ROHM, Vishay, SemiQ Release Power Semiconductors

ROHM’s 100 V Schottky Barrier Diode uses a trench MOS structure to lower reverse recovery times, while Vishay and SemiQ release IGBT and silicon carbide (SiC) power modules for industrial and solar inverter applications.

As electric vehicles, renewable energy, and industrial applications demand more power, efficiency, and longevity, power semiconductor technology must continuously improve. ROHM Semiconductor, Vishay, and SemiQ recently released power semiconductors with upgraded features and durability. Here are the product details.

Vishay’s half-bridge IGBT. Image used courtesy of Vishay

ROHM’s Schottky Barrier Diodes

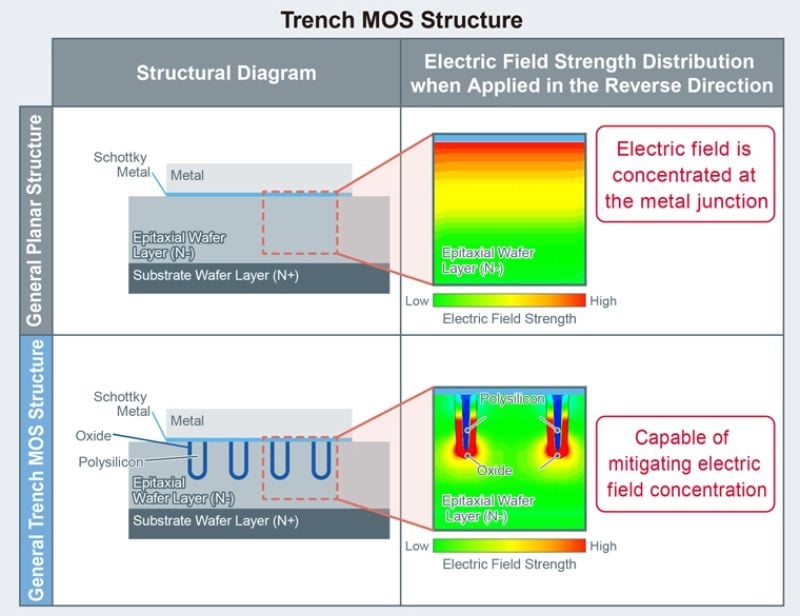

ROHM Semiconductor has released its YQ series Schottky barrier diode (SBD) rated to 100 V and available in various surface-mount package options. The SBD uses a trench MOS structure and proprietary design to significantly improve reverse recovery time in power supply and protection circuits for automotive, industrial, and consumer applications.

SBDs are vital components in rectification and protection circuits for power supplies and similar circuits. They offer low forward voltage drops and fast switching capabilities to minimize power losses.

SBD structure comparison. Image used courtesy of ROHM

For SBDs, a trench MOS structure provides a lower forward voltage drop (VF), but the tradeoff is typically a longer reverse recovery time compared to planar topologies. This results in increased power losses during the switching transition between the diodes' forward and reverse-biased states.

ROHM’s YQ series is the first of its SBD products to use a trench MOS structure. According to ROHM, the proprietary design allows the YQ series to deliver a best-in-class reverse recovery time (tRR) of only 15 ns, lowering recovery losses by more than 30% and total switching losses by roughly 25%.

Also, with the trench MOS structure, the lower resistance of the epitaxial layer results in a 7% lower VF, while a weaker electric field concentration reduces reverse current (IR) power losses by more than 80%.

Half-Bridge IGBT Power Modules from Vishay

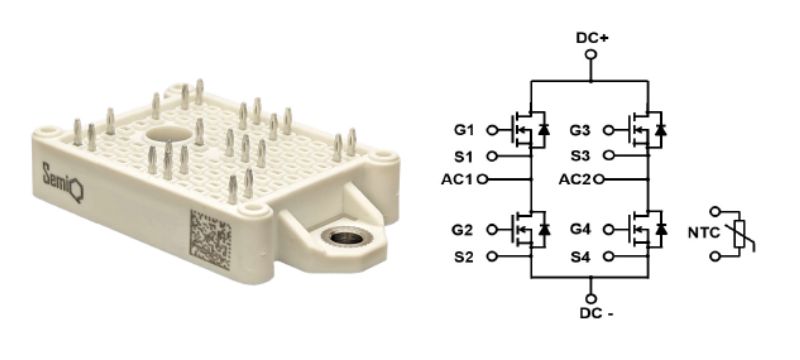

Vishay Intertechnology has released five half-bridge IGBT (insulated-gate bipolar transistor) power modules based on their trench IGBT technology and packaged in a revamped INT-A-PAK (IAP) package. Along with IGBTs, the modules also incorporate Gen IV FRED Pt anti-parallel diodes to help with reverse recovery performance. Each module handles withstand voltages up to 650 V and peak currents ranging from 100 to 200 A.

According to Vishay, best-in-class collector-to-emitter voltage (VCE(on)) and turn-on switching loss (Eoff) specifications contribute to reduced conduction and switching losses. For an IGBT, channel conduction losses are generally defined by the on-state voltage drop and current levels.

IAP half-bridge IGBT power module. Image used courtesy of Vishay

Vishay’s IAP modules are designed for reliability, with a single housing to accommodate multiple high-power components for more power density. The package is fully isolated from the metal base to support a common heat sink configuration across multiple modules, while a low junction-to-case thermal resistance further facilitates heat dissipation.

In contrast to more exotic silicon carbide (SiC) and gallium nitride (GaN) solutions, the new industrial-grade power modules, built on more mature IGBT technologies, are targeted for lower-frequency inverter applications (up to 30 kHz) in railway, energy distribution, and storage systems. These applications can typically accommodate larger form factors but still demand high voltage capabilities and power conversion efficiency.

1,200 V SiC Power Modules from SemiQ

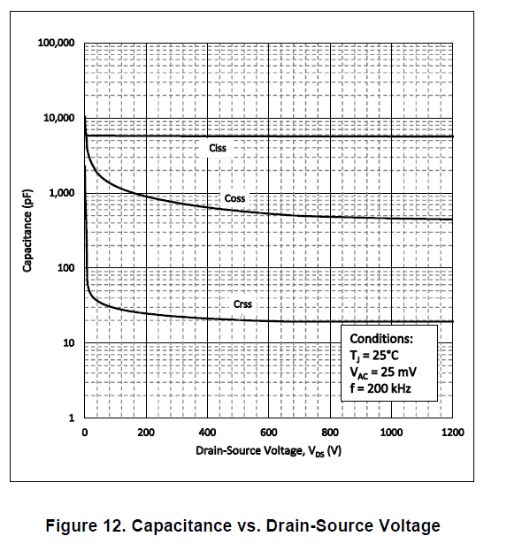

New full-bridge power modules from SemiQ use the latest silicon carbide technologies to offer a solution that can accommodate voltages up to 1,200 V and deliver conversion efficiencies as high as 98% in solar inverter, EV charging, and drivetrain applications.

QSiC full-bridge, 1200 V SiC power module. Image used courtesy of SemiQ

The five modules, each constructed with four SiC MOSFETs, are an extension to SemiQ’s QSiC family of modules and can accommodate currents of more than 100A. On resistances as low as 20 mΩ minimize conduction losses, reducing heat dissipation and allowing for smaller heat sinks. Combined with high-frequency switching capabilities (up to 200 kHz) and using performance ceramics, the modules support high-power density designs.

QSiC module performance characterization to 200 kHz. Image used courtesy of SemiQ

To ensure a predictable and steady gate threshold, SemiQ performs gate burn-in testing at the wafer level to weed out lower-performing devices. Each part also undergoes extensive temperature, gate, drain, and other stress testing, including operational testing above 1,400 V.