Trenchless Distribution Tech Speeds Line Undergrounding

Federal funding supports trenchless technologies designed to hasten the construction and installation of electric power distribution lines.

Weather damage and tree-related incidents account for most power outages in the United States today. Utilities can mitigate these failures by placing distribution lines underground. However, existing construction methods are often costly and time-consuming.

Utilities are always looking for ways to speed up the process. That’s the focus of an Arizona State University (ASU) project that recently secured a three-year, $4.26 million grant from the Department of Energy (DOE) to develop a water-jet undergrounding tool that buries medium-voltage electrical distribution lines with a single pass system.

A roadside utility work sign from Green Mountain Power. Image used courtesy of Green Mountain Power

This trenchless approach will allow utilities to underground electrical cables and conduits with a quicker construction turnaround for reaming and duct pulling tasks. It eliminates the hard drill bit used in conventional trenchless installation processes like horizontal directional drilling (HDD), which involves establishing a borehole and pulling a conduit before running the distribution lines.

ASU’s technology installs conduits simultaneously during the excavation process, anticipating an up to 50% reduction in construction times and costs. The funding was awarded through the $34 million GOPHURRS (Grid Overhaul with Proactive, High-speed Undergrounding for Reliability, Resilience, and Security) program, administered by the DOE’s Advanced Research Projects Agency-Energy (ARPA-E).

The program targets concurrent drilling and conduit installation methods minimizing inefficiencies in existing medium-voltage (5 to 46 kV) distribution grid construction procedures.

Placing Cables and Conduits Underground Simultaneously

ASU’s trenchless project uses excavation and spoil removal systems to prevent ground fracturing and damage to nearby facilities and structures. Utilities need to understand the impact of ground behavior during excavation and how to control any problems arising in installation.

ASU’s technology passes high-pressure water through a steering drill head to create a borehole. Then, it clears the path for excavation by vacuuming the slurry back out of the borehole. The system was developed with Vermeer Corp., an Iowa-based underground utility equipment manufacturer, and Brierley Associates, a Colorado consultancy specializing in underground infrastructure.

In addition to lowering installation costs, ASU’s approach improves security by reducing tower components, making the system inaccessible above ground. This benefit is also critical for preventing physical attacks on electrical infrastructure, which have increased over the last few years.

The trenchless technology builds on ASU’s existing work developing HDD methods to install conduits for solar farms and offshore and onshore wind projects.

Underground Lines Improve Grid Reliability

ASU is one of 12 projects receiving $34 million to advance high-speed undergrounding construction technologies supporting a more reliable and secure power grid. According to the National Academy of Engineering, the U.S. power distribution system comprises more than 5.5 million line-miles with 180 million poles. This infrastructure is vulnerable to weather- and tree-related incidents, which contribute to over half of the country’s annual outages. More than 90% of power line failures occur at the medium-voltage distribution level.

The GOPHURRS funding comes as undergrounding activities have amassed mainstream adoption as more utilities move away from overhead electric distribution infrastructure. Costs have declined in recent years, partly because the federal government has stepped in to cover a portion of much-needed grid investments. The Bipartisan Infrastructure Law (signed in 2021) and Inflation Reduction Act (2022) have allocated billions of dollars for infrastructure upgrades.

In addition to securing lines from severe weather damage, undergrounding creates other benefits across the lifecycle, such as extending the service life of underground cables and saving on pole inspections and vegetation management.

Several major utilities have incorporated undergrounding activities into their ongoing system-hardening plans. California’s PG&E, for example, is undergrounding hundreds of miles of power lines each year, targeting 2,300 miles by 2026. Georgia Power’s Grid Investment Program has installed more than 345 miles of underground lines. And, Vermont’s leading utility is spending $250 million to underground and storm-harden its lines.

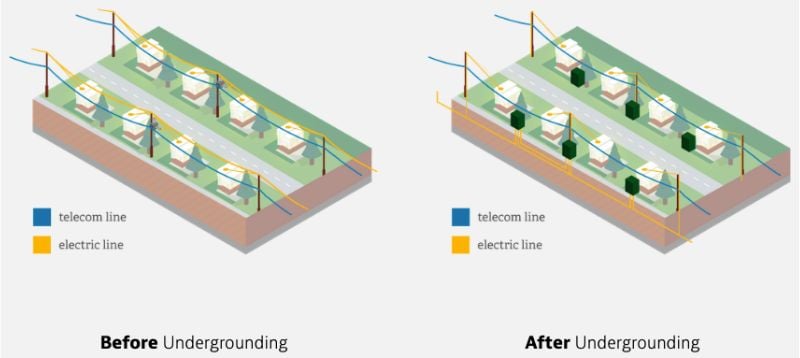

Before and after moving overhead utility lines underground. Image used courtesy of Georgia Power

DOE Advances Distribution Undergrounding Tech

The dozen GOPHURRS awardees include businesses, national labs, and universities across 11 states. ASU was one of three recipients receiving more than $4 million.

Other projects securing the highest awards include the RTX Technology Research Center in Connecticut, which will develop a radar-based mobile sensor platform that uses quantum radio frequency sensing and artificial intelligence to locate existing utility lines before installing new ones underground. The technique is expected to improve 3D subsurface reconstruction accuracy by 95% compared to conventional data processing methods.

Prysmian Cables and Systems USA in Kentucky received $4.5 million to develop a hands-free power cable splicing machine for underground vaults. The system can lower splicing-induced medium-voltage network failures to less than 5%, compared to 60-80% with existing methods.

While GOPHURRS projects focus on power distribution, the results don’t just apply to the energy sector. Trenchless technologies can be useful in installing other infrastructure affected by severe weather, such as fiber optic cables and natural gas distribution systems.