are wired in parallel with a module to divert current around the module in the event of too much shading. Image used courtesy of Ahmed Sheikh

PV Module Standards and Codes

PV modules installed in the United States must conform with Underwriters Laboratories (UL) 1703 Safety Standard for Flat-Plate Photovoltaic Modules and Panels. This standard applies to roof-mounted, ground-mounted, pole-mounted, or integrated-mounted modules used in a PV system with a voltage of 1000 volts or less.

The National Electrical Code applies from an installation standpoint. Article 690 specifically covers PV systems, but many other sections in the NEC must also be applied when installing a PV system.

During the module manufacturing process, standards like the International Electrotechnical Commission (IEC) 61215 Crystalline Silicon Terrestrial Photovoltaic Modules—Design Qualification and Type Approval are followed to ensure product quality. Another standard is IEC 61646 Thin-Film Terrestrial Photovoltaic Modules—Design Qualification and Type Approval. Following these standards allows manufacturers to produce a high-quality module warranted for 20 years or more. Typically, the warranty guarantees an 80 percent module output of the nameplate ratings over 20 years. That means only about a 1 percent reduction in module output each year.

PV Module Ratings

A manufacturer can determine standard performance ratings for each PV module based on a series of tests. Section 690.51 of the NEC requires these ratings to be clearly labeled on each module. Each module label must be marked with the polarity of the connections, maximum fuse or circuit breaker rating, and other ratings, including the open circuit voltage (Voc), operating voltage (Vpmax), maximum permissible system voltage, operating current (Ipmax), short circuit current (Isc), and maximum power (Pmax). The label may contain other information, such as fire class rating and wire sizes if a manufacturer chooses. The information on the label is used in the system design process.

PV Module Test Conditions

When determining peak performance numbers for a PV module, manufacturers test their products using specific conditions so the data is reliable and repeatable during a series of tests.

The reference condition called standard test conditions (STC) is commonly used and assumes 1000 W/m2 solar irradiance, AM1.5 spectrum, and a cell temperature of 77°F(25°C). AM1.5 spectrum refers to a 1.5-atmosphere thickness (air mass or AM) corresponding to a solar zenith angle of around 48°. Remember, the solar zenith is when the sun is directly above a PV module (or array), at which point the sun’s rays travel the shortest distance through the atmosphere to strike the PV modules. During most of the day, the distance through the atmosphere is greater than the zenith distance because the angle between the PV modules and the sun changes as the sun moves across the sky. AM1.5 represents the overall yearly average for mid-latitude locations like the United States. As a result, the solar industry uses AM1.5 for all standardized testing of solar panels.

The PTC reference is based on a solar irradiance of 1000 W/m2, an ambient temperature of 68°F(20°C), and a wind speed of 1 meter/second (m/s). Because the PTC reference uses more realistic parameters, the peak output numbers for PV modules tested using the PTC numbers will be lower than the STC numbers.

Another reference condition is called standard operating conditions (SOC). It is similar to the STC reference but uses the nominal operating cell temperature (NOCT) instead of 77°F(25°C). It is also very similar to the PTC reference but uses a more realistic solar irradiance. The NOCT is based on a solar irradiance of 800 W/m2, an ambient temperature of 20°C (68°F), and a wind speed of 1 meter/second (m/s). Because the SOC reference uses more realistic parameters, the peak output numbers for PV modules tested using the SOC numbers will be lower than the STC numbers. When you look at a module’s I-V curve, know whether it is done under STC or SOC conditions.

Nominal operating condition (NOC) is another reference condition using a solar irradiance of 800 W/m2, an AM 1.5 spectrum, and a nominal operating cell temperature. The NOC reference gives a more realistic set of operating numbers. Again, be sure that when looking at the ratings of a PV module, you know which testing condition was used.

Takeaways of PV Modules

The standards and test conditions discussed here are vital in ensuring the safety, reliability, and performance of photovoltaic modules. Adhering to industry standards like UL 1703 and IEC 61215 helps maintain the quality and compliance of PV modules, ensuring they meet regulatory requirements. Labeling modules with performance ratings provide valuable information for system design and installation, enabling professionals to select appropriate components for specific applications. Moreover, standard tests and operating conditions allow for accurate evaluation of module performance under controlled parameters.