Considerations for Designing a Safe, Reliable Battery Management System

This article describes the most significant risks influencing a battery and what engineers must consider when designing a battery management system.

In designing a reliable battery management system (BMS), engineers must consider the state of the battery, its health, and how it is protected from all possible risks.

Image used courtesy of Adobe Stock

A well-designed BMS should:

- Control the battery’s voltage and current

- Provide thermal management for the battery

- Provide fire protection in case the battery ignites

- Cybersecurity functionality to avoid attacks and data theft

How a BMS Protects the Battery Storage System

A battery energy storage system (BESS) always has a rechargeable battery as the main unit. This complex unit requires a watchful eye and extreme care. This is where the BMS comes in.

A BMS can estimate the battery’s state of charge and health. Due to the estimation of state-of-energy, state-of-power, and balancing cells, a BMS can control the battery’s abilities and its storage system.

The battery’s sensitivity to changes in the working conditions depends on its electrochemistry. Exceeding the operating limits can harm the battery and destroy it. A battery breakdown can be dangerous. For instance, lithium-ion (Li-ion) batteries are flammable, and devices based on these batteries often explode.

A BMS is equipped with various sensors, modules, and fuses and can prevent explosions and other risks. A high-quality BMS has a battery safety system for avoiding ground faults, short circuits, and thermal runaway. This security system allows a BMS to provide data transfer securely and defend a battery storage system from pirated use.

The six key functions of a BMS. Image used courtesy of Integra Sources

With the help of a BMS, you can save the battery, prolonging its life and the life of the BESS. Due to an integrated real-time operating system, a BMS can monitor battery health, predict risks, and prevent them in real-time.

This article focuses on systems using the most widespread product in the battery energy storage world—a lithium-ion battery. It can’t stand too high or too low temperatures, overcharging, and over-discharging. A BMS can serve as a watchful eye for lithium-ion batteries.

Controlling Battery Voltage and Current

There are two main methods for controlling the current and voltage of a battery: protecting a battery from overcurrent and overvoltage in the charging process and saving a battery from Undervoltage in the discharging process.

There are certain limits for charging and discharging recommended for each battery type. In this case, the battery’s voltage fits the state of charge (SOC).

For instance, lithium-ion batteries prefer charging at up to 4.3 V and discharging at not less than 2.3 V. The batteries with Li-ion chemistry can have charge currents ranging from 0.1 C to 1.0 C. As for discharge current, it can be up to 2 C.

Keeping out of these ranges can lead to oxidation, short-cutting, and other improper states. It can negatively influence the battery life period and cause electrical injury, an explosion, and fire.

Sensors can help you control the battery’s voltage and current. Using more sensors leads to high reliability: a BMS can take efficient steps by reading sensor data and analyzing it.

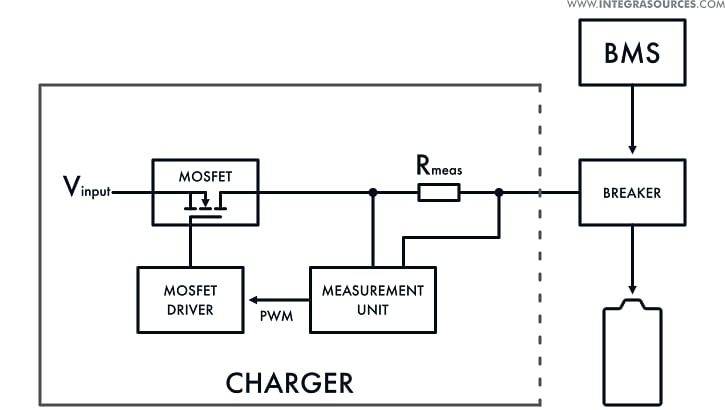

For example, the BMS can stop the charging process by using a breaker to disconnect the circuit when the voltage, SOC, or current exceeds the limit. In the same way, the BMS can stop the discharging process to prevent undervoltage and over-discharging.

The overcurrent and overvoltage/undervoltage protection systems of BMS. Image used courtesy of Integra Sources

It will be efficient to add the functionality of notifying users of the battery’s improper state so a BMS will be able to provide a user with alarm and push notifications and display them on a connected device’s dashboard.

BMS and chargers can use a constant voltage/constant current battery charging method to protect a battery from overcurrent and overvoltage. The point is the following:

A user charges a battery with constant current and carries it off to a determined voltage level. After that, the current goes down, and the battery is charged with constant voltage. The battery is completely charged when the current reaches the lowest possible reading.

A BMS can control voltage and current at both software and hardware levels. To develop an industrial BMS solution, Integra uses basic hardware, including:

- current and voltage transformers

- an amplifier and a buffer with a resistive divider for increasing the magnitude of the output current and voltage

- an ADC for converting the values of the current and voltage to digital signals

- an MCU for reading the signals

Integra’s engineering team wrote the firmware and implemented the following functionality for the MCU, which sends a command to a breaker after comparing measured values with the current and voltage limits.

The process of charging a battery with constant voltage and constant current. Image used courtesy of Integra Sources

How Thermal Management Keeps A Battery Safe

Designing a BMS for lithium-ion batteries requires taking safety precautions. Thermal management plays an essential role in this process. It controls the battery’s temperature, heating, cooling, and air conditioning.

Lithium-ion batteries are highly efficient but can burst because of contact with air and water. Minor changes in temperature or battery condition can lead to short circuits and inflammation. So, thermal management plays a crucial role.

Lithium-ion batteries are recommended to work at the following temperatures:

- 0℃ to 45℃ for charging

- 20℃ to 60℃ for discharging

- 0℃ to 20℃ for storing

Here, thermistors will help an engineer measure the temperature of a battery and its surrounding environment. Thermistors are semiconductor devices whose resistance changes depending on temperature.

It will allow your BMS to compare these temperature values with the recommended limits and take precautions if they are higher or lower. For instance, thermistors or thermal fuses can open the circuit and disable the battery in case of temperatures that are too high.

Present-day BMSes use NTC or thermistors to determine resistance changes accurately and quickly.

The overtemperature protection system of the BMS

In the charging and discharging, a thermal battery management system takes extreme care of lithium batteries. It is necessary to monitor the temperature inside the battery to rescue it from thermal runaway and inflammation. A Li-ion battery must not operate over or under the recommended temperature ranges since it can lead to battery death.

A thermal management system uses a battery fan, cooling and heating system, ventilation, and air conditioning system, so it is an efficient solution for saving a battery from working at out-of-bounds temperature ranges.

A BMS can use a heat dissipation method to eliminate heat dissipation from the battery’s electrochemical reactions. This method includes air and liquid cooling and air and fluid convection. It can be efficient to apply conduction, convection, radiation, and phase changes as well. Adding thermistors and thermostats to your BMS solution will allow you to avoid thermal hazards.

BMS Fire Protection

The system should notify you in case of battery and system failure and inflammation and immediately take steps to stop this process. For that, your BMS should have an efficient fire protection system. However, there are things you cannot always control. For example, manufacturing defects (such as cell packaging and battery plate flaws) can lead to self-ignition.

Examine the battery package, components, and construction. Separators and flame retardants can save a Li-ion battery from thermal runaway and short circuits.

Li-ion battery combustion leads to the spread of smoke, fire, and toxic gases. To avoid this, properly install, maintain, and store the BESS and maintain current, voltage, and temperature limits. In other words, design a solid fire protection system. Smoke detectors can help detect battery combustion, tapping into cell cooling and fire extinguishing systems.

In Integra’s previous projects, our engineers placed a smoke detector in each battery module. It works as follows: The BMS receives a signal from the detector and opens a valve connected to a plumbing system’s pipe. A water leak detector controlled pipeline leakage.

Due to lithium’s reactivity and adverse effects, using water to extinguish Li-ion battery fires can spread toxic gases and cause explosions. It’s better to use foam and dry chemicals. Prepare the system for certification procedures properly and implement reliable fire safety if you plan to bring the system to market.

Integra engineers can deliver bespoke software and hardware BMS solutions that comply with international fire prevention and protection regulations and make your battery storage system reliable and safe.

The fire protection system of a BMS. Image used courtesy of Integra Sources

How to Implement Cybersecurity Features

A BMS can improve your system’s performance and protect it not only on the hardware but also on the software level. You should consider cybersecurity when creating a BESS. A BMS can help you avoid attacks on your system and data theft.

In most cases, modern BESSes are part of the Internet of Things infrastructure. It allows users to access BESSes remotely via Internet connections and control them using mobile apps and portable gadgets. Data transfer is a significant part of this process and requires extreme care since it is an Achilles’ heel for cyberattacks. Unauthorized access and malicious actions can damage BESS components and the battery itself.

The best way to protect your BESS is to implement security features. As a first step, set up authentication procedures to forbid access to the system by unauthorized users.

In one of our BMS projects, we implemented user identification activities such as sending authentication requests. If the authentication is successful, the users get automatically authorized, receive an access rights list, and get checked for their permissions.

For data integrity and security, the communication protocol should have reliable encryption mechanisms that allow a BMS to keep the information confidential at a high level.

Another significant step is component selection. The right choice of chips, modules, and sensors can ensure your system’s immunity to vulnerabilities, cyber-attacks, and security threats.

The Role of a BMS in Battery-Powered Systems

Lithium batteries require careful use due to the peculiarities of their chemistry: They are potentially dangerous and can lead to unpredictable effects harmful to the BESS and its users.

Thus, battery safety is vital to designing a battery management system.

If designed right, a BMS can protect the battery from under- and overvoltage, overcurrent, under- and overtemperature, and spontaneous ignition. Moreover, a BMS can provide cybersecurity to protect the system and its users from malicious activities.