Nano Dimension Ltd. announced that its technology, DragonFly LDM system and materials were used by Piezoskin S.R.L. to develop a 3D printed sealed packaging with electrical pads for Micro-Electromechanical Systems (MEMS).

The printed electronics package has the electrical pads directly printed on the metal layers on which an RF connector is soldered. The ability to transfer electric pads in a sealed package is one of the most crucial parts in ohmic-contact microelectromechanical systems (MEMS) as it determines the device performance and reliability, particularly for soft and flexible devices where the electrical connectors are typically difficult to produce.

"Nano Dimension's AME technology helped us to achieve an original product prototype in which wires and connectors were eliminated such that the package was minimized to obtain an optimal user experience. It simplifies the manufacturing process compared to traditional manufacturing methods," said Dr. Francesco Guido, CTO of Piezoskin S.R.L.

"With the DragonFly LDM 3D printer, Piezoskin can design customized printed packages with flexible transducers, to meet their customers unique needs, drive innovation and get products to market faster," said Mr. Yoav Stern, Nano Dimension's CEO and President.

Piezoskin

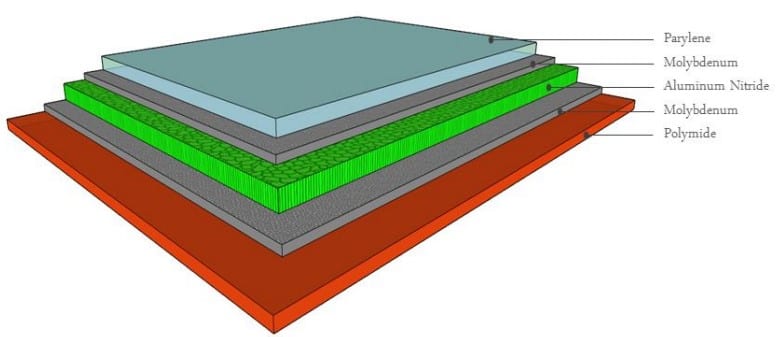

The Piezoskin team has developed a consolidated fabrication protocol of flexible piezoelectric nanogenerators and sensors. The devices are based on a polymeric substrate and a highly flexible thin films structure (thanks to an optimized reactive sputtering deposition), composed of Aluminum Nitride, as piezoelectric layer, and Molybdenum as electrode. The extremely low thickness of the whole structure (below 30µm) makes the product the thinnest piezoelectric transducer in the market.

Schematic representation of the multi-layered structure of Piezoskin products

Schematic representation of the multi-layered structure of Piezoskin products