The Role of GaAs Diodes in High Performance Power Conversion

This article highlights 3-5 Power Electronics Silicon feature dynamic switching characteristics similar to Silicon Carbide (SiC) to give excellent performance at lower cost.

GaAs diodes are a new breed of wide bandgap power semiconductors which offer designers a way to trade-off efficiency and cost in high performance power conversion. Pioneered by 3-5PE Semiconductor (3-5pe.com), GaAs technology provides the low conduction loss capability

Introduction

High voltage Silicon diodes have low forward conduction drop but impose significant dynamic losses in the power converter due to their reverse recovery behaviour. SiC diodes show negligible reverse recovery behaviour but do exhibit higher body capacitance and greater forward conduction drop than Silicon. With GaAs technology able to offer useful features of both Silicon and SiC, this article explores an exercise undertaken to compare performance in a 10kW, 100kHz phase shifted full bridge (PSFB). The results from benchmarking GaAs, SiC and Hyperfast Silicon diodes in this application show that GaAs diodes enabled overall efficiency equal to SiC at a significantly lower cost point.

Why GaAs?

Cost - The raw material cost in the wafers used for GaAs diodes and their inherently lower manufacturing process cost represent a significant opportunity to achieve the performance of SiC at a significantly lower price point. The typical cost of packaged GaAs diodes is around 50% to 70% of that of comparable SiC parts.

Availability – GaAs as a material is already used widely in RF applications and is the second most used semiconductor material in the world. Due to its widespread use, it is available from multiple sources with manufacturing processes similar to Silicon. These factors all support a low cost base for the technology.

Soft or Hard Switching?

Whist the performance of SiC offers a significant improvement in diode and transistor switching characteristics compared to mainstream Silicon, the trend in recent years is to use soft-switching topologies to extract the very highest levels of performance across the entire converter. These soft switching topologies are a perfect fit for GaAs diodes to allow the designer to benefit from lower conduction loss than SiC without suffering the additional dynamic losses which normal Silicon would incur.

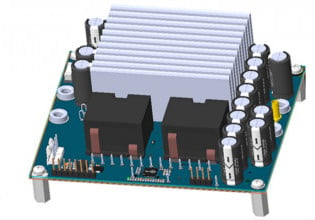

Figure 1: Benchmarking Diode Comparisons

Soft switching topologies often run higher RMS currents in the power semiconductors for a given power output due to the circulating resonant energy required to force the zero voltage transitions. A technology such as GaAs with lower forward voltage drop can reduce the losses causes by this circulating energy and fully exploit the advantages of zero voltage operation of the switches.

Power Loss Due to Diodes

The ‘ideal’ diode would perform its function without incurring any loss but any real diode, including wide bandgap devices, deviate from this ideal with different aspects of their real world behaviour leading to power loss. In most converters, the contribution of the loss due to the secondary side diodes can be grouped into one of three main areas:

- Non-zero forward voltage drop which leads to conduction loss when the diode conducts current. This loss mechanism is topology dependent but generally not a function of frequency.

- Loss due to the body capacitance of the diode with higher capacitance leading to higher losses. This is topology/frequency dependent and resulting loss is imposed on other components in the converter.

- Loss due to reverse recovery effects which are topology/frequency dependent. These losses are realised in the diode and other components in the converter.

The relative level of the loss types described above depends on the individual diode characteristics, topology choice and operating frequency. Forward conduction losses are relatively easy to calculate whereas losses due to diode capacitance and Trr are more complex.

Comparison of Diode Behaviour

Three diodes were compared during the benchmarking tests, with headline comparison as shown in Figure 1.

Comparison of the data shows that, from a forward conduction performance perspective, both Silicon and GaAs perform better, especially at high junction temperatures. From a switching perspective, SiC has significantly higher capacitance but essentially zero reverse recovery time. The question is, for our 10kW PSFB application, how will these diode characteristics impact overall efficiency?

PSFB losses Due to the Diodes

Figure 2 shows a typical PSFB topology with the diodes being benchmarked in positions D1 to D4.

The PSFB operates by running the Q1/Q3 and Q2/Q4 transistor pairs at 50% duty each with control of power flow managed by controlling their relative phase. This operation allows for the primary side devices Q1-Q4 to operate with zero voltage switching over a wide range of load conditions.

The combined capacitance of D1-D4 added to the distributed capacitance of the power transformer and PCB results in a resonant voltage across D1-D4 during switching transitions.

Figure 2: PSFB Topology

To prevent damage to D1-D4, a snubber is used to clamp the resonant voltage to acceptable levels. In the PSFB, quantification of the energy absorbed by the active snubber is a direct way to benchmark the impact of the dynamic characteristics (Capacitance and Trr). The combined knowledge of the overall converter efficiency with snubber dissipation allows the diode behaviour to be accurately benchmarked in this application.

Benchmarking Results

A prototype converter was designed for an output profile of 500V/30A/10kW max and Figure 3 shows an example plot from the converter running at 330V/20A output from 600V input. The blue trace (C3) in the scope plot shows the voltage measured across the active snubber, and since the clamp power is a direct function of the clamp voltage, the active snubber was designed to operate with its own control loop to allow the user to set the clamp voltage at a fixed level. In the example plot of Figure 3, this is 800V.

With the design parameters as detailed in Figure 2, an output profile as shown in Figure 4 is possible with colored areas showing the region where ZVS of the primary MOSFET’s occurs and contours showing the required phase shift. Benchmarking tests were performed with a fixed 600Vdc input and a constant current load used on the output with phase shift then changed set the output voltage. The efficiency and snubber power dissipation were measured as a function of output voltage for output current of 10A, 15A and 20A.

Several conclusions can be drawn from the results in Figure 5:

- Overall converter efficiency of the GaAs and SiC based solutions is almost identical, especially at higher load currents. At higher output currents, the slightly higher snubber losses due to the GaAs finite Trr are offset by the lower conduction losses to give the same overall efficiency.

- Hyperfast silicon efficiency is very poor in this application due to high levels of snubber dissipation (i.e. significant losses related to the Trr). Testing with Hyperfast Silicon was restricted to low powers due to the high snubber power levels measured.

- GaAs and SiC snubber power show a similar behaviour indicating the additional losses due to the GaAs finite Trr is largely offset by the higher native capacitance of the SiC device.

Figure 3: PSFB Converter Operating Waveforms (C1/C2 are the voltages developed by the Q1/Q3 and Q2/Q4 pairs, C4 is the voltage across output rectifiers D1-D4 and C3 is the current in L2)

Figure 4: PSFB Output VI Map with ZVS Region and Contours of Constant Phase Shift

Following this empirical work, an analytical model has been developed to model the snubber losses as a function of diode capacitance and Trr. The analysis shows that during the Trr period, extra energy is loaded into the resonant circuit which then leads to extra clamp dissipation. For a given operating point, the snubber power is therefore a function of both diode capacitance and Trr. In the case of the PSFB detailed in this article, for the operating point of 500V/20A output, the analytical model can be used to predict snubber loss as a function of diode capacitance and Trr. This then allows the behaviour of the three diode types to be compared as shown in Figure 6.

Figure 6 shows that for GaAs and SiC, the snubber power is approximately the same with the benefit of the zero Trr in SiC being offset by its higher native capacitance. In the case of Hyperfast Silicon, the benefit of low diode capacitance is swamped by the much higher power levels due to long reverse recovery. The low native capacitance and Trr of GaAs gives dynamic performance like SiC with the added benefit of reduced forward conduction losses.

Figure 5: Benchmarking PSFB Efficiency (left) and Snubber Dissipation (right) for GaAs, SiC and Hyperfast Silicon

Figure 6: Snubber Power as a Function of Diode Trr and Capacitance for PSFB Running at 500V/20A Output

In the prototype PSFB, the transformer, output inductor and PCB layout gives a total loading capacitance of 300pF. The data presented in Figure 6 includes this baseline capacitance in all cases and the total diode capacitance is based on the contribution of four diodes.

Conclusions

When looking at overall converter efficiency, it is important to understand all dominant loss mechanisms including those due to diode dynamic characteristics. It has been shown that combination of low forward voltage drop, low capacitance and low/stable Trr in GaAs diodes provides an excellent combination of characteristics for use in soft switching applications such as the phase shifted full bridge. High performance power electronics in high growth applications, such as EV charging, can benefit significantly from the system level cost down opportunities which GaAs diodes offer. Detailed knowledge of the behaviour of the forward conduction and dynamic losses caused by diodes in real applications equips the designer with the tools to optimize performance and cost.

This article originally appeared in Bodo’s Power Systems magazine.

About the Author

Dr. Iain Mosely works as the Technical Director of Converter Technology. He is responsible for ensuring that Converter Technology is always positioned to provide the highest quality custom power solutions to their growing global customer base. He is highly skilled in the field of power electronics, power supplies and electronics. He earned his PhD in Power Electronics at the University of Sheffield located in England.