Novel Natural Gas Plant Design Attains Over 99% Carbon Capture

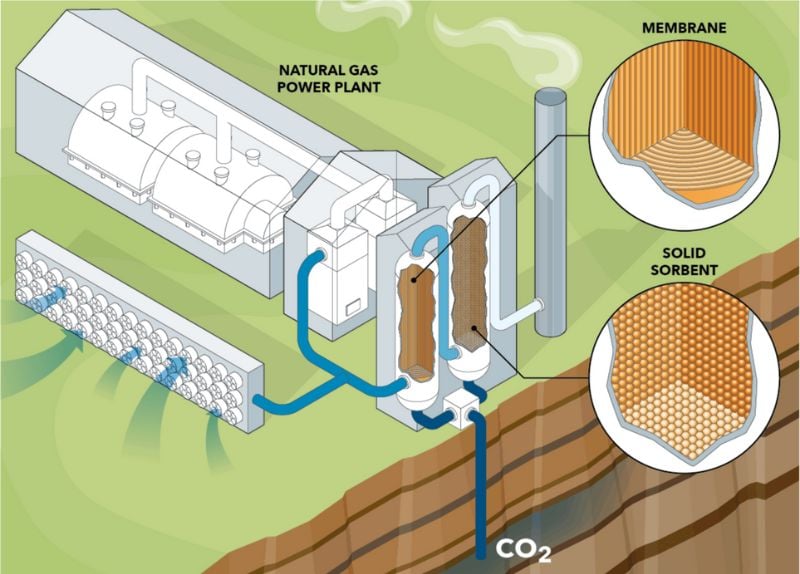

Researchers achieved near net-zero emissions from a hybrid membrane solid sorbent carbon capture system for natural gas plants. Here’s how the system curbs emissions.

Natural gas-fired combined cycle (NGCC) power plants are popular for their efficiency, but natural gas generation emits high levels of carbon dioxide (CO2). To address this problem, University of Pittsburgh researchers developed a hybrid carbon capture system for NGCC plants that can capture more than 98% of carbon dioxide during peak- and off-peak operations.

Natural gas combined cycle plant. Image used courtesy of Wikimedia Commons

The model system, which can be retrofitted for existing NGCC plants, integrated a solid sorbent material downstream of a membrane system. The membrane is the primary point-source capture system, while a sorbent counterpart captures CO2 from the air and membrane exhaust. The combined solution is adaptable to changing grid conditions.

NGCC Plants: Design, Efficiency, Emissions

In conventional simple-cycle combustion turbine plants, hot gas generates electricity through a turbine. Newer combined-cycle systems use simple-cycle turbines, heat recovery, and steam turbine generators for improved efficiency and dispatch times. NGCC plants typically have a higher capacity factor than simple-cycle systems, supplying base and intermediate loads to the grid. NGCC systems combining steam and combustion turbines represent more than half of U.S. natural gas-fired generating capacity, according to the U.S. Energy Information Administration.

Since gas power plants can turn on and off quickly, they’re ideal for responding to seasonal and short-term demand spikes. In the transition to renewables, natural gas plants serve a critical role as dispatchable resources to counter intermittent solar and wind generation. NGCC plants operate efficiently at a partial load, ensuring electricity generation stays stable as more variable resources join the grid. This pivotal role as a transition fuel keeps natural gas relevant in the electricity mix, while coal’s share has steadily declined. Natural gas represents about 40% of electricity generation in the U.S. and more than 20% globally.

NGCC plants still have a significant carbon footprint, even though combustion in the gas turbine produces less emissions than coal-fired power plants. Plants have installed various carbon capture and storage (CCS) technologies with high capture rates to mitigate emissions. For example, some use post-combustion capture systems to pull CO2 from the flue gas via a solvent.

The proposed design by the University of Pittsburgh researchers boasts high capture rates and easy cycling between load conditions—meeting two vital requirements for successful CO2 capture technologies at NGCC plants.

Researchers developed a novel hybrid membrane + solid sorbent system design for NGCC plants. Image used courtesy of the University of Pittsburgh

Introducing a Hybrid Carbon Capture System

First, the natural gas exhaust is processed by a membrane CCS system and then by a solid sorbent material. The researchers integrated the models into one optimization platform to achieve the highest net present value and capture rate.

Optimized results for a natural gas power plant using the hybrid membrane and solid sorbent system design. Image used courtesy of the study’s authors (Creative Commons) -- graphical abstract

In selecting adsorbers, the researchers opted for solid sorbents rather than aqueous solvents, as the former can accommodate low CO2 concentration capture with less energy and operating costs. Their solid sorbent would need to capture CO2 under conditions ranging from unpressurized air with 400 parts per million (ppm) of CO2 to NGCC exhaust with about 40,000 ppm of CO2.

For the solid sorbent system, the researchers selected a tetraamine-appended metal-organic framework (MOF) material developed by University of California–Berkeley researchers who demonstrated the MOF for CO2 partial pressures from 400 ppm to 50,000 ppm. The material offers stable and high adsorption capacity under humid conditions and a 90% capture rate when used on post-combustion natural gas exhaust. It’s also capable of adsorption at high temperatures, with a smaller temperature swing between adsorption and desorption, thus reducing operating costs. It can be regenerated using low-temperature steam, making it ideal for an NGCC plant.

When combined with a membrane, the integrated system provides high carbon capture rates and additional flexibility to grid dynamics. Membranes are well-suited for variable electric grids because they respond quickly. Carbon capture membranes can also recover CO2 at high purity with little energy. However, since these systems may struggle to attain high CO2 capture rates independently, the researchers selected a fast-responding solid sorbent-based technology to offset the CO2 from the membrane process.

How Does the Integrated System Work Together?

In developing the solid sorbent system, the researchers modeled fixed bed adsorbers containing MOF solid sorbents that adsorb CO2. Using steam from the plant, the sorbents then perform temperature swing desorption. The MOF bed adsorber design alone can offer 86.6% carbon capture during peak operation and 85.4% off-peak. Combining it with the membrane system boosts the capture rate to over 98%.

The top two charts compare the system’s power output and efficiency performance in Modes 1 and 2. The bottom chart shows the capture rates for each component. Image used courtesy of the study’s authors (Creative Commons) -- Figures 9 (top) and 10 (bottom)

The membrane captures CO2 from the NGCC exhaust gas, while the solid sorbent removes CO2 from the membrane system under Mode 1 operations with high load conditions. In Mode 2 (low load conditions), the solid sorbent draws CO2 from the membrane system exhaust and the compressed air (via the surroundings and NGCC compressor). The system offers a 99.3% carbon capture rate from the inlet natural gas stream during high electricity demand and 99.6% during low demand conditions.

Compared to a baseline NGCC system without carbon capture, the novel system offers a higher net present value. This means its performance is more profitable than operating without it in a future scenario that assumes CO2 taxes of $100 per tonne are imposed. Also, the proposed system captures more carbon with less emissions than an alternative CCS system using an amine solvent with a 90.7% capture rate.

The researchers mentioned that net-negative emissions could be achieved in future projects by selecting a solid sorbent better suited to DAC conditions, enabling more air to be processed.