Breakthroughs in Battery Longevity, Performance and Safety

Recent research in battery technology and materials could lead to more efficient, longer-lasting electric vehicle and storage batteries.

The advancement of battery technology is a critical focus area, where the demand for efficient, reliable, and safe energy storage solutions is at an all-time high. Recently, a slew of research has been helping to push the state of the battery industry forward, presenting improvements in battery technology across the board.

Electric vehicle battery research at Idaho National Laboratory. Image used courtesy of INL

This roundup covers three significant developments demonstrating the depth and diversity of current research in battery technology.

Enhancing Battery Longevity with Soap-like Molecules

Teams from Brown University and Idaho National Laboratory have unearthed a novel approach to improve battery longevity, drawing inspiration from the mechanics of how soap cleans.

Specifically, their research has focused on a new type of electrolyte called localized high-concentration electrolyte. The fundamental principle behind this innovation is the formation of micelle-like structures within the electrolyte, akin to those formed by soap in water. In this context, the solvent in the electrolyte behaves like soap, binding the diluent and the salt to create effective electrolyte structures.

The electrolyte mimics the micelle structures of soap. Image used courtesy of Brown University

Traditional electrolytes in lithium-ion batteries, made of low-concentration salt in a liquid solvent, fall short in effectiveness for metal-based batteries. The innovative localized high-concentration electrolytes, concocted by mixing high concentrations of salt with a solvent and a diluent, improve the flow of the electrolyte, thus maintaining the battery's power.

Lab tests have shown promising results for these electrolytes. By understanding the optimal ratios and concentrations of the three components (salt, solvent, and diluent), the researchers have provided guidelines for making more effective electrolytes. This breakthrough enhances the performance of lithium metal batteries and opens up new design possibilities for high-density batteries.

Innovative Materials for Future Batteries

Swiss Federal Laboratories for Materials Science and Technology researchers recently discovered novel materials for the next generation of batteries.

Their work is particularly relevant for two major applications: electromobility and stationary storage for renewable energy. For electric vehicles, the batteries need to be compact, lightweight, and capable of fast charging. In contrast, stationary storage batteries, used to store energy from renewable sources, prioritize cost-effectiveness.

Researchers from the Empa team. Image used courtesy of Empa

One approach to improving electromobility in batteries involves replacing graphite anodes with pure metallic lithium, which offers significantly higher energy storage. However, this replacement has challenges, such as the formation of dendrites that can short-circuit the battery.

Researchers have explored using solid electrolytes, specifically a refined version of lithium lanthanum zirconium oxide (LLZO), to address this. This material has high ionic conductivity and chemical stability, making it an ideal candidate for solid-state batteries. A manufacturing process has also been developed to produce these solid electrolytes cost-effectively.

Preventing Catastrophic Failure in Lithium-Ion Batteries

The Australian Nuclear Science and Technology Organisation (ANSTO) studied the in situ determination of the surface area and structure of deposited metallic lithium within lithium metal batteries (LMBs).

The study emphasized the challenges faced in developing LMBs, primarily due to forming high-surface-area microstructures at electrode surfaces, leading to safety and performance issues such as rapid capacity fade. The goal was to provide a quantitative understanding of the morphology of metallic lithium growth within these batteries.

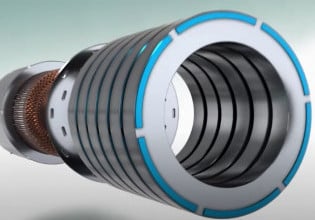

The in-situ cell construction. Image used courtesy of ANSTO

To investigate this, the researchers employed small- and ultra-small-angle neutron scattering (SANS and USANS). These techniques are advantageous for studying the morphology of structures within objects on length scales from 1 nm to 10 μm, and they are sensitive to neutron scattering length density (SLD) inhomogeneities in a sample. SLD inhomogeneities typically arise from elemental and isotopic density variations found at the interface between two phases. This approach allows for studying the complex structures within LIBs and LMBs with high penetration of neutrons, enabling in situ measurements without the need for destructive analysis typical in microscopy studies. Studies using SANS and USANS have been limited in the field.

By employing SANS and USANS, the researchers derived detailed information on the structural development of deposited lithium with precision and less difficulty compared to other techniques like X-ray tomography, microscopy, or gas adsorption. Such insights are essential for addressing the limitations and improving the performance and safety of LMBs.