Opto-Emulators Explained: Exploring Optocoupler Alternatives

Optocouplers have long been an option for designers seeking galvanic isolation for system signals. This article explores alternatives to the technology.

This article is published by EEPower as part of an exclusive digital content partnership with Bodo’s Power Systems.

Optocouplers, also known as photocouplers, opto-isolators, and optical isolators, have long been an option for designers seeking galvanic isolation for their system signals. Since the 1970s, these semiconductor devices have played an important role in providing safety isolation for industrial and automotive end equipment. However, despite significant advancements, their progress in electrical characteristics, high-voltage reliability, and integration capabilities appears limited, prompting designers to explore alternatives.

Technologies like capacitive and magnetic isolation have emerged as alternatives, offering better overall performance compared to optocouplers. Texas Instruments (TI) has invested in silicon dioxide (SiO2)-based digital isolation technology since the early 2000s, providing digital isolator products that offer the same functionality as optocouplers with some distinct advantages.

Bridging the Gap: Introducing Opto-Emulators

Texas Instruments opto-emulators combine the benefits of traditional optocouplers and TI’s SiO2-based isolation technology. Opto-emulators are pin-to-pin compatible with the industry’s most popular optocouplers, facilitating seamless integration into existing designs while providing equivalent signal behavior. These products appear and behave just like optocouplers from a design engineer’s perspective but leverage TI’s SiO2 technology for the isolation barrier. With the barrier effectively blocking high-voltage signals and preventing ground loops—ensuring system safety and stability—you can harness the advantages of SiO2 isolation, which include enhanced electrical characteristics, improved high-voltage reliability, and the potential to integrate additional system functionality. By creating this type of semiconductor product, our goal is to give you the best of both worlds.

Image used courtesy of Bodo’s Power Systems [PDF]

Traditional optocouplers use an LED to transmit digital or analog information across an isolation barrier where a phototransistor detects the signal on the other side, as shown in Figure 1. It is a well-known fact that the LEDs used in optocouplers have an aging or degradation effect over their lifetime. This property is a significant headache to system designers and the number one complaint we hear. Additionally, the insulating material used in an optocoupler ranges from just air to epoxies or mold compounds. Table 1 shows the difference in the isolation strength of an optocoupler vs. an opto-emulator using a SiO2 dielectric.

Figure 1. Typical optocoupler construction. Image used courtesy of Bodo’s Power Systems [PDF]

Table 1. The dielectric strength of various insulating materials

| Insulator Materials | Technology | Dielectric Strength |

| Air | Optocouplers | ~1 VRMS/µm |

| Epoxies | Optocouplers | ~20 VRMS/µm |

| Silica Filled Mold Compounds | Optocouplers | ~100 VRMS/µm |

| SiO2 | Opto-emulators | ~500 VRMS/µm |

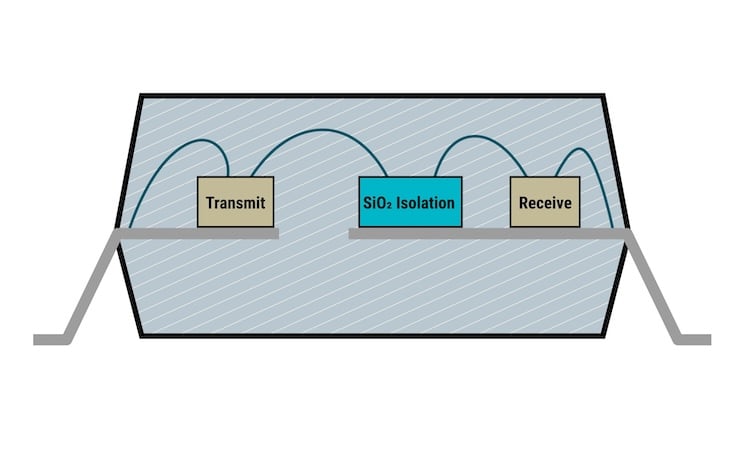

With opto-emulators using an SiO2-based isolation barrier to achieve signal isolation, it’s possible to avoid both of these common optocoupler pitfalls. Figure 2 shows the internal construction of a TI opto-emulator, where the functional behavior of a traditional optocoupler is emulated on the transmit and receive circuits and SiO2 provides the high-voltage isolation.

Figure 2. Construction of a TI digital isolator. Image used courtesy of Bodo’s Power Systems [PDF]

Advantages of Opto-Emulators

By integrating advanced isolation technology, opto-emulators can overcome the limitations associated with traditional optocouplers, enabling superior performance and reliability. Let’s discuss a few of the advantages of opto-emulators:

Lower Power Consumption

Traditional optocouplers require upfront overdesigning to help compensate for the inevitable aging effects of the LED, requiring additional forward current (IF) throughout the design’s lifetime. TI opto-emulators can save as much as 80% on your power budget by offering a much lower IF and supply current.

Improved Common-Mode Transient Immunity

While a common digital optocoupler specifies a common-mode transient immunity (CMTI) of approximately 15 kV/µs, the ISOM8710 has a minimum CMTI of 125 kV/µs, enabling its use in applications with very high common-mode switching noise or high ringing noise.

A Stable and Tight Current Transfer Ratio

Forget the days of paying extra for a tighter current transfer ratio (CTR) range. TI opto-emulators such as the ISOM8110 come standard with a variety of tight CTR ranges that are stable over temperature.

Fast Data Rates

Typical high-speed optocouplers support data rates from 1 Mbps up to 10 Mbps, while the ISOM8710 supports 25 Mbps. This support allows for higher throughput and enables the use of opto-emulators in a variety of high-speed applications.

Bandwidth

The ISOM8110 supports a high bandwidth of 680 kHz, enabling a reduction in the size of mandatory magnetics (inductor and transformer). The wide bandwidth enables improved transient responses for secondary-side regulated flyback converters. The improved transient response allows for a reduction in the size of output capacitors, freeing up board space and reducing overall system cost, especially in high-switching-frequency gallium nitride designs.

Wide Temperature Range

The average optocoupler supports a temperature range from 0°C to +85°C. While some optocouplers support a wider temperature range, that feature comes at an additional cost. TI opto-emulators support a temperature range as wide as –55°C to +125°C as a standard offering and more automotive-qualified devices will be available in 2024.

Reliable Isolation

Opto-emulators have improved high-voltage capabilities, making them suitable for applications demanding reliable isolation. TI opto-emulators leverage SiO2 for the insulating barrier, providing 500 V/µm of isolation, significantly stronger than the air (1 V/µm) used in many optocouplers.

Takeaways of Opto-Emulators

Opto-emulators represent a significant advancement in signal isolation technology, combining the familiarity of optocouplers with the advantages of SiO2-based isolation. These devices empower you to meet the demands of modern systems, ensuring enhanced performance, reliability, and safety. By leveraging opto-emulators, you can optimize your designs and embrace advances in isolation technology.

This article originally appeared in Bodo’s Power Systems [PDF] magazine.

The graphics for Fig 1 & 2 are reversed!