Romeo Power Closes $30 Million Seed Financing; Ramps Battery Pack Production

Romeo Power, the energy storage technology company founded by top engineers and designers from SpaceX, Tesla, Apple, Amazon and Samsung, today announced $30 million in seed financing. The announcement comes as Romeo Power finalizes the installation of a fully automated 113,000 square foot manufacturing facility near downtown Los Angeles, and ramps production of its lithium-ion battery packs for electric vehicle (EV) and stationary storage applications.

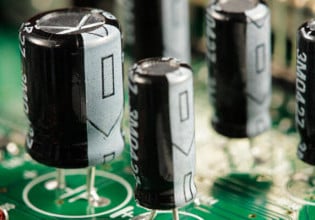

Romeo Power’s modular battery packs – comprised of cylindrical lithium-ion cells – can be used in cars, power sport vehicles, motorcycles, trucks, buses, and forklifts. Using the same advanced battery pack design, the company’s stationary energy storage for businesses, PowerStack™, harvests and stores electricity from the grid during off-peak hours for energy arbitrage, cost savings and use during peak times or outages.

Since Romeo Power kicked off sales in 2017, the company has seen $65 million in initial orders scheduled for delivery in 2018. Current contracts and design agreements for the company span U.S. and European automakers, manufacturers of motorcycles and forklifts, industrial players such as Power Designers, robotics companies including Robotic Assistance Devices, and more.

Michael Patterson, Romeo Power founder, and CEO

Michael Patterson, Romeo Power founder, and CEO

“We’ve seen incredible momentum in a short period, and we’re scaling manufacturing as fast as we can to meet demand,” said Michael Patterson, Romeo Power founder, and CEO. “There’s a massive market opportunity for energy storage technologies.”

The EV market alone is expected to reach $32 billion by 2020. And recent government mandates around the world to eliminate gas cars are accelerating demand for advanced lithium-ion battery packs that can deliver more energy, range, faster charge times, smaller footprints and exceed current safety standards.

“Romeo Power’s pack technology platform delivers on all of these requirements better than any other battery pack available today,” said Patterson.

The Romeo Power Technology Platform

Romeo Power’s team of engineers is led by company Co-founder and Chief Technology Officer Porter Harris, who developed the battery technology powering SpaceX’s F9 rocket and Dragon spacecraft. Building on technologies developed for aerospace, Harris and his team has created a technology platform that exceeds performance in three core areas:

- Highest Energy Density: The Romeo Power technology offers the highest energy density by 25 percent, providing dramatically increased range.

- Fastest Charge Times: With the highest thermal performance, the technology is optimized for the fastest charge times, decreasing standard battery charge times by 15 percent to 30 percent.

- Superior Safety: All designs are built with inherent thermal runaway mitigation and feature multiple fault-tolerant software and hardware to protect against cross cell propagation.

Co-founder and Chief Technology Officer Porter Harris,

Co-founder and Chief Technology Officer Porter Harris,

“We’ve applied technologies developed for applications in space and aerospace, and we’ve improved upon them to create products that break new ground for EVs and stationary energy storage,” said Harris.

All Romeo Power products include an advanced battery management system based on control-oriented, physico-chemical models. Combined with the company’s innovations in thermal engineering, manufacturing processes, and materials, Romeo Power products have smaller space requirements than any other batteries on the market and offer enhanced state-of-charge (SOC) and state-of-health (SOH) monitoring.

State-of-the-Art Manufacturing Facility

The company’s fully automated 113,000 square-foot manufacturing facility is on track to be complete by the end of the year. Romeo Power designs, engineers, test, and produce all of its lithium-ion battery packs on-site, and the facility features the only research and development and testing lab on the West Coast. The battery packs are designed and optimized based on specific power and energy density needs, ranging in size from 1kWh to 1MWh. Romeo Power will be at 1GWh of capacity on a single shift by the end of 2017 and will quadruple its capacity in 2018 to 4GWh per shift.

Li-ion Battery Packs

Last month, Romeo Power introduced THUNDER PACK™- C, the first lithium-ion (Li-ion) battery pack designed to be adapted for any electric forklift make or model. Like its predecessor, the THUNDER PACK - J 2.0, THUNDER PACK - C is safer, non-toxic and far more energy efficient with significantly longer cycle life than lead acid batteries that still dominate the global forklift market, now forecast to reach $55.9 billion in 2021.

Romeo Power THUNDER PACKs are warranty-backed to last 4,000 cycles – approximately 12 years – deliver quick recharge, require no maintenance, and produce zero emissions and zero odors. In contrast, traditional lead-acid forklift battery packs have much shorter cycle life, long recharge and cool-down periods, need constant maintenance, run out of energy in as few as six hours, and emit hydrogen sulfide gas and sulfuric acid that smells bad, is messy, and hurts the environment.

“In our experience forklift buyers want three things: more safety, longer drive time and less downtime,” said Patterson. “THUNDER PACK – J 2.0 – and come December, THUNDER PAC – C – were developed to deliver on all three criteria better than any other battery pack on the market today.”

All Romeo Power battery packs are engineered to exceed the most stringent government safety requirements and include an advanced battery management system based on control-oriented, hysicochemical models. Combined with the company’s innovations in thermal engineering, manufacturing processes and the materials chosen to connect components, Romeo Power battery packs have smaller space requirements than other battery packs on the market and offer enhanced state-of-charge (SOC) and state-of-health (SOH) monitoring.

“Romeo Power battery packs are just unbeatable,” said Dan Crowley, CEO of Madison, WI-based Power Designers USA, an innovative battery charger company that provides battery packs and charging solutions for forklifts and other materials handling equipment. “THUNDER PACK’s design, materials and thermals, combined with Power Designers’ advanced charging algorithm are totally winning the day with our customers – especially big, name-brand packaged goods and food companies with massive fleets of forklifts in their warehouses.”