Fluke Introduces Enhanced Tools for EV Charging, Solar Testing

Fluke has launched its line of electrical instruments for EVs and renewable energy technology. What problems do the new products solve?

Electric vehicles (EVs) and photovoltaics (PVs) represent a pivotal shift towards sustainable energy and transportation, offering reduced emissions and reliance on fossil fuels. As the demand for EVs rises, ensuring a robust charging infrastructure becomes paramount. However, the maintenance of charging stations and solar panels poses a significant barrier to widespread EV adoption. Streamlining charging station upkeep is crucial to facilitating seamless EV integration into daily life.

Fluke has launched a new line of electrical instruments for EVs and renewable energy technology. What problems do the products solve?

Fluke charging station tester. Image used courtesy of Fluke

EV Charging Infrastructure Roadblock

As the number of EV drivers increases significantly, a pressing concern emerges regarding the charging infrastructure and the dependability of EV charging stations.

Reliability and customer satisfaction are swiftly rising to the forefront of EV owners' priorities, and a notable grievance among many EV users is the frustrating scenario of charging station inoperability (or the lack thereof). This predicament intensifies the phenomenon of EV range anxiety, wherein drivers worry over insufficient battery reserves to reach their destination or at least the next compatible charging facility.

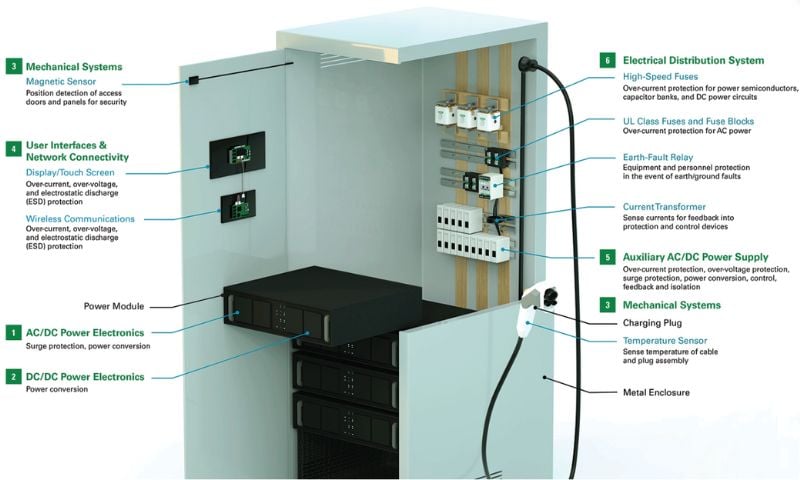

Parts of a DC charging station. Image courtesy of Charged

The reliability of the EV charging station relies on a variety of factors, including the performance of the EV charger and the uptime and upkeep of other interconnected EV assets. EV charging stations typically include power distribution units, charging cables, connectors, and control systems. The charging process involves converting AC power from the grid into DC power suitable for EV batteries through power electronics like rectifiers and inverters. Potential issues in charging stations include power supply fluctuations, faulty connectors or cables, software malfunctions, and communication errors between the station and the EV. Similar issues exist with PVs, also.

A standard preventive maintenance procedure for an EV charger involves cleaning the cables, connectors, and filters, followed by operational checks. Finally, assessing the charger's functionality necessitates connecting an EV to verify its operation. By implementing smarter and quicker maintenance protocols, EV manufacturers can mitigate downtime, improve user experience, and accelerate the transition to electric mobility.

Fluke's Breakthrough Solutions for Electric Vehicles and Solar Panels

Fluke’s FEV350 analyzer for AC EV charging stations offers engineers various safe and efficient testing options, including protective earthing (PE) pre-tests, visual inspections, RCD trip tests, and automated control pilot simulations.

The kit features Type 1 and Type 2 connectors and is tailored for mode 3 AC charging station assessment. Serving as an electric vehicle emulator, it initiates charging cycles and activates voltage and current output for thorough testing. Capable of simulating control pilot (Earth) and PE (Earth Fault) errors, it provides phase indication via three LED lamps for voltage presence verification. With the FEV300, troubleshooting charging stations becomes more efficient, and no need to bring an electric vehicle for testing as the adapter seamlessly replicates one during performance and maintenance checks.

Fluke’s SMFT-1000 PV testing kit. Image used courtesy of Fluke

Additionally, Fluke will announce the SMFT-1000 PV tester, which facilitates performance analysis and I-V curve tracing for photovoltaic systems, meeting IEC 62446-1 standards. Tailored for photovoltaic experts engaged in the installation, commissioning, and upkeep of systems operating at or below 1000 V DC, the SMFT-1000 offers a comprehensive PV testing solution adhering to IEC 62446-1 standards. Leveraging Fluke's TruTest Software, measurement data gathered during solar site installation and commissioning tests can be seamlessly imported, managed, and analyzed, streamlining reporting processes without needing a laptop onsite.

Powering a Better Tomorrow

With cutting-edge tools like Fluke's FEV350 analyzer and SMFT-1000 multifunction PV tester, the industry is poised for enhanced reliability and efficiency. These advancements not only ensure safer and more functional charging stations but also lay the groundwork for a sustainable transportation ecosystem. As EV adoption accelerates globally, such developments promise to accelerate the way people power their vehicles, driving toward a cleaner, greener, and more accessible future.