High-Frequency Power Transfer Paves the Way for Wireless EV Charging

The main difference between wireless charging of a mobile phone and an electric vehicle is the power levels used. What challenges do high-power EV wireless charging face?

This article is published by EEPower as part of an exclusive digital content partnership with Bodo’s Power Systems.

Many plug-in electric vehicle owners rely on a heavy and expensive cable to connect the vehicle to the charger. The cable is costly because it must be thick enough to carry the required peak charging current (typically from 11 kW up to 100 kW or more), tough enough to withstand being carelessly thrown in the back of the car or used in inclement weather and be robust enough to withstand repeated plugging and unplugging operations. Even so, cables and connectors have a limited lifetime and will eventually become unsafe, worn, or damaged by daily use. Would a better solution be to dispense with them altogether?

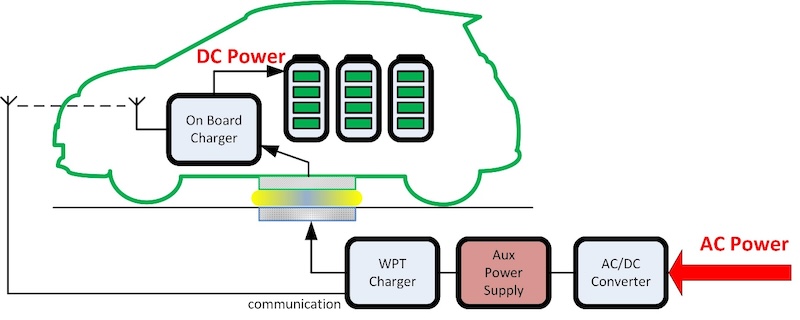

Figure 1 shows a concept for a wireless electric car charger. The vehicle is parked over a charging coil, and power is transferred by inductive wireless power transfer to recharge its batteries. Wireless communication ensures power is transferred when safe, much like a modern mobile phone communicates with a Qi-enabled charger pad to ensure no foreign objects are present in the charging field before power is applied.

Figure 1. EV wireless charging concept. Image used courtesy of Bodo’s Power Systems [PDF]

The main difference between charging a cell phone vs. an electric vehicle is the power level used. Efficiency must be maximized for a high-power EV wireless charger, whereas phone chargers are typically only 70% efficient, according to the Wireless Power Consortium. This is acceptable for a low-cost commodity product but is wasteful for an EV wireless charger, where a system efficiency closer to 85% is required (AC to DC power).

Power transfer efficiency can be improved in three ways: more tightly coupled magnetic circuits, higher frequency operation, and better matching. But first, let's look at the basics of wireless power transfer technology.

Wireless Power Transfer Basics

Wireless power transfer (WPT) technology dates back to the late 1800s when Heinrich Hertz demonstrated high-frequency spark gap wireless power transfer using two parabolic reflectors to focus RF radiation. Nikola Tesla also experimented with coupled electromagnetic resonance circuits just before the turn of the century, but there is no evidence that he succeeded in transferring meaningful amounts of electrical power. The earliest successful demonstration of Inductive power transfer was in 1910 to illuminate a light bulb held over an open transformer, but again, this was not turned into a practical wireless electricity product. Despite the lack of commercial success, these early pioneers laid the groundwork for some of the main wireless power transmission technologies used today:

| WPT Method | Range | Frequency | Uses |

| Inductive | short | kHz-MHz | Electric toothbrushes |

| Magnetic Resonant Coupling | mid | kHz-MHz | Phone Chargers, EV chargers |

| Capacitive Coupling | short | kHz-MHz | Biomedical implants |

| Microwave | long | GHz | Satellites |

| Laser | long | THz | Drones |

For capacitive and magnetic WPT systems, the energy stored in a unit volume of air between the transmitter and receiver is given respectively by:

\[W_{e}(electric\,field)=\frac{1}{2} \varepsilon_{0}E^{2}\]

\[W_{m}(magentic\,field)=\frac{1}{2} \mu_{0}H^{2}\]

Where E and H are the intensity of the electric and magnetic fields, respectively, and are the permittivity and permeability values for free space. As it is higher, about a thousand times more energy can be transferred in a coupled magnetic field than in a capacitively coupled field when practical voltage and current limitations are considered. Therefore, inductive and magnetic resonance coupling lend themselves to the highest power transfer.

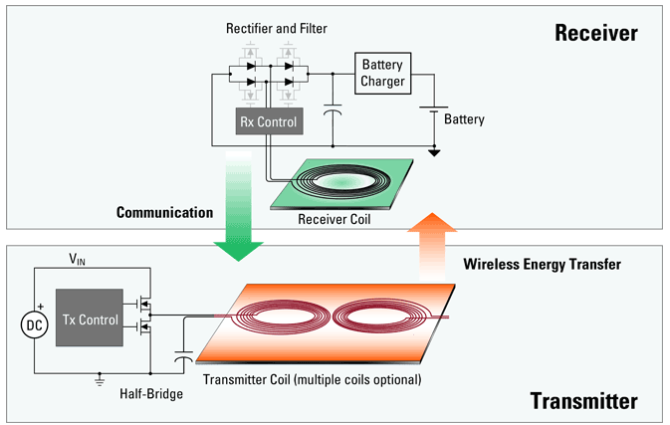

Essentially, inductive charging systems use a transmitter coil to generate a localized magnetic field, which is coupled into a receiving coil via mutual inductance (Figure 2):

Figure 2. Inductive wireless power transfer schematic (Figures 2, 3, and 4 are from the RECOM AC/DC Book of Knowledge, Chapter 10.) Image used courtesy of Bodo’s Power Systems [PDF]

The mutual inductance, M, between the transmitter and receiver coils is given by the deceptively simple equation:

\[Mutual\,Inductance,M=k\sqrt{L_{t}L_{r}}\]

Where Lt and Lr are the winding inductances of the transmitting coil and receiving coil, respectively, and k is a coupling coefficient, which is dependent on the dimensions, number of turns, and alignment (orientation and separation) of the coils (Figure 3):

Figure 3. Effect of various flat coil misalignments on inductive power transfer efficiency. Image used courtesy of Bodo’s Power Systems [PDF]

The coupling coefficient can be enhanced by inserting intermediary coils, which act as ’magnetic lenses‘ to focus the magnetic flux (Figure 4). Higher power resonant inductive coupling systems may use three or more coils. These intermediary coils are resonant tank circuits with a capacitor in parallel with the winding which resonates at the frequency of the alternating magnetic field (Figure 5). The resonators boost the effective magnetic field strength from the transmitting coil and concentrate the effective received field into the receiving coil, increasing the coupling efficiency significantly. Additionally, even if only part of the projected magnetic flux is intercepted by the intermediary circuits, they will still resonate, so separation distance and alignment are not so critical as with two simple flat coils.

Figure 4. Resonant inductive coupling using intermediary resonators. Image used courtesy of Bodo’s Power Systems [PDF]

Figure 5. Equivalent circuit model of a WPT with intermediary resonators. Image used courtesy of Bodo’s Power Systems [PDF]

The intermediary resonators do not have to be placed symmetrically as shown in Figure 4 – if the limiting factor for power transfer is sufficient magnetic flux, then paired resonators placed close to the transmitter coil will magnify the local magnetic field through the coupling factors k12 and k23 for a stronger coupling factor k34 to the more distant receiver coil.

Such intermediary coils are essential for WPT applications where the distance and alignment between the transmitting and receiving coils are not fixed, for example, on an electric road that recharges a moving vehicle driving over it. Tesla, amongst other companies, has built prototype in-road charging systems where the vehicle has underbody spring-loaded metal power connectors to recharge while on the go, but Detroit is the first city in the US that has implemented a contactless in-road charging system based on wireless power transfer. The system successfully demonstrated a charging rate of up to 19 kW.

High-Frequency Wireless Power Transfer

It would be possible to carry out charging by induction using the low-frequency 50/60 Hz alternating current available from the mains supply, but this would be inefficient for higher powers.

The higher the transmission frequency, the more power can be transferred according to:

\[P_{out}=\omega_{0}MI_{t}I_{t}\]

Where the output power, Pout, is equal to the angular frequency at resonance, ωo, multiplied by the mutual inductance, M, the current in the transmitting coil and the resulting induced current in the receiving coil, Ir. Thus, the transmitted power is directly proportional to the frequency of the alternating magnetic field. However, core eddy current and switching losses increase with higher frequency, so an optimum WPT operating frequency is dependent on other system parameters for peak inductive power transfer efficiency.

With existing high-power switching technology, a resonant frequency of between 20 kHz and 150 kHz achieves the best results.

The final significant factor affecting the system efficiency is matching the supply, coil, and load resistances. The maximum power transfer efficiency (PTEmax) can be derived from the following relationship (at resonance):

\[PTE_{max}=\frac{\omega_{0}^{\,\,\,2}M^{1}R_{L}}{R_{t}(R_{r}+R_{L})^{2}+\omega_{0}^{\,\,\,2}M^{2}(R_{r}+R_{L})}\]

Where RL, Rt, and Rr are the load, transmitter, and receiver ohmic resistances, respectively.

The load, receiving, and transmitting coil resistance should all be the same for best performance.

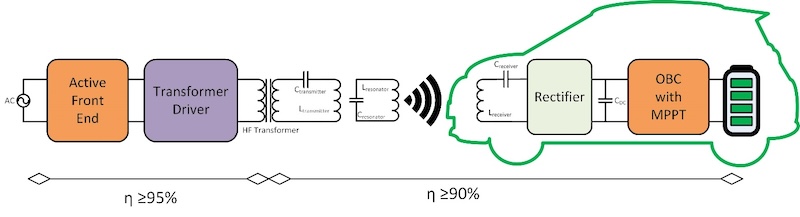

This creates some practical problems in the design of the WPT system. The high current power supply front end and inverter for the transmitter have a very low internal impedance, so a high-frequency impedance matching transformer may be needed to get the highest coupled transmission power to the coil. Similarly, the load is a battery pack with a non-linear internal resistance characteristic, which is dependent on its state of charge, so a DC/DC onboard charging (OBC) unit will be required, which can be impedance-tuned for optimum power reception, much like the maximum power point tracking (MPPT) circuits used in photovoltaic DC/DC converters (Figure 6).

Figure 6. WPT power stages with anticipated conversion efficiencies. Image used courtesy of Bodo’s Power Systems [PDF]

To meet the efficiency targets, the active front end (AC to DC conversion and power factor correction) will need to use a bridgeless totem pole configuration or similar (Figure 7), and the inverter will need to use a full bridge or variant of an LLC topology. Both designs will need to use several isolated transistor gate drivers.

Figure 7. GaN Totem pole bridgeless rectifier example circuit. Image used courtesy of Bodo’s Power Systems [PDF]

With high power switching designs, it is often difficult to balance out the power ground stray inductances in each leg, leading to asymmetric performance and switching instability. Isolating the high-side and low-side gate drivers eliminates this problem (Figure 8).

Figure 8. Full bridge gate driver example circuit. Image used courtesy of Bodo’s Power Systems [PDF]

RECOM offers a range of compact gate driver power supply modules with high isolation, asymmetric output voltages for optimal power transistor switching, and a wide operating temperature range, making them ideal for such high-power designs, including bidirectional circuits.

In the electric vehicle, another active rectifier circuit will convert the AC from the receiving coil to charge an intermediary bus capacitor, CDC. This unregulated DC bus voltage can supply a high-power digital DC/DC converter unit such as RECOM’s 15 kW OBC design (Figure 9).

Figure 9. RECOM’s 15 kW (parallelable up to 75 kW) high voltage onboard charger. Image used courtesy of Bodo’s Power Systems [PDF]

This 15 kW converter design will accept a wide DC input voltage range of 25 VDC up to 280 VDC and boost the output voltage to a programmable 200 V-800 VDC to charge a high-voltage EV battery stack, with an efficiency exceeding 97%. The built-in MPPT circuit optimizes the power transfer efficiency during the entire charging cycle. The CAN-bus interface allows communication with standard battery management system controllers and permits active load sharing between paralleled units.

An Alternative to Wired EV Charging

Wireless power transfer is a viable alternative to wired electric vehicle charging systems in terms of technology, even if it is not mainstream due to the higher cost. As EVs become the norm rather than the exception, the ease of use and convenience of simply driving up to a parking slot and charging the battery wirelessly will make WPT more attractive, especially as the technology already exists for the vehicle to move and park itself. Ultimately, on-the-go WPT charging using electric roads will eliminate the “range anxiety” of usi“g EVs, enabli”g the battery to be fully charged at the end of the journey, not just at the start.

This article originally appeared in Bodo’s Power Systems [Bodo’sagazine.