High-Voltage SiC Power Modules Improve EV Charging, Storage Efficiency

SemiQ’s high-performance silicon carbide power modules are rated to 1200 V and offer high efficiency and power density for energy storage, EV charging, and solar inverter applications.

SemiQ has expanded its QSiC series of half-bridge, silicon carbide (SiC) high-voltage power modules. The modules are constructed with the company’s latest high-voltage SiC MOSFET technologies to minimize dynamic and static losses in power-dense applications.

Device burn-in testing. Image used courtesy of Micross

The modules are designed for a range of applications, including electric vehicle (EV) charging, onboard chargers (OBCs), DC-DC converters, medical power supplies, photovoltaic inverters, and energy storage systems.

Along with a high breakdown voltage, the modules feature ultra-low on-resistances that reduce conduction losses and a high operating temperature that supports compact and dense system designs.

QSiC Power Modules

The QSiC series of power modules are fully tested and available in industry-standard packaging for half-bridge circuits. Each module is rated for high-voltage operation up to 1200 V with a breakdown voltage that exceeds 1400 V.

QSiC power module. Image used courtesy of SemiQ

The product extension consists of four models that feature ultra-low SiC MOSFET on-resistances of 5 mΩ, ten mΩ, and 20 mΩ and are rated for continuous current levels as high as 383 A. Combined with a maximum operating junction temperature (TJ) of 175°C, these performance parameters support the most power-dense designs.

QSiC series extension models. Image used courtesy of SemiQ

Extensive burn-in and stress testing of each module reduces failure rates while improving performance and long-term reliability. In addition, all modules have extended short-circuit ratings and undergo testing above 1350 V.

Device Burn-In for Gate Stability

A common design challenge with wide bandgap technologies, like SiC, is developing reliable gate drive circuits to control the FETs. To help with this challenge, each FET within the QSiC module undergoes gate burn-in testing at the wafer level.

For power devices, modules, and other electronics, burn-in is a form of accelerated life testing that involves operating the unit at power for a specified time to screen out weaker units or units that can’t meet operational specifications.

For the QSiC modules, the gate burn-in testing ensures that each production unit has a stable gate threshold voltage with high-quality gate oxide. The uniformity of these parameters across devices relaxes gate drive design requirements while improving manufacturability and production yields.

Half Bridge Modules for EV Charging

Most residential EV chargers are Level 1 chargers that generate single-phase AC power to charge an EV from a standard 120 V outlet.

Since batteries power EVs through DC power buses, the AC power from the charger needs to be converted to high-voltage DC (400 V or higher) to replenish the lithium-ion battery pack.

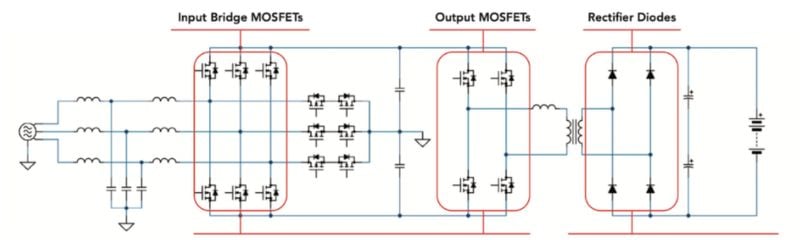

The onboard charger is the functional circuit block within the EV that handles the conversion of charge power from AC to DC. For Level 1 and Level 2 charging, the OBC is typically composed of an input PFC and rectification circuit, followed by a transformer-isolated DC-DC converter that steps up the output to the high voltage of the battery bus.

Half-bridge circuits, like the QSiC modules, are used throughout the various power conversion stages of the OBC.

EV charging using bridge circuits. Image used courtesy of SemiQ

For public access DC fast charging applications, bridge circuits are used to convert three-phase AC line power to high-voltage DC that can be used to charge the EV battery directly, bypassing the OBC. Bypassing the OBC allows for much higher charge power levels (300 kW or more), resulting in charge times of well less than one hour for most EV battery packs.