BMS Transformers Feature Safety, Wire Termination Reliability

These BMS transformers address critical concerns of open failure at wire terminations.

In electric vehicles (EVs), reliable and efficient battery management is critical. The battery management system (BMS) transformer is a key component in ensuring the safety, efficiency, and reliability of these systems.

Automotive BMS transformers. Image used courtesy of iNRCORE

iNRCORE, a magnetics and components manufacturer, recently expanded its battery management system transformer line for EV applications. This article will discuss how BMS transformers function and examine the company’s BMS transformers.

What Is a BMS Transformer?

In EVs and energy storage systems, a key component in the battery management system is the BMS transformer.

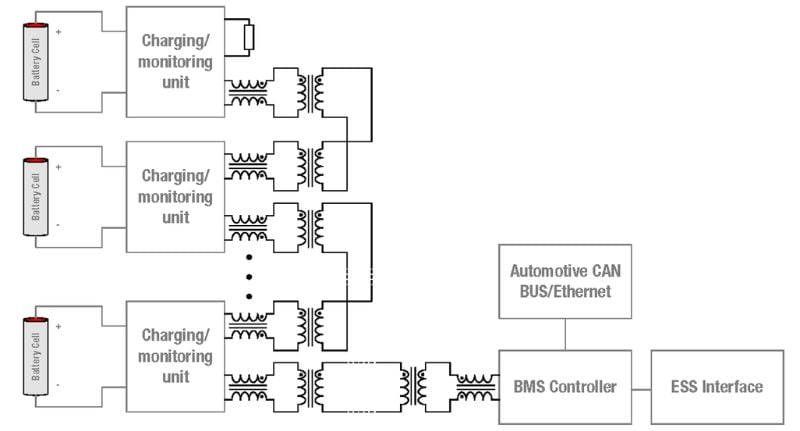

A BMS transformer primarily interfaces between the battery cells and the BMS. The transformer is critical for isolating the BMS from the high voltages typically present in the battery pack, thus ensuring safety and preventing damage to the BMS electronics. This isolation is achieved by magnetically coupling two or more coils, allowing energy transfer without a direct electrical connection and mitigating the risks associated with high-voltage systems, such as short circuits or electric shocks.

A BMS transformer application circuit. Image used courtesy of Würth Elektronik

The BMS transformer performs several key functions. Primarily, it facilitates the measurement of parameters such as voltage, current, and temperature across individual battery cells or modules. The BMS can accurately monitor each cell’s state, ensuring the battery pack’s maximum performance and safety.

The transformer also aids in balancing the charge across cells, a process vital for maintaining the health and efficiency of the battery pack. Uneven charging can lead to reduced capacity and lifespan of the battery, making this balancing act a crucial aspect of battery management.

iNRCORE’s BMS Transformers

iNRCORE previously introduced the RA1055NL, its inaugural BMS transformer with AEC-Q200 qualification, as part of its journey into the EV space. Building on this foundation, iNRCORE has unveiled seven additional BMS transformer models: RA1058NL, RA1059NL, RA1060NL, RA1061NL, RA1062NL, RA1063NL, and RA2055NL.

These models boast diverse features, including varying levels of insulation (functional, basic, and reinforced), creepage distances, and package sizes. Key to these transformers is their focus on resolving a common pain point in BMS applications: open failure at wire termination. iNRCORE addresses this by employing a combination of spot welding and post-soldering processes, enhancing the connections' reliability and robustness.

Moreover, these BMS transformers provide essential safety isolation and effective EMI noise suppression, which is critical for the smooth operation of EV systems. The devices are suitable for various applications, including serial daisy chain and isoSPI, and operate in a temperature range of -40 °C to over +125°C.

Safer Electric Vehicles

As manufacturers continue to innovate in response to the growing demand for EVs, the focus will likely remain on enhancing the performance and reliability of key subsystems, including battery management. The progress in BMS transformer technology is part of a larger narrative in power electronics, where advancements continuously support vehicle performance, battery lifespan, overall user experience, and the sustainability and efficiency of EVs.