Converting Gas Turbine Fleets for Ammonia Combustion

GE Vernova and IHI Corporation will develop a two-stage gas turbine combustion system that generates power with 100% liquid ammonia.

Japanese manufacturer IHI Corporation plans to transform GE Vernova’s natural gas-fueled turbines to run on liquid ammonia. Over the next two years, IHI will scale up a two-stage combustion system for GE’s worldwide F-class heavy-duty turbine fleet, providing a flexible and carbon-free alternative to burning fossil fuels in power generation, steel and petrochemical production, and other high-polluting sectors.

The two-stage combustor will be configured to burn up to 100% ammonia while complying with emissions requirements. IHI and GE Verona will now explore combustion concepts that meet power plants’ operational demands.

The project will retrofit GE Vernova’s 6F.03, 7F, and 9F turbines with a two-stage combustion system supporting ammonia.

IHI’s 2 MW gas turbine. Image used courtesy of IHI Corporation

Why Ammonia?

Ammonia can be used as a fertilizer, refrigerant, or chemical raw material for plastic production. As a hydrogen derivative, it often serves as an energy carrier and storage method for shipping hydrogen overseas to industrial hubs. Unlike hydrogen, ammonia enables the safe transport of large amounts of energy in less space and over longer distances.

9F gas turbine. Image used courtesy of GE Vernova

Making carbon-free ammonia requires hydrogen produced via electrolysis with 100% renewable resources—like electricity from solar or wind farms—and combined with nitrogen extracted from the air. The resulting ammonia can be transported by ship to ports and logistics destinations. After it arrives, it’s split back into hydrogen and nitrogen through an ammonia cracking process.

When used for electricity generation or as a fuel source, ammonia’s only byproducts are nitrogen and water. Since it emits no carbon dioxide (CO2) when burned, it continues to gain global popularity as an alternative fuel source in natural gas power generation.

Ammonia for Power Generation

Existing power generation facilities can use ammonia as a clean-burning fuel free of CO2 emissions upon combustion. IHI’s method directly sprays liquid ammonia into the gas turbine combustor. This simplifies the liquid ammonia fuel supply system from the storage tank to the turbine and allows for more controllability. It’s easier to transfer storage tanks in gas turbines that burn liquid ammonia directly into combustors.

Still, there are technical challenges. Liquid ammonia is less flammable than gaseous ammonia and natural gas, making it harder to burn. Achieving high co-combustion ratios of liquid ammonia requires stabilizing flames in combustion and suppressing greenhouse gases in the exhaust stream.

Operating a gas turbine at an ammonia co-firing rate exceeding 70% could cause nitrous oxide to form, which negates the reduction in CO2 emissions. Even when burning ammonia produced from carbon-free sources, nitrous oxide emissions could still be high.

IHI’s Two-Stage Combustion Solution

IHI has been experimenting with combusting ammonia in a 2 MW IM270 gas turbine for two years. Its co-generation approach produces electricity with a fuel-burning gas turbine and recovers steam or other energy from waste heat.

IHI achieved a significant milestone in mid-2022 when its system generated power by combusting 100% liquid ammonia, demonstrating a more than 99% reduction in greenhouse gas emissions. Nitrous oxide output was also minimized.

This result was replicated when using the combustor on a turbine with an ammonia fuel ratio of 70-100%. IHI verified the 2 MW output when mono-firing liquid ammonia.

The results of IHI’s ammonia combustor system testing in 2022. Image used courtesy of IHI Corporation

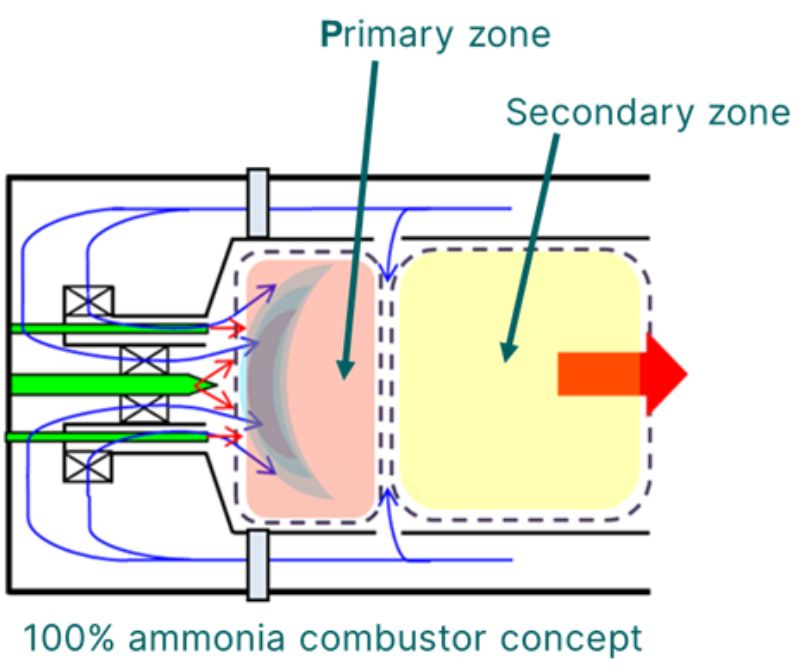

Retrofitting GE Vernova’s F-class turbines to burn ammonia requires a two-stage system using a rich-lean combustion method. Per the National Energy Technology Laboratory, this process generally starts with a “rich” phase that converts part of the ammonia to hydrogen gas via oxidation while limiting the availability of oxygen to form nitrous oxide. The secondary “lean” stage injects air into the combustor to quench the rich flame and burn the remaining ammonia and hydrogen gas.

A two-stage combustion system fueled by ammonia. Image used courtesy of GE Vernova

IHI plans to scale its combustor technology before bringing ammonia-dedicated gas turbines to market by 2025.