LG Chem To Build North America’s Largest Cathode Plant

LG Chem’s Tennessee plant will have an annual capacity of 60,000 tons of NCMA cathode materials. This article explores NCMA cathodes, their benefits, and the details of the plant.

High-quality batteries are essential for electric vehicles (EVs), but EV batteries must be sustainable, performant, and reliable. Since cathodes directly influence many aspects of battery performance, developers have focused on producing cathode materials.

Electric vehicle batteries. Image used courtesy of Adobe Stock

LG Chem’s cathode material production facility will specialize in cathodes designed specifically for EVs. The company claims its plant, under construction in Tennessee, will be the largest in North America.

Explaining NCMA Cathodes in EV Batteries

NCMA (nickel cobalt manganese aluminum) cathode materials are among the most popular used in electric vehicles today. As the name suggests, NCMA cathodes comprise nickel, cobalt, manganese, and aluminum, with nickel typically being the dominant component.

The primary function of the cathode in a lithium-ion battery is to facilitate the flow of lithium ions during the discharge cycle, which generates electric current. The specific composition of NCMA cathodes enhances this process and provides several key benefits. First, the high nickel content contributes to a greater energy density, meaning batteries can store more energy for longer periods, extending the range and utility of EVs and electronic devices.

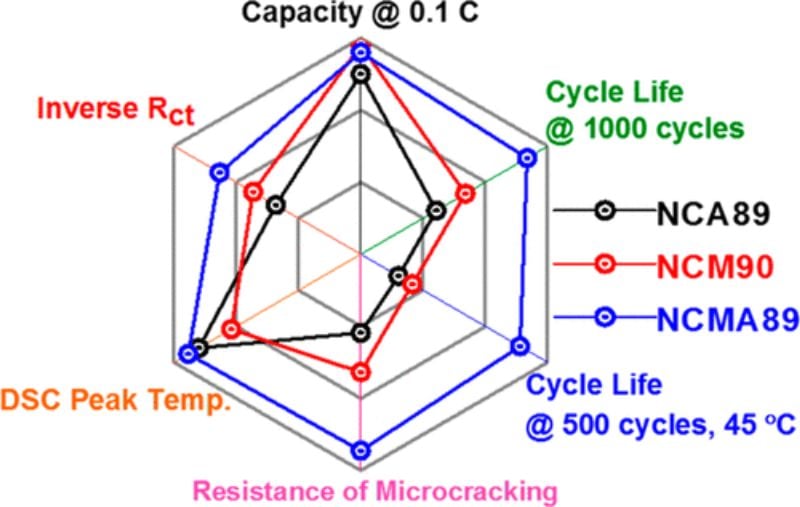

NCMA cathodes can offer better stability and lifetime than NCM cathodes. Image used courtesy of Kim et al.

While high nickel content increases energy density, adding cobalt can improve the battery's life and safety. However, cobalt is expensive and has ethical and environmental sourcing concerns. Since NCMA cathodes incorporate manganese and aluminum, they reduce reliance on cobalt and address these cost and sustainability concerns without significantly compromising the battery's performance. Additionally, including aluminum improves the structural stability of the cathode, enhancing the battery's overall safety and lifespan.

Compared to other cathode materials like LCO (lithium cobalt oxide) or NMC (nickel manganese cobalt), NCMA cathodes offer a superior blend of energy density, safety, longevity, and cost-effectiveness. This unique combination makes NCMA an attractive choice for the next generation of high-performing, long-lasting, and safer lithium-ion batteries, pushing the boundaries of what's possible in electric vehicle technology.

LG Chem’s Cathode Plant

Recently, LG Chem initiated the construction of North America's largest cathode plant in Clarksville, Tennessee.

The $1.6 billion plant specializing in NCMA cathode materials offers a projected annual production capacity of 60,000 tons, enough cathode materials to power approximately 600,000 EVs annually, each boasting over 300 miles of range. Notably, the company aims to operate the plant on 100% renewable energy, aligning with the growing emphasis on sustainability within the industry.

Cathode material from LG Chem. Image used courtesy of LG Chem

The company chose the Tennesse site for its strategic location, enabling efficient customer deliveries and raw material imports. LG Chem plans a $3.2 billion initiative to build cathode plants in Tenessee, stemming from recent contracts with Toyota and GM to supply the companies with cathode materials in North America.

The company expects the cathode plant to commence mass production in 2026 and plans to continuously evolve its product offerings and expand capacity in line with the growing demand for EVs.

Strengthening the North American EV Battery Supply Chain

As the U.S. economy embraces a large influx of electric vehicles, LG Chem’s cathode materials plant is poised to be a strategic asset for the domestic supply chain. By bringing cathode material production to the states, the plant addresses critical gaps in material sourcing, production capacity, and technological advancement, strengthening the country’s position in the global shift towards electric mobility and sustainable energy solutions. As such, it plays a vital role in securing the country's economic and environmental future, making it a key player in the international EV market.