Protean Partners with SKF to Develop Advanced Drives for Hybrid and Electric Vehicles

Protean Electric, Inc. today announced a strategic partnership with SKF Group to provide critical components for Protean's in-wheel electric drive system. The two companies also will look at additional new areas of collaboration for the hybrid and electric vehicle market.

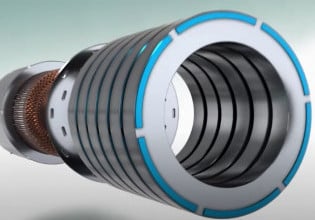

The Protean-SKF five-year strategic partnership agreement will initially focus on the unique wheel bearing system with integrated sealing and sensors developed by SKF specifically for Protean Electric. The bearing design has a significant influence on the performance of the in-wheel motor, which operates in an extremely harsh environment. The Protean bearing is custom-designed, in anticipation of a new market segment for wheel motors. Beyond this initial project the companies will both look for new areas of collaboration that capitalize on their core expertise.

"We believe our in-wheel electric drive system will enable the wide-spread transformation of the global auto industry, and we are very pleased to partner with SKF, which is also a leader in its field," said Protean Electric Chairman and CEO Bob Purcell. "Only SKF can supply a bearing to meet the requirements for our unique in-wheel electric drive system. SKF also has the competence and skills to support the entire development lifecycle and series production."

"Aligned with our BeyondZero strategy, SKF is committed to developing technology to support the electric and hybrid vehicle market to further reduce the carbon footprint. Combining our engineering knowledge with Protean's expertise for in-wheel motors will be an excellent way to develop this market," said Tryggve Sthen, president, SKF Automotive.

Protean's in-wheel electric drive system is at the forefront of the next generation of technology to power motor vehicles. The electric motors reside in the unoccupied space in the wheel, producing power or propulsion exactly where drivers need it. Protean Drive™ is a flexible system that can be used in pure electric vehicles, fuel cell vehicles or hybrid applications. The system also can be retrofitted to vehicles currently on the road with minimal modifications and installation. Production is scheduled to begin in 2013 in Liyang China.

Protean's in-wheel solution provides: Fuel economy improvements across a wide range of vehicles of up to 30 percent depending on battery size; 8kW (110hp) and 800Nm (590lb.-ft. torque) in each motor; Powerful enough for hybrid, PHEV or used as the only source of traction drive for EV applications; Highest torque density of any of today's leading electric propulsion systems; Weight of only 31 kg (68 lbs.) per motor; Fits within the space of a conventional 18-inch road wheel, simplifying vehicle integration; Superior regenerative braking capabilities, which allow up to 85 percent of the available kinetic energy to be recovered during braking.