Industry-first 1200V SiC FET Offers Higher Power Density

Diodes Incorporated has expanded its silicon carbide product portfolio with the first-ever 1200 V SiC MOSFET in a TO247-4 package.

With the announcement of the DMWS120H100SM4, Diodes Incorporated is expanding its portfolio of silicon carbide (SiC) products to include, according to the company, the first-ever 1200 V SiC MOSFET in a TO247-4 package.

First-ever 1200 V SiC MOSFET in a TO247-4 package. Image used courtesy of Diodes Incorporated

With its compact package and high power density, the N-channel FET will be targeted for use in high-voltage power conversion applications, including electric vehicle chargers, energy storage systems, solar inverters, and industrial motor drives.

For automotive applications, the new FET is AEC-Q101 qualified and manufactured in IATF 16949 certified facilities.

High Power Density

Along with a withstand voltage of 1200 V, the DMWS120H100SM4 can accommodate continuous drain currents (ID) of just over 37 A at 25°C. With heat sinking, the power MOSFET can dissipate up to 208 W and has a low on-resistance (RDS(ON)) of 80 mΩ at a gate threshold voltage (VGS(TH)) of 15 V.

TO274-4 SIC MOSFET pinout. Image used courtesy of Diodes Incorporated

The body of the TO247-4 package is roughly 16 mm x 23.5 mm x 5 mm, offering a compact form factor and high power density for its current rating.

The four-lead package includes a Kelvin-sensing pin that connects to the source to assist with switching performance. The separate Kelvin pin allows for the source voltage to be sensed by the controller through a control line separate from the load-carrying terminal. This provides a more accurate signal measurement at the source pin and allows for better switch control.

As is typical with wide bandgap materials like silicon carbide, a high gate voltage is required to fully open the conduction channel for the best performance and efficiency. To get below 100 mΩ of on-resistance, the gate-source voltage needs to exceed 12 V.

VGS needed to achieve optimal performance. Image used courtesy of Diodes Incorporated

Fast Switching Response

Many designers are looking to SiC MOSFET technologies because of their superior performance in fast switching and high-frequency circuits. In power conversion circuits, a higher switching frequency allows for smaller components, which translates to a more compact design.

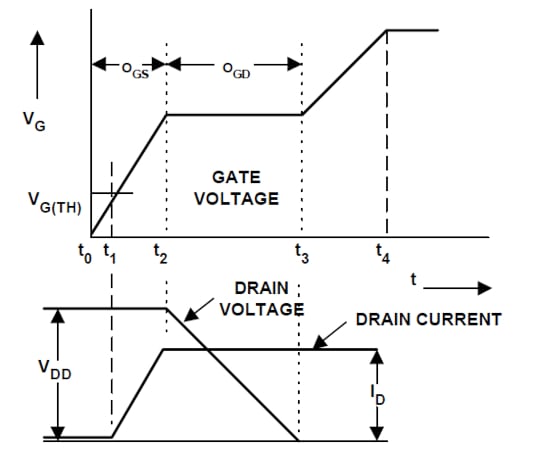

Regarding dynamic response and switching speed, the DMWS120H100SM4 has a turn-on rise time of ~ 20 ns and a turn-off fall time of about ~ 5 ns. The total specified gate charge (QG) for the switch is 52 nC, an important parameter for assessing response time. The total gate charge is the sum of the gate-source charge (QGS) and gate-drain charge (QGD) and helps define the transient response of the FET to an applied gate voltage.

Gate charge impacts MOSFET turn-on time. Image used courtesy of Infineon

Power Inverter and e-Mobility Applications

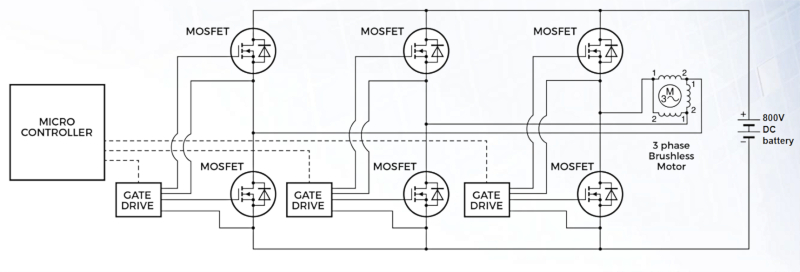

With its high withstand voltage, the DMWS120H100SM4 is suitable for electric vehicle traction inverter applications running off an 800 V battery bus or similar power inverter applications in energy storage or solar power generation systems. Six power FETs can be used to construct a three-phase inverter using three half-bridge circuits.

The power density of the small TO247-4 package allows for a more compact circuit design which translates to a smaller, lighter, and potentially less expensive form factor. For electric vehicles and other e-mobility applications, less weight means longer ranges, smaller battery packs, and faster charging times.

Three-phase power inverter application. Image used courtesy of Diodes Incorporated