Since the first introduction of the DIPIPM™ (Transfer molded type intelligent power module) product family in 1997, these products have been continuously improved and further developed. In the meantime, seven DIPIPM™ product groups have been created in different housing designs, current and voltage classes.

Introduction

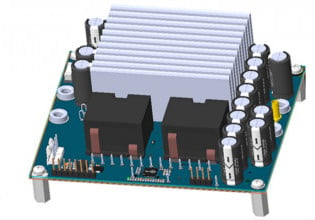

A wide motor power range up to 15 kW for different motor voltages is covered by the DIPIPM™ product family. These products are now used in numerous applications such as servo and standard drives, air conditioning systems, refrigerators, fans and washing machines.

A unique feature of these products is the high degree of integration of functions with numerous control and protective measures, such as under-voltage protection, over-temperature detection and short circuit protection.

As the number of household appliances increases, so does the need for cost-effective and integrated solutions. Customers want to utilize the recent chip developments in their products as quickly as possible and bring them to market to benefit from the increased efficiency and cost advantages. In addition, these products with the high integration of functions offer better reliability compared to discrete solutions. The SLIMDIP™ product group is the best choice to achieve the above customer targets.

SLIMDIP™ Products Line-up and Features

The SLIMDIP™ product group, introduced in 2015 [1], has recently enjoyed particular popularity. Due to this fact, Mitsubishi Electric is developing further products in the same package with additional current ratings.

In addition to the already presented SLIMDIP-S (5 A), SLIMDIP-L (15 A regular frequency) and SLIMDIP-W (15 A high frequency), next additional products are coming onto the market. It is the SLIMDIP-M with a 10 A current rating for high switching frequencies. Further current ratings are under development already.

The common SLIMDIP™ product features are:

- control input interface compatibility to 5 V and 3 Vhigh isolation voltage of 2000 Vrms, one minute

- integrated bootstrap circuit with diodes and current limiting resistors for the P-side power supply

- integrated under-voltage protection

- extended over-temperature protection with additional LVIC temperature monitoring

- integrated short-circuit and over-current protection

| Product Name | Ratings | Switching speed |

|

|

18.8 mm x 32.8 mm |

SLIMDIP-S | 5 A, 600 V | Fast |

|

SLIMDIP-M |

10 A, 600 V | Fast | |

| SLIMDIP-L | 15 A, 600 V | Regular | |

| SLIMDIP-W | 15 A, 600 V | Fast | |

|

Under development |

Higher current ratings |

Table 1: Line-up of SLIMDIP™ IPM product group

For a better performance understanding of each device, the diagram in figure 1 shows the simulated output current versus switching frequency.

Figure 1: SLIMDIP™ products output current simulation results

The SLIMDIP™ products use the 2nd Gen. reverse conducting IGBT chips (RC-IGBTs). With this technology, a further significant step towards high integration with more compact and more straightforward solutions can be achieved.

RC-IGBT Power Chip used in SLIMDIP™ IPM

Both structures, IGBT and free-wheeling diode are integrated into one chip in an RC-IGBT chip. Especially for small current devices, it contributes remarkably to the package downsizing and system cost reduction. The wire bond layout is easier to realize than the conventional solution with separate IGBT and diode [2].

The particular difficulty with the RC-IGBT is that it is challenging to optimize the balance between IGBT and diode performance. For this, Mitsubishi Electric investigated different design concepts to improve the reverse recovery characteristics of diode and total RC-IGBT chip performance. Based on this study, the second generation of the RCIGBT was released.

Mitsubishi Electric uses the 2nd Gen. RC-IGBT in SLIMDIP™ products. The 2nd Gen. RC-IGBT structure is shown schematically in figure 3 below.

The diode VEC vs. ERR trade-off relationship was improved by approximately 52 % in the second generation of RC-IGBT chip without decreasing the IGBT performance. This improvement was achieved especially by advanced thin wafer technology and optimized diode IGBT layout on the chip with properly selected diode structure and diode ratio.

Figure 2: 2nd Gen. RC-IGBT chip structure

Integrated Over-Temperature Protection

An essential feature of the SLIMDIP™ family is comprehensive temperature monitoring. In addition to the hardware-implemented overtemperature shutdown (OT) function, it is possible to continuously monitor the temperature during operation (VOT) and react accordingly before the hardware shutdown occurs.

The excess temperature shutdown is at 130 °C typically. As soon as this temperature is reached at the LVIC, the IPM switches off its gate outputs and reports an excess temperature error to the microcontroller.

With additional analog temperature monitoring on the LVIC, irregularities in the cooling, such as fan defects or heavy pollution, can be determined at an early stage. The IPM user has different options to utilize the temperature monitoring function (VOT). There is a possibility to output an error message or change the control scheme before the IPM reaches the over-temperature trip level and switches the gates off.

IPM Power Supply Integrity

Another beneficial feature of the SLIMDIP™ family is the utilization of high voltage IC (HVIC) with the required components like a bootstrap diode (BSD) and current limiting resistors. The standard three-phase inverter requires four isolated power supplies; three for P-Side and one for N-Side. Integrated into the SLIMDIP™ HVIC circuit allows reducing the number of power supplies from four to one. [3] The usual external functional isolation of P-Side switches is not required. This functional isolation is provided inside of HVIC via level shifting.

Figure 3 shows the principle diagram schematically for a bootstrap circuit.

Figure 3: Bootstrap circuit

The SLIMDIP™ LVIC has to be supplied with a sufficient power supply voltage of 15 V. This voltage secures the proper functionality of the N-side switches and charging of the P-Side. When the output (U, V, W) potential goes down to the GND level, the current flows through the bootstrap diode and charges the bootstrap capacitor. When output (U, V, W) voltage returns to VCC, the bootstrap capacitor's low side remains connected to the emitter of the P-Side switch.

The capacitor discharges its energy driving the P-Side switch's gate to a voltage sufficient to turn it on, while the bootstrap diode blocks that voltage from leaking back.

All SLIMDIP™ power modules are equipped with HVIC, bootstrap diodes and with in-rush current limited resistances. The built-in components reduce the assembly cost and system FIT rates during operation.

Short Circuit Protection Function

A further feature in SLIMDIP™ is detecting short circuit SC current and stopping the operation of IPM. SLIMDIP™ uses an external shunt resistor for the short current detection, as pictured in figure 4. The protection circuit is realized in the LVIC. The voltage over shunt resistance is compared with reference SC trip voltage inside LVIC to detect high short circuit current. The threshold voltage trip level is typically 0.48 V. The exceeding of reference trip voltage would automatically trigger protection function. All gate signals of bottom switches would be interrupted, and a fault output signal would be generated. The external RC filter is to be used to avoid activation of protection by normal switching noise. A time constant of about two μs recommended being used for the RC filter. Additionally, it is recommended to use shunt resistance and pattern wiring with low effective inductance to prevent error fault output.

Conclusion

SLIMDIP™ products become the worldwide standard solution for power electronic systems with requirements on a high degree of integration, performance and reliability. The power module SLIMDIP-M with 10 A and 600 V rating was developed to expand the product lineup. The development of the SLIMDIP™ IPM with even higher power density is already started to cover the future demand and continue the SLIMDIP™ product family's success.

Figure 4: Short circuit detection principle for SLIMDIP™ IPM

References

[1] S. Shibata, M. Kato and H. Zhang, "New Transfer-Molded SLIMDIP for white goods using thin RC-IGBT with a CSTBTTM structure," Proceedings of PCIM Europe 2015; International Exhibition and Conference for Power Electronics, Intelligent Motion, Renewable Energy and Energy Management, Nuremberg, Germany, 2015, pp. 1-6.

[2] T. Yoshida, T. Takahashi, K. Suzuki, and M. Tarutani, “The second-generation 600V RC-IGBT with optimized FWD,” in 2016 28th International Symposium on Power Semiconductor Devices and ICs (ISPSD), Prague, Czech Republic, 62016, pp. 159–162.

[3] Mitsubishi Electric, Bootstrap Circuit Design Manual. [Online]. Available: https://www.mitsubishielectric.com/semiconductors/ files/manuals/dipipm_bootstrap_circuit_ e.pdf (accessed: Feb. 2021).

This article originally appeared in Bodo’s Power Systems magazine.

About the Author

Eugen Stumpf works as the Application Engineering Manager at Mitsubishi Electric Europe B.V, a wholly-owned subsidiary of Mitsubishi Electric Corporation, headquartered in Tokyo, Japan. He earned his Engineering Diploma in Power and Energy at FHD University of Applied Sciences Dusseldorf. He also earned his Master of Business Administration (MBA) at FOM University of Applied Sciences for Economics and Management.

Eugen Wiesner is an Application Engineer at Mitsubishi Electric Europe B.V., Ratingen Germany, one of the branches of the Japanese multinational electronics and electrical equipment company, Mitsubishi Electric Corporation. He earned his Master's of Science in Electrical Engineering at the University of Applied Sciences Dusseldorf located in Germany.

Akiko Goto works at Power Device Works division at Mitsubishi Electric Corporation located in Fukuoka Japan.