How To Select a Transformer When Designing an Isolated Buck Converter

This article explains how to select a transformer—a pivotal step in designing an isolated buck converter—including parameters to consider, the mathematics to follow, and how the parameters influence the overall circuit.

This article is published by EEPower as part of an exclusive digital content partnership with Bodo’s Power Systems.

This article explains how an isolated buck converter works and how to select a transformer—a pivotal part of designing an isolated buck converter. It discusses which parameters to consider, the mathematics to follow when choosing a transformer, and how they influence the overall circuit.

Image used courtesy of Adobe Stock

How Does an Isolated Buck Converter Work?

An isolated buck topology, as shown in Figure 1, is similar to a generic buck converter. Replacing the inductor in a buck circuit using a transformer results in an isolated buck converter. The transformer’s secondary side has an independent ground.

Figure 1. An isolated buck topology. Image used courtesy of Bodo’s Power Systems [PDF]

The high-side switch (QHS) is on during on-time, and the low-side switch (QLS) is off. The transformer’s magnetizing inductance (LPRI) is charged up. The arrows in Figure 2 show the current flow direction. The primary current increases linearly. The current ramping slope depends on (VIN – VPRI) and LPRI. The secondary side diode, D1, is reverse biased during this time interval and loads current flow from COUT to load.

Figure 2. On period equivalent circuit. Image used courtesy of Bodo’s Power Systems [PDF]

During off-time, QHS is off, and QLS is on. The primary inductor is discharged. The primary current flows from QLS to ground, D1 is forward biased, and the secondary current flows from the second side coil to COUT and to load. COUT is charged up in this time period. (Turning off QHS and turning on QLS cannot change current direction; it can only change the current slope. The positive current decreases until 0 A, then the negative current increases.)

Figure 3. Off-period equivalent circuit. Image used courtesy of Bodo’s Power Systems [PDF]

Which Specifications Influence the Transformer?

Some specifications should be declared and cleared when designing a converter. This will determine which component will be used, especially when choosing a transformer.

- Input voltage range

- Output voltage

- Maximum duty cycle

- Switch frequency

- Output voltage ripple

- Output current

- Output power

Maximum duty cycle (D) is usually assigned in the range of 0.4 to 0.6. The minimum input voltage (VIN_MIN) and maximum duty cycle will determine the primary output voltage (VPRI). Then, the primary output voltage (VPRI) and secondary output voltage (VOUT) will determine the transformer turns ratio.

Output current (IOUT) and output power (POUT) are key parameters that influence transformer selection. Output current determines the thickness of the copper wire, while output power determines which transformer bobbin should be used. The permeability of the bobbin shows how much energy it can store and how much power it can put out. Generally, the DC output current multiplied by a coefficient is assigned to the inductor’s (transformer’s) ripple current. Duty cycle and switch frequency are used to calculate TON time, while VIN, VPRI, and ripple current determine the primary inductance. The assigned coefficient must not be too large or too small since a large coefficient can lead to a large ripple current. A large ripple current may reach half the H-bridge current limit and damage the MOSFET. This will lead to a large ripple voltage on the output capacitor due to its ESR and ESL.

On the contrary, when an extremely small ripple current is needed, we must use a high inductance value inductor (transformer). If the coil has many turns, this will require a bulky bobbin. The large inductance will limit loop bandwidth and reduce the dynamic response index.

Choosing a Transformer

Energy is transmitted to the secondary coil only in TOFF time. The turns ratio can be determined by Equation 1:

\[\frac{V_{OUT}+V_{D}}{V_{PRI}}=\frac{N_{SEC}}{N_{PRI}}\,\,\,(1)\]

Where VD is the secondary diode forward bias voltage. For VPRI, we usually assign a maximum duty cycle of 0.4 to 0.6. The VPRI can be calculated using Equation 2:

\[V_{PRI}=D\times V_{IN\_MIN}\,\,\,(2)\]

Where D is the maximum duty cycle, and VIN_MIN is the minimum input voltage. From Equation 2, we can calculate the turns ratio. In a non-isolated buck converter, the ripple current is the same on both sides of the inductor. We can easily calculate the inductance required using Equation 3.

\[L=\frac{(V_{IN\_MIN}-V_{OUT})\times D}{f\times\Delta I}\,\,\,(3)\]

Where f is the switching frequency, and ΔI is the ripple current. As discussed previously, ripple current equals the DC output current multiplied by a coefficient:

\[\Delta I_{OUT}\times K\,\,\,(4)\]

Where K is the coefficient. But in an isolated buck converter topology, there is a transformer and not an inductor. How do we deal with it when the component is a transformer rather than an inductor? As we know, the current ratio equals the inverse of the turns ratio:

\[IPRI_{TOFF}=I_{SEC}\times\frac{N_{SEC}}{N_{PRI}}\,\,\,(5)\]

Where IPRITOFF is the secondary current converted to a primary current in TOFF time. We should add a transformer’s two-coil current as an equivalent inductor current.

\[ILeq=I_{PRI}+I_{SEC}\times\frac{N_{SEC}}{N_{PRI}}\,\,\,(6)\]

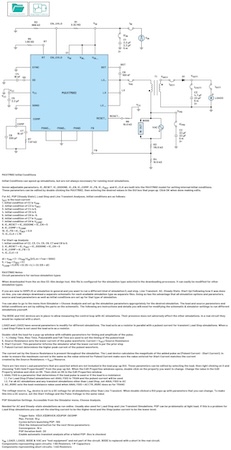

Figure 4. A MAX17682 typical circuit in EE-Sim OASIS, powered by SIMetrix/SIMPLIS. Image used courtesy of Bodo’s Power Systems [PDF]

Where ILeq is the equivalent inductor current. If the transformer has three more windings, then

\[ILeq=I_{PRI}+I_{SEC}\times\frac{N_{SEC}}{N_{PRI}}+I_{THI}\times\frac{N_{THI}}{N_{PRI}}+\cdot\cdot\cdot\,\,\,(7)\]

Is this correct? Let’s see a simulation result based on the MAX17682. Figure 4 shows a MAX17682 circuit, which was drawn in EE-Sim® OASIS, powered by SIMetrix/SIMPLIS. Current probes, labeled IPRI and ISEC1, have been placed at both sides of the transformer.

Figure 5 shows a transient simulation result from the two probes. The two current waveforms were added utilizing Equation 6.

The added current results (red) in a triangle wave behave like the inductor in a non-isolated buck converter. So, the transformer’s primary ΔI can be easily calculated:

\[\Delta I=(I_{PRI}+I_{SEC}\times\frac{N_{SEC}}{N_{PRI}})\times K\,\,\,(8)\]

Usually, we assign a load ripple current that is 0.2 times the DC output current. So, K can be assigned to 0.2 times NSEC/NPRI. At the same time, the primary peak current should be designed less than the switch current limitation, where IPK is:

\[I_{PK}=ILeq_{DC}+\frac{\Delta I}{2}\,\,\,(9)\]

Then, the transformer’s primary inductance can be easily calculated:

\[L_{PRI}=\frac{(V_{IN\_MIN}-V_{PRI})\times D}{f\times\Delta I}\,\,\,(10)\]

Using the turns ratio, primary inductance, output power, output current, and isolation voltage, we can decide which inductor will be used or designed.

Why a Simplified Equation Can Work

Let’s see how we can better understand and apply the equation shown in the MAX17682 data sheet (see Figure 6).

According to the previous discussion, Equation 10 can be rewritten to follow Equation 11 for TOFF time.

\[L_{PRI}=\frac{V_{PRI}\times(1-D)}{f\times\Delta I}\,\,\,(11)\]

Figure 5. A MAX17682 typical circuit simulated current waveform. Image used courtesy of Bodo’s Power Systems [PDF]

Figure 6. A screenshot of the MAX17682 data sheet. Image used courtesy of Bodo’s Power Systems [PDF]

Assuming D is 0.6, if and only if ΔI were 0.4 A, the polynomial (1 – D) and ΔI can be reduced. Then, Equation 11 and the equation from Figure 6 are the same. The equation in the data sheet already selects the primary ripple current. If we assign D as 0.6, the primary ripple current is 0.4 A. In quantity, TOFF duty cycle equals the primary ripple current.

\[\Delta=1-D\,\,\,(12)\]

Ensuring a Faster Design

Using the simplified equation shown in Figure 6, the user ensures a faster design with a primary ripple current that equals the TOFF duty cycle. If you want to modify the primary ripple current or use another parameter, follow this tutorial.

This article originally appeared in Bodo’s Power Systems [PDF] magazine.