Voltage Regulators for Automotive Designs

The Nano technology leverages advancements in circuit design for high speed and low power, optimizes layout to reduce both parasitic effects and size, and carries out semiconductor processing for maximum yield and reliability.

This article is published by EE Power as part of an exclusive digital content partnership with Bodo’s Power Systems.

To achieve best-in-class performance in power management integrated circuits (ICs), ROHM has developed Nano technology that leverages advancements in circuit design for high speed and low power, optimizes layout to reduce both parasitic effects and size, and carries out semiconductor processing for maximum yield and reliability.

Nano Technology

All three of the above domains contribute to a product portfolio of DC/DC converters, LDOs, and PMICs that provides unmatched performance for automotive needs. The Nano Pulse line consists of single-chip solutions for 48 V electric vehicle (EV) designs. For example, the Nano Energy series reduces quiescent power consumption to achieve unprecedented battery life, while the Nano Cap line eliminates the need for large output capacitors to deliver excellent performance in a compact form factor.

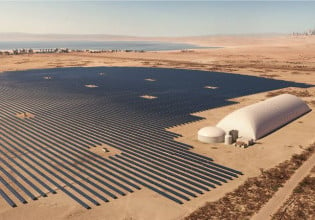

Image used courtesy of Adobe Stock

ROHM’s Nano technology also incorporates many secondary requirements into the primary power management IC. These multifunction chips save space and cost by eliminating the need for supervisory circuits such as watchdog timers, voltage monitors, and even communication bus drivers.

Figure 1. ROHM’s Nano technology. Image used courtesy of Bodo’s Power Systems [PDF]

Figure 2. Multifunction ICs developed using Nano technology. Image used courtesy of Bodo’s Power Systems [PDF]

Nano Pulse for Electric Vehicles

Unlike traditional 12 V lead-acid battery vehicles, hybrid EVs primarily use a 48 V lithium-ion battery to deliver greater efficiency. In both cases, engine control units and peripheral electronics demand lower supply voltages, typically 2.5 to 3.3 V. However, as converting 48 V to 3.3 V is no simple task, conventional solutions typically employ two stages (two ICs). The first stage steps down to an intermediate voltage, such as 12 V, with an easily achievable ratio of 4 to 1. The second stage provides the final output voltage by again dividing down by about 4 to 1. To save space, cost, and efficiency, it is preferable to derive the final 3.3 V output voltage directly from the 48 V source in one step. This difference is shown in the following figure.

Figure 3. Single- and Two-Stage Step-Down Topologies. Image used courtesy of Bodo’s Power Systems [PDF]

To accomplish high ratio single-stage conversion, ROHM’s Nano technology reduces the DC/DC switching minimum on time to an unprecedented 9 ns. This is the shortest switching time in the industry and a breakthrough accomplishment, considering that the typical value is around 120ns. This enables step-down operation from 60 V to 2.5 V using the BD9V100MUF monolithic buck DC/DC converter with integrated MOSFET. The figure below depicts the switching waveform in a representative circuit.

Figure 4. Industry-leading switching speed enables high ratio DC/ DC conversion. Image used courtesy of Bodo’s Power Systems [PDF]

Such a short switching time further enhances performance by minimizing the size of the required inductor. Up to a 70% reduction in overall design size compared to conventional two-stage configurations can be achieved using a single-chip Nano Pulse solution with a small inductor.

Nano Energy for Automotive Subsystems

It may seem counterintuitive that automotive electronics might require ultra-low power consumption, yet several subsystems fall into this category. As shown in the figure below, a variety of automotive modules operate continuously when the vehicle is not running, including clocks, alarms, keyless entry, and infotainment systems. Whether powered by the main vehicle battery or an isolated coin cell, these devices must reliably operate for extended periods of time across a wide range of temperatures.

Figure 5. Energy-sensitive automotive subsystems. Image used courtesy of Bodo’s Power Systems [PDF]

To address these needs, ROHM developed breakthrough Nano Energy technology that decreases standby power consumption. Nano Energy Automotive LDO’s feature a best-in-class quiescent current consumption of only 850nA. Products designed around Nano Energy, such as the BD7xxLx and BD7xxL05 Series, deliver twice the battery drive time of conventional products and greatly improve overall energy efficiency. As shown in the figure below, these devices outperform the competition by a wide margin.

Figure 6. Nano Energy automotive LDO with 850 nA quiescent current. Image used courtesy of Bodo’s Power Systems [PDF]

Nano Cap for Automotive Sensors

Many automotive electronic modules are highly space-constrained, with every component in the system optimized for area and volumetric efficiency. Examples include radar distance units, video cameras, and any number of embedded peripheral sensors for safety and self-driving systems. Each of these subsystems contains a voltage regulator that requires large input and output capacitance for both stability and ripple performance.

ROHM’s Nano Cap technology alleviates this constraint by improving the transient response of the on-chip analog circuits to guarantee linear regulator output stability. This also minimizes parasitic factors related to wiring and amplification, making it possible to reduce the output capacitance to less than 1/10th the size of conventional solutions.

Figure 7. Space-constrained automotive subsystems. Image used courtesy of Bodo’s Power Systems [PDF]

In practical terms, circuits composed of a linear regulator and microcontroller (MCU) typically require a 1 uF capacitor at the output of the linear regulator and 100 nF at the input of the MCU. But with ROHM’s Nano Cap linear regulator technology, designers can achieve stable operation using just one 100 nF capacitor at the MCU side.

Figure 8. Nano Cap technology eliminates the need for large LDO output capacitors. Image used courtesy of Bodo’s Power Systems [PDF]

Eliminating a passive component not only shrinks the PCB area but also greatly simplifies the design load. When every cubic millimeter matters, Nano Cap technology presents an indispensable asset in the automotive designer’s toolbox.

Nano Technology Portfolio

ROHM’s Nano technology portfolio includes Nano Pulse, Nano Energy, and Nano Cap devices that address a variety of needs in the automotive industry by leveraging breakthrough performance along with a dedicated, vertically integrated design and manufacturing process. In addition to qualification under the AEC-Q100 standard, these power management and control ICs are offered in a variety of packages with a host of features.

This article originally appeared in Bodo’s Power Systems [PDF] magazine.