ABB Northvolt Partnership Expands to Battery Recycling

Through an expanded partnership with Northvolt, ABB will be a leading supplier of power management and electrification solutions for Northvolt’s new Revolt Ett battery recycling facility.

ABB and Northvolt are strengthening the collaboration between the two companies with an agreement for ABB to supply critical electrification infrastructure to Northvolt’s Revolt Ett battery recycling facility.

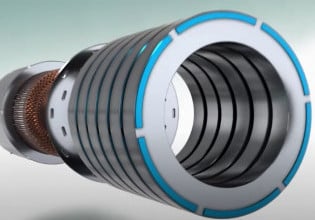

Revolt Ett battery recycling facility to open in 2023. Image used courtesy of ABB

Once complete, the Revolt Ett battery recycling facility will be the largest in the world, with the capacity to eventually process up to 125,000 tons of end-of-life batteries and battery production waste each year.

The recycling facility will be located in Skellefteå, northern Sweden, and provide recycled materials to the Northvolt Ett gigafactory, located at the same site, to produce lithium-ion battery cells.

Battery Materials and Sustainable Production

Founded in 2015, Northvolt aimed to develop high-performance and sustainably manufactured lithium-ion battery cells for the energy and mobility markets.

With the rapid adoption of electric vehicles and the growth of renewable energy production, the demand for rechargeable lithium-ion batteries has accelerated. But to meet growing demand, the battery industry faces significant challenges in sourcing the essential, and sometimes difficult to access, raw materials needed to manufacture high-performance, rechargeable batteries at scale.

Battery development must also be sustainable, preserving and efficiently managing the resources needed for production while minimizing adverse environmental impacts.

Raw materials needed for battery manufacturing. Image used courtesy of Northvolt

Emerging Industry for Battery Recycling

To address these challenges, battery recycling is emerging as a critical industry within the battery manufacturing supply chain to help battery suppliers access the raw materials needed for high-volume battery production while at the same time reducing environmental impacts.

For Northvolt, the company’s goal is to reduce the carbon footprint of its batteries by close to 90% and to source at least 50% of the raw materials needed for battery manufacturing (lithium, nickel, cobalt, and manganese) from recycled materials by 2030.

Currently, it takes about 98 kgCO2e to manufacture a single kilowatt hour (kWh) of battery capacity. Northvolt plans to reduce this to 10 kgCO2e per kWh. Along with recycling, using energy from 100% renewable sources also heavily influences the company’s plans to achieve its sustainability goals.

Once online, the Revolt Ett recycling facility should help the Northvolt Ett gigafactory meet its goals for sourcing battery construction materials from recycled products.

Northvolt Ett brought its first lithium-ion battery production block online in 2022 and plans to establish additional blocks sufficient for an annual production capacity of 60 GWh.

Northvolt lithium-ion battery cells. Image used courtesy of Northvolt

ABB Northvolt Relationship

Per the terms of the agreement, ABB will supply the switchgear and variable speed drives for the Revolt Ett recycling facility to power its operations while meeting energy use and efficiency goals.

Starting in 2017, ABB was a key supplier of electrification equipment for the Northvolt Ett gigafactory. Northvolt recently chose ABB’s Plant Optimization Methodology to help operate their integrated electrification, instrumentation, control, and digitalization (EICD) systems.

ABB Group is also a direct investor in Northvolt through its venture capital arm, ABB Technology Ventures (ATV).