1200V Hyperfast Diodes and Their Applications

This article introduces the applications of 1200V Hyperfast diodes and discusses hard switching, soft switching and power losses in diode behavior.

In our modern society, electricity is becoming an ever more important resource of energy. Common examples of energy users and producers are computing equipment (desktop computer, tablets, but also server farms including uninterruptible power supplies), communication equipment (mobile phones, base stations), electric vehicles (traction and battery charging), PV energy harvesting equipment (solar energy farms) and wind turbines (wind farms). Handling the electric energy efficiently has become essential; 1200V diodes can help.

High voltage

It is a well-known fact in electric energy transfer that Ohmic losses in low voltage systems have a larger impact on efficiency than in high voltage systems. It is for that reason that new standards for mobile phone and tablet charging have been developed (USB-PD) that allow these devices to be charged from 9V, 12V or even 20V sources, where in the early days 5V was the standard.

Of course, mobile phones and tablets are more or less low power systems (in the order of 1 to 10 Watts), but a similar tendency can be observed in higher power systems (1 kW and above).

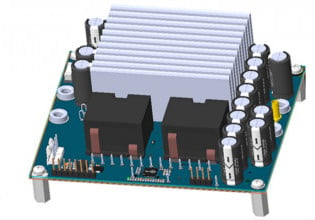

High power electric power conversion systems like UPS, PV inverters and EV chargers are commonly built using DC/DC converter building blocks like Boost/Flyback Converters, Buck/Forward Converters and Resonant Converters. Flyback and Forward Converters are basically the isolated counterparts of the Boost and the Buck Converter respectively.

Traditionally the highest DC voltage levels in this kind of systems used to be around 400V. In many new high power systems, an internal DC voltage of 700V or above is used in order to benefit from efficiency advantages that can more easily be realized by using higher voltage. Basically for the same reason why many modern mobile phones use USB-PD voltage levels of in the order of 12V and not the traditional 5V USB level.

![]()

Fig. 1 Block diagram of a UPS system with various DC/DC building blocks

Hard switching, soft switching and power loss resulting from diode behavior

When it comes to the switching behavior of DC/DC converters, there’s essentially just hard switching and soft switching. Bipolar pn-junction diodes behave differently under hard switching and soft switching circumstances. This can be illustrated by examining the operation of a boost converter in continuous conduction mode (CCM) and of an LLC resonant converter. The CCM boost converter is essentially hard switching, the LLC resonant converter is essentially soft switching.

![]()

Fig. 2 Principle diagram of a boost converter

Hard switching

A CCM boost converter is often used as the power factor correction (PFC) circuit in a power converter system. When, at time t1, switch Q1 is closed the current in inductor L1 (IL1) builds up while the current in diode D1 (ID1) stops to flow. When Q1 is opened at time t2, the current starts to flow through the diode. At the moment that D1 must start to conduct the current (at time t2) only a low concentration of charge carriers (electrons and holes) is present in the drift region of the diode. That makes the initial impedance of the diode relatively high, which results in a high voltage drop (Vfr) across the diode. After a certain time (tfr – mostly in the order of 10 to 100 ns) sufficient charge carriers have been injected into the drift region, the impedance of the diode drops dramatically and the voltage drop across the diode is reduced to the static VF level for the specific forward current. The energy loss due to diode switch-on (switch-on loss) can be approximated by:

The energy Esw-on is completely dissipated in the diode itself.

After switching on, the current through the diode continues to flow and ramps down. Ramp down continues until switch Q1 is closed again. The energy dissipation during the diode conduction period is:

Which can be estimated to be approximately equal to:

Where VF' and IF' are the average VF and IF levels respectively. All conduction loss is dissipated in the diode.

At the moment Q1 is closed the sequence repeats.

The current that flows in diode D1 at the moment it’s being switched off (t1) significantly deviates from zero. Under that circumstance, a bipolar diode cannot block the current instantaneously. In a bipolar diode, the stored charge in the drift region must be removed before the diode can block the current flow. The reverse current associated with the extraction of the stored charge can clearly be recognized in Figure 3.

![]()

Fig. 3 Current waveform in the diode of a CCM boost converter (simulated); black = IL1, red = ID1

Removal of the stored charge (Qs) leads to power loss: switch-off loss (Esw-off). The power loss associated with switching off is proportional to the voltage trajectory that the stored charge need to travel; in a normal boost converter that voltage trajectory is equal to the output voltage of the boost converter (Vout); namely the stored charge was initially at Vout level and is ‘transported’ to ground potential (0 V) because Q1 is closed.

The stored charge Qs is the product of the current flowing in the diode (IF) and the (ambipolar) charge carrier lifetime τa.

Combining the above two equations, and knowing that switch-off occurs at t1, the expression for the switch-off loss is:

The energy Esw-off is normally only partially dissipated in the diode itself; generally, a lot of the energy will be dissipated in switch Q1.

![]()

Fig. 4 Principle diagram of an LLC resonant converter

The ambipolar charge carrier lifetime τa is not a constant; lifetime decreases with current density in the silicon device. That makes it interesting to consider to use a smaller diode in order to reduce power loss in the system as a whole, especially when switching loss happens to be already dominant over conduction loss. Although the conduction loss will increase when a smaller diode is applied in an application, that loss may be more than compensated by the reduction of switching loss. See also the text box “Conduction loss versus switching loss”.

Charge carrier lifetime increases with temperature. Therefore it makes sense to try to keep the operating temperature of a bipolar diode low in order to keep switching loss low.

![]()

Fig. 5 Current waveforms in the diodes of an LLC resonant converter (simulated); blue = ID1 and ID4, red = ID2 and ID3

Soft switching

An LLC resonant converter can often be found as a building block in a UPS or PV inverter. The switches Q1 and Q2, together with L1 (the magnetization inductance of the transformer), L2 (the leakage inductance of the transformer) and C1 (the series capacitance of resonating circuit) create a sinusoidal (or piecewise sinusoidal) current flowing out of the secondary side of the transformer. That sinusoidal current is rectified by the diode bridge (D1, D2, D3, D4), causing a DC voltage to result across the output buffer capacitor C2. The current that flows in diode pair D1 and D4 (and in the pair D2 and D3) is essentially zero when the diodes are switching on and switching off.

Because the diodes switch on at zero-crossing, diode turn-on losses are much lower than in a hard switching topology – the Vfr voltage overshoot is much lower and sometimes not even detectable. For switch-on power loss the same equation (1) applies as for a hard switching topology, but in a soft switching topology IF is close to zero, so the switch-on losses are nearly zero.

Diode switch-off losses are also much lower because the forward current level is approaching zero when the diode needs to turn off. Again the same equation (3 or 5) applies, but IF is substantially lower than in a hard switching topology. So that makes switch-off losses much lower as well, which can easily be recognized in the diode’s reverse recovery current magnitude in figure 5 – the reverse recovery current only slightly drops below zero.

The main requirement for the diode is that it must be fast enough to keep pace with the switching frequency of the (LLC resonant) power converter.

One component in the energy loss cannot be avoided: conduction loss. Also in soft switching topologies, the conduction loss is given by the second equation.

Because switching losses play a less significant role in soft switching topologies the same (ultrafast/hyperfast) bipolar diodes can be used up too much higher switching frequencies in soft switching topologies than in hard switching topologies.

1200V diodes

Hyperfast bipolar diodes need lifetime control in order to make them switch fast (see also the text box “Lifetime control”) – in principle there’s no fundamental difference between 600V diodes and 1200V diodes. But, compared to 600V diodes, 1200V diodes require a wider drift region/depletion region in order to cope with the 1200V reverse voltage. The consequence of that wider region is that stored charge extraction (at the moment that the diode should turn off) takes longer. In order to make a 1200V diode just as fast as a 600V diode, it needs the lifetime of the charge carriers to be reduced even further. This additional carrier lifetime reduction unfortunately also affects the forward voltage drop of the diode: VF will rise and consequently conduction loss will be higher. It is for this reason that 600V Hyperfast diodes have trr values specified in the order of 20 ns where 1200V Hyperfast diodes have trr values in the order of 60 ns.

Where picking the right balance between conduction loss and switching loss in 600V diodes was already a challenge, it is even more challenging for 1200V diodes.

Leakage and high operating temperature capability

High reverse voltages across a bipolar diode’s terminals will cause a leakage current to flow. Hyperfast diodes need a high concentration of recombination centers (see also the text box “Lifetime control”) in order to give the device its fast switching properties, but unfortunately these recombination centers do also operate as generation centers that contribute to a higher leakage current. Furthermore, when the operating temperature of a Hyperfast diode rises the activity of the generation centers increases, which leads to higher leakage current.

When a Hyperfast diode must be able to operate reliably at high temperatures, it is essential that the leakage current does not rise to a level where the dissipation because of leakage could result in thermal runaway of the device. In order to achieve that a lifetime control method should be used that gives the Hyperfast diode these desired properties. The traditional so-called “Gold-kill” process does usually not allow the resulting Hyperfast diodes to be used above an operating temperature of 150 °C. An enhanced so-called “Platinum-kill” process delivers Hyperfast diodes that can be used up to temperatures of 175 °C and is therefore preferred for manufacturing Hyperfast low-leakage diodes that are capable of operating at high temperature.

Using the right lifetime control and choosing the right balance between conduction losses and switching losses results in 1200V Hyperfast diodes that enable cost-effective and efficient high power/high voltage switched mode power conversion systems.

Conduction loss versus switching loss

In all semiconductor switches (diodes, BJTs, MOSFETs, etc.) two aspects are generally dominant when it comes to power loss: current conduction and switching.

When a semiconductor switch is in the on-state, the current that flows through the device causes a voltage drop across the device. The product of voltage and current is the power loss that occurs in the on-state. On-state conduction losses can be reduced by making the semiconductor switch larger: use more silicon.

Switching losses occur when the ‘charged-state’ of a semiconductor device must be changed because the device is required to go from the off-state to the on-state and vice versa. The amount of charge transport involved determines the energy loss per switching cycle. One way of reducing switching energy loss is by making the semiconductor switch smaller: uses less silicon. A second way to reduce switching energy loss is to select a device type that requires less charge transport for the off- to on-state transition and vice versa. Unfortunately, the switches that require less charge transport commonly exhibit higher on-state losses.

Furthermore, switching energy loss per unit time (that is: power loss) can be reduced by reducing the number of switching cycles per unit time (that is: use a low switching frequency). But in most switching applications the switching frequency or switching frequency range is dictated by external factors, so very often there’s only limited freedom in selecting a switching frequency (range).

A trade-off must be made between conduction loss and switching loss and the goal is to arrive at minimum total power loss. That means that the optimum device must be chosen depending on the application. In an application that switches at a very low frequency a big device that requires a lot of charge transport for switching usually gives the lowest power loss. But when switching frequency goes up, switching losses increase and the optimum device will either be a smaller switch or a switch that requires lower charge transport for switching or a combination of the two. Although one will have to tolerate higher conduction loss, the reduced switching loss will result in minimum total power loss.

Lifetime control

Bipolar semiconductor devices benefit from the phenomenon that current conduction does not occur through only electrons or only holes, but through simultaneous charge transport by both electrons and holes. Additionally, the electron and hole concentrations in the drift layer increase with increasing current density, which results in a better conducting drift layer when the current density in the drift layer increases: conductivity modulation. This phenomenon makes a bipolar structure (e.g. pn-junction diode or BJT) in principle a better-conducting device per unit area than a unipolar device like a MOSFET or a Schottky diode. In other words: with the same amount of silicon you can make a better conducting switch by using bipolar technology.

Disadvantages

Unfortunately, the conductivity modulation phenomenon does also have a disadvantage. When a bipolar device is conducting (that is: in the on-state), a high concentration of charge carriers (electrons and holes) have been injected into the drift layer of the device (that’s what makes the device conduct so well). But, when at a certain moment the bipolar device needs to switch to the off-state, the excess charge carriers in the drift layer must first be removed in one way or another. For that reason, a bipolar cannot switch-off instantaneously. Either one will have to wait until the excess electrons and holes In the drift layer have recombined spontaneously or one will have to extract the excess charge carriers actively. For that reason, in a bipolar diode, that is forced to switch off quickly, a so-called reverse recovery current flows (which extracts the stored charge carriers from the drift layer) before the bipolar diode actually blocks the flow of current.

The amount of charge that can be injected and stored in the drift layer depends on the lifetime of the charge carriers. In ‘normal’ silicon the effective lifetime of charge carriers is in the order of several microseconds to 100’s of microseconds (that would be in ultra-pure silicon without lattice defects). Standard mains rectifier diodes are fabricated using this ‘normal’ silicon; the several microseconds charge carrier lifetime are no limitation for timely spontaneous recombination or charge extraction in a system that switches at 50 or 60 Hz only.

In bipolar diodes that need to be able to switch at much higher switching frequencies, lifetime control is used to reduce the effective lifetime of the charge carriers. Reduced charge carrier lifetime reduces the concentration of charge carriers that can be injected into the drift layer of the diode. That makes the diode less well conducting in the on-state (higher VF at the same current density), but also makes it easier to extract the excess stored charge (simply because it’s less charge) and it speeds-up the spontaneous electron-hole recombination process: the diode switches faster. This also explains why faster diodes (with lower trr) have higher VF.

Lifetime Control in Bipolar Devices

Lifetime control in bipolar devices is a matter of artificially introducing ‘energy levels’ between the valence band and the conduction band in the silicon lattice. This can be done in various ways, but two commonly used methods are so-called “Gold-kill” and “Platinum-kill”. Relatively low concentrations of gold (Au) or platinum (Pt) are diffused into the silicon lattice. The Au or Pt atoms introduce an energy level between the conduction and valence band that functions as a ‘stepping stone’ for excess electrons (in the conduction band) and holes (in the valence band) to recombine. The more of these so-called recombination centers are present in the silicon lattice, the lower the effective lifetime of charge carriers will be.

Reduced charge carrier lifetime increases the VF of a diode because electrons and holes do not only recombine when a diode is required to switch off but also when the diode conducts. A second consequence of the introduction of (Au or Pt) recombination centers is that these centers also operate as so-called generation centers when the diode is in the off-state. This causes a fast Au-killed or Pt-killed diode to have a (much) higher leakage current than a slow “un-killed” diode. At higher operating temperature the leakage current can even cause a substantial part of the total power loss in the diode and may even cause thermal runaway in the end.

However, there is a substantial difference between Au-killed and Pt-killed diodes. Gold is the most effective recombination center, but it is also the ‘best’ generation center. At relatively low temperatures, the leakage current in an Au-killed diode can already be uncomfortably high. Platinum is not as effective as Gold as a recombination center, but it’s also a less effective generation center. Therefore Pt-killed diodes exhibit lower leakage current at the same operating temperature. Where most Au-killed diodes cannot be used at an operating temperature above 150°C, Pt-killed diodes are commonly able to operate at a temperature of 175°C or higher and are therefore a more reliable solution.

About the Authors

Nick Koper works as a Technical Engineer in the R&D Department at WeEn Semiconductors, a semiconductor company that is focused on developing a wide and deep portfolio of industry-leading bipolar power products including thyristors - consisting of silicon controlled rectifiers and triacs -, silicon power diodes, high voltage transistors and silicon carbide diodes.

ChaoChao Shi is a Senior Market Planner at WeEn Semiconductors. She is responsible for taking the initiative of WeEn global Marcom activities, promote the branding of WeEn and arrange quarterly publication of market collateral. She earned her Bachelor's Degree in English at Nanhua University, Chiayi County, Taiwan. She then earned her Master's Degree in Foreign Language and Literature at Yantai University, Shindong China.

Terry Liu is the Product Manager at WeEn Semiconductors. He is primarily responsible for product management, product marketing, business development and product applications of Power device (diodes, transistors, Silicon carbide device, Thyristors, and IGBT). He earned his Bachelor's Degree in Electrical and Electronics Engineering and his Master's Degree in Wireless Communication System at Southeast University, Nanjing, Jiangsu, China.