ABB, CERN Identify Energy-Efficient Electric Motor Designs

ABB-CERN partnership unveils energy-saving potential equating to 18,000 European homes through an ABB energy efficiency audit.

Conserving electricity has become part of a global effort toward the energy transition. Saving electricity lowers utility bills and represents a commitment to minimizing the carbon footprint. However, outdated infrastructure and insufficient awareness about energy-saving practices are major challenges encompassing energy efficiency.

Joint research from ABB and CERN identified substantial energy-saving opportunities in cooling and ventilation systems. This article looks at energy consumption in electric motors and the findings of the research.

A glimpse of CERN’s large-scale ventilation facility. Image courtesy of ABB

The Role of Electric Motors

Electric motors are a ubiquitous component in modern daily life and industry. In household appliances, motors find use in common household appliances and HVAC systems. Similarly, in industry, motors drive heavy machinery, manufacturing processes, heating systems, ventilation systems, and transportation systems, enabling the production of goods and the facilitation of logistics on a massive scale. Given the ubiquity of electric motors, improving the efficiency of these devices could have a profound impact on global energy demand.

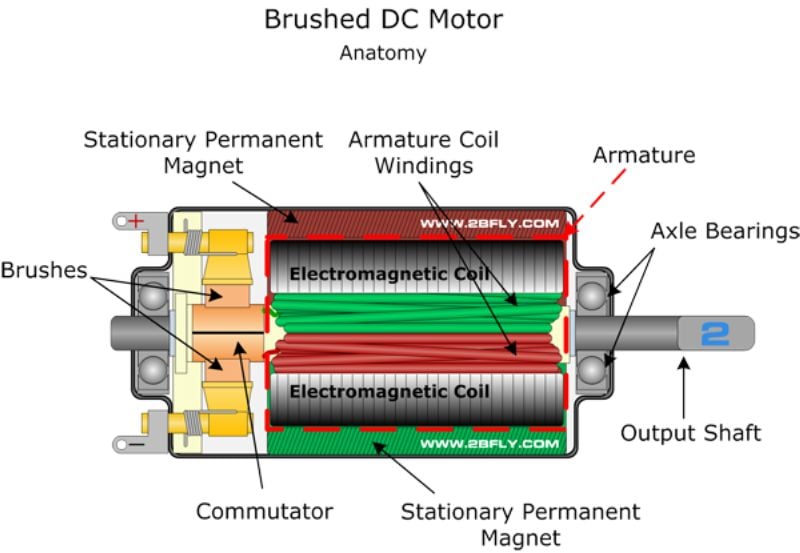

An electric motor uses the interaction of magnetic and electric fields, governed by Ampere’s law, to convert electrical energy into mechanical motion. This principle involves passing current through a closed loop, inducing a magnetic field, and creating attraction between the loop and the resulting magnet. This attraction causes rotation, driving the motor's functionality.

The anatomy of an electric motor. Image courtesy of International Journal of Recent Technology and Engineering

Electrical inefficiency in motors arises from resistive losses in windings due to copper conductivity, core losses from hysteresis and eddy currents, mechanical friction, and inefficient control mechanisms such as voltage drops and harmonics. Resistive losses stem from wire properties and current levels, while core losses result from magnetic realignment and eddy currents. Friction occurs at moving parts, and windage loss arises from air resistance. Mitigating inefficiency requires optimizing motor design, adopting predictive maintenance, and addressing control system inefficiencies.

ABB and CERN

ABB and CERN recently joined forces to combat energy inefficiency in heating and ventilation motors used at a major particle physics laboratory in Geneva, Switzerland. This facility encompasses motors powering various equipment such as pumps, fans, compressors, and cooling towers, constituting approximately 20% of CERN's total energy usage.

The groups engaged in an extensive energy audit targeted at understanding and upgrading 800 motors in the facility. As part of this effort, the group integrated data from diverse sources, comprising digitally connected motors, CERN's SCADA system, and direct data acquisition from pumps, piping, and instrumentation. They found that the overdesigning of motors is very common for heating and ventilation systems, with specified maximum loads often far exceeding average usage. For example, one pump motor at CERN displayed a notable 64% energy-saving potential due to overdesign.

Utilizing data-driven insights, including SCADA system integration, the team identified impactful upgrades such as IE5-rated Synchronous Reluctance Motors with variable speed drives.

CERN facility. Image used courtesy of ABB

As a result, the audit unveiled a 17.4 percent savings opportunity, with a projected payback time of less than two years. Specifically, the research uncovered the potential for annual energy savings of up to 31 gigawatt-hours (GWh), which, if realized, could prevent four kilotons of CO2 emissions, equivalent to planting over 420,000 trees.

The ABB-CERN Audit

The audit from ABB and CERN is important because it identifies and directly targets a major source of energy inefficiency. Since motors are commonplace in industrial and residential buildings, similar energy savings are likely attainable elsewhere.