Understanding Cell and Battery Construction

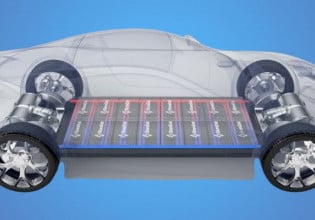

In this article, learn the aspects of cell and battery construction, including electrodes, separators, electrolytes, and the difference between stacked plates and cylindrical construction, as well as how cells can be connected in series to form strings or parallel to create battery banks.

The construction of cells and batteries is a fundamental pillar in energy storage.

This article delves into the components constituting these units, encompassing electrodes, separators, and electrolytes. A comparative analysis between stacked plate and cylindrical constructions is presented, as well as the significance of cell boxes and the distinction between primary and secondary chemistry. The discussion extends to the configuration of cells in series, forming strings, and in parallel, creating battery banks.

One source of confusion is the difference in meaning between a cell and a battery. The term 'battery' generally means 'a row of…' as in a battery of guns or battery hens. A battery is a row of cells. The typical automotive battery of 12 volts is made from six cells of nominally 2 volts each.

Electrodes

Electrodes, also known as 'plates', are the current collectors of the battery. The negative plate collects the electrons from the electrolyte, becoming negatively charged in the process.

The positive plate, on the other hand, collects the positively charged ions from the electrolyte, giving up an electron to each ion and therefore becoming positively charged in the process.

Electrodes are metallic or made up of metallic pastes that are chemically charged when in the company of an electrolyte. They may be round but are generally flat or made of flat sheets rolled or folded into a coil or bundle that keeps the positive and negative plates close together.

Although a lead–acid battery could be thought of as having pure lead plates, the lead metal actually contains about 10% antimony to increase the strength of the lead plate.

Separator

Electrodes that are kept close together will occasionally touch, causing short circuits and resulting in high fault currents. To stop these short circuits, a separator is usually placed between opposing plates, as shown in Figure 1. Separators in the lead–acid batteries were once simply dried-out wood, but as technology produced better materials, the separator became a porous sheet of thin plastic, allowing the plates to be much closer together.

Figure 1. Typical wet-cell construction. Image used courtesy of ResearchGate

As the search for lighter and smaller batteries continues, new technologies using a separator material with a metallic electrode screen printed onto it is not only possible but probably already in use.

Electrolyte

Together with the electrodes or plates, the electrolyte forms the trio that makes the chemical reaction. Remember that there are generally two (or more) chemical reactions simultaneously: one at the positive plate and one at the negative plate.

The electrolyte conveys the ions from one plate to the other. Therefore, the thicker the electrolyte, the greater the distance that the ions travel. A more fluid electrolyte would allow the ions to travel more freely but is more likely to spill or overflow. Therefore gel- or paste-type electrolytes have become common, but the batteries must be made to dissipate heat so the pastes and gels do not boil or dry out. Gassing can also result in permanent damage to batteries.

Stacked Plate vs. Cylindrical Construction

Older lead-acid batteries were made from cast lead plates onto which a paste was loaded. These plates and separators were then stacked, generally with negative plates on both sides, so there was always one more negative plate than the positive plate. Batteries were often called 7-plate, 9-plate, or as many as 17-plate batteries.

Another form of construction suited for thinner plates forms the plates into rolls that fit into a cylinder, which becomes the cell. The overall design aim is to increase the area of the plates, reducing internal resistance.

Cell Box

The cell pack or pack of plates and separators is put into a cell box or cylinder as mentioned above, which provides a secure home for the pack, protecting it from mechanical damage and holding the pack in a position where the positive and negative connections can be attached to it.

The bottom of the cell box has a space for any foreign particles to collect so they do not short out the bottom of the plates. This space varies with the design of the battery but can become full, resulting in a shorted cell, which can result in a very hot battery.

Otherwise, the box is a snug fit for the plates to prevent them from moving about, especially in mobile applications such as road use. The top of the cell box allows some space above the acid so it does not spill or splash out. This also allows some bubbling without acid being vented to the outside world.

The top of the cell box is usually enclosed by a glued or welded top cover with a vent cap that allows the cell to breathe, venting off any gas or vapor while keeping dust and dirt out.

The other openings in the top cover are for the terminals, which in most cells simply join with the next cell.

Primary vs. Secondary Chemistry

Batteries and cell technologies are divided into primary and secondary cells. Secondary cells can easily, or at least economically, be recharged once flat (exhausted of energy).

Primary cells, therefore, are often considered non-rechargeable, which is not quite true. Many primary cells can be recharged, but the process is inefficient and may produce toxicity or pollution.

Alkaline cells were not considered rechargeable until a few years ago when a suitable charger was designed and built. Then some battery manufacturers began making cells considered rechargeable by design.

Cells in Series – Strings

When cells only produce a small terminal voltage, they are connected in series to produce a higher total voltage, the battery terminal voltage. Remember that a 'battery' is generally considered a number of items in a row. When separate cells are connected in series, they are often called a 'string' of cells, a terminology that has become more common in solar cell systems. A string of cells, in other words, is a battery of cells.

Example 1: A 12 V high-power torch uses 'D' cells with a terminal voltage of 1.5 volts. How many cells are required?

\[Cells=\frac{V_{Battery}}{V_{Cell}}=\frac{12}{1.5}=8\,cells\]

Cells in Parallel – Banks

When multiple strings of cells, or batteries of cells, are connected in parallel to increase the total current capacity, it is referred to as a battery bank.

Example 2: If 36 lead–acid cells are connected in banks of batteries to produce 12 V, how many banks of batteries are there?

\[Cells=\frac{V_{Battery}}{V_{Cell}}=\frac{12}{2}=6\,cells\,per\,battery\]

\[Banks=\frac{36}{6}=6\,banks\,of\,6\,cells\]

Takeaways of Cell and Battery Construction

A deep understanding of cell and battery construction is essential for comprehending their functionality and optimizing performance. The electrodes, separator, electrolyte, and cell box are crucial components that contribute to the overall operation of cells and batteries. The choice between stacked plates and cylindrical construction, as well as primary and secondary chemistry, determines the suitability of cells for specific applications. Additionally, connecting cells in series or parallel enables the manipulation of voltage and current outputs.