Graphene-Copper Delivers High Conductivity, Thermal Resistance

Research in copper-graphene composites could pave the way for significantly more efficient power distribution in industrial equipment, electric vehicles, and more.

The growth of data centers, renewable energy, electric vehicles, and other high-power applications has increased the need for reliable, efficient power distribution. To meet demand, researchers have been exploring ways to make more efficient conductors that exhibit better conductivity regardless of their temperatures to meet demand.

Copper wire. Image used courtesy of U.S. NRC

The development of copper-graphene composite conductors may represent a breakthrough in power distribution. Pacific Northwest National Laboratory researchers have actualized the benefits of graphene in a real-world conductor.

Temperature Coefficient of Resistance and Graphene

The temperature coefficient of resistance (TCR) is a fundamental property of materials that quantifies how their electrical resistance changes with temperature. Represented as a ratio, it describes the change in resistance per degree of temperature change relative to a specified base temperature, usually 20°C.

A positive TCR means resistance increases with temperature, while a negative TCR indicates the opposite. Understanding TCR is crucial in various applications, especially in power distribution, where temperature variations can significantly affect performance and efficiency.

Average TCR ΔR/R in ppm for a temperature range from -55 to 25˚C and from 25 to 125˚C. Image used courtesy of the EEPower Resistor Guide

Materials with a low or stable TCR are preferred in power distribution systems. This is because electrical systems often operate over a range of temperatures, and fluctuations in resistance can lead to inefficiencies, energy losses, and potential overheating. For instance, materials with high TCRs used in power cables may experience resistance increases under high load conditions, leading to additional heat generation. This can reduce the power system’s energy efficiency, accelerate component aging, and increase maintenance costs.

Graphene has become one of the most promising materials for addressing the TCR challenge because the carbon atoms, arranged in a single layer, can form a hexagonal lattice. In this unique one-dimensional structure, graphene exhibits exceptional electrical, thermal, and mechanical properties. For example, whereas pure copper is reported to have a TCR of 0.393% per degree Celsius, graphene exhibits a much lower TCR of 0.207% per degree Celsius.

For this reason, graphene-enhanced composites could operate effectively at higher temperatures without significant losses in conductivity, potentially making energy systems more robust, efficient, and sustainable.

The Copper-Graphene Composite Research

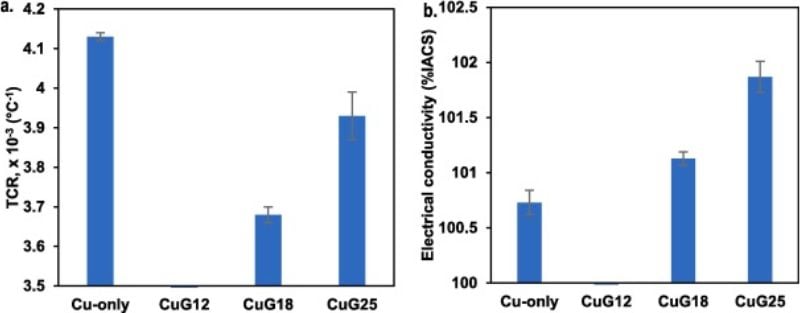

The DOE’s researchers produced copper-graphene composite from C11000 alloys with 18 parts per million graphene deposited via chemical vapor deposition. The patented manufacturing process, dubbed ShAPE, resulted in wires with diameters of 1.5 mm and lengths ranging from 250 to 600 mm. The researchers concluded the presence of graphene, particularly with high defect density, appears to reduce the TCR while retaining low defect density flakes that enhance electrical conductivity.

The copper-graphene composites outperformed pure copper in TCR and conductivity. Image used courtesy of Gwalani et al.

The process resulted in an 11% reduction in TCR and a 0.4% improvement in conductivity compared to conventional C11000. In the same experiment, the team found adding 25 ppm graphene reduced the TCR by nearly 5% and increased electrical conductivity by over 1%.

While a 1% gain in efficiency may seem trivial, when scaled up in applications like electric vehicles, power plants, and data centers, this could save millions of watts of power. The result is a more efficient and sustainable power distribution infrastructure.

A Promising Future for Copper-Graphene

The DOE’s successful production of copper-graphene composites with reduced TCR and enhanced conductivity demonstrates graphene’s enormous potential in numerous high-power applications. From powering more efficient electric vehicles to ensuring the sustainable operation of data centers and renewable energy systems, the research represents a significant step forward in the search for energy efficiency and sustainability.