Used Wind Turbine Blades: Recycle, Reuse, or Redesign?

While wind power is the leading renewable energy generator in the United States, wind turbine disposal is wasteful and contributes to air and soil pollution. Experts are considering options for improving recycling and making more eco-friendly blades.

Wind turbine blade disposal and recycling presents a significant challenge for the renewable energy industry. The materials constructing these blades, typically fiberglass or carbon-fiber reinforced plastics, are durable and resilient, making them hard to recycle using conventional methods.

Decommissioned wind turbine blades being prepared for recycling. Image used courtesy of Department of Energy

Over the next decade, the global annual disposal of turbine blades could reach 200,000 tons. This estimation does not even encompass the newer, taller, and higher-capacity turbine versions.

Existing disposal methods, incineration or landfill, have environmental drawbacks. Incineration generates air pollution, and fiberglass and carbon fiber products are not biodegradable and will stay in the landfill forever.

Identifying alternative disposal methods for turbine blades is crucial to sustaining the overall efficacy of wind power.

Wind Turbine Blades—Durable to a Fault

Most wind turbines feature towering structures with extensive fiberglass blades, some stretching over half the length of a football field. They are specifically designed to endure extreme and turbulent wind conditions. The durability helps increase the lifespan of wind turbines.

Wind turbines have an estimated lifespan of 25 years, but recent data indicates a decrease in turbine decommissioning over the last three years in both Europe and the U.S. This trend suggests that turbines might have the potential to endure longer than originally projected.

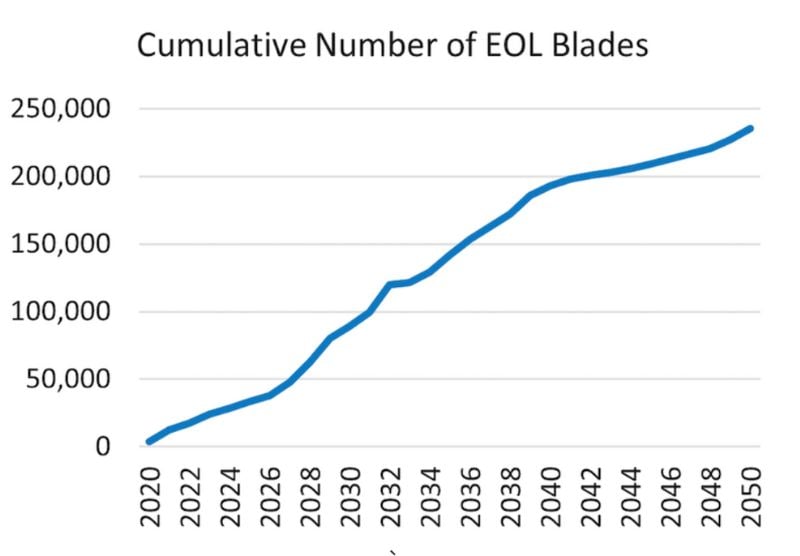

Unfortunately, while this is positive for alleviating immediate concerns about addressing waste disposal issues for turbine blades, the underlying problems still exist. A significant portion of a turbine can be recycled or repurposed for use in other wind farms. However, experts predict the U.S. will grapple with disposing of over 720,000 tons of blade material in the next two decades.

Projected accumulation of end-of-life wind turbine blades over the next two decades. Image used courtesy of Department of Energy

The limited avenues available for recycling or discarding turbine blades result in costly procedures. As a result, most blades either end up in landfills or undergo incineration at the end of their life cycle.

Options for End-of-Life Wind Turbine Blades

Considerable research efforts focus on blade recycling. A major challenge lies in the separation of polymers from the binding resin. The predominant recycling methods are either subjecting them to heat in an oxygen-depleted setting (pyrolysis) or utilizing a solvent to isolate the resin (solvolysis). However, both techniques yield fibers that possess reduced strength compared to new ones and are costlier to produce.

Carbon Rivers, an R&D company in Tennessee, has developed a process for using pyrolysis to retrieve pure, undamaged fiberglass from retired wind turbine blades. This material can be used in new products or upcycled to new-age turbines that would be easier to recycle. The U.S. Department of Energy is funding the project.

Another approach is to redesign turbines with thermoplastic polymers, a type of plastic pliable with heat. Unlike the current thermoset polymers, these thermoplastics would offer easier repairability and could be transformed into new blades more conveniently. Additionally, there's the potential for on-site manufacturing to circumvent transportation requirements.

Recyclable wind turbine blade in production. Image used courtesy of NREL

Options for reusing end-of-life turbine blades include animal-feeding troughs, bus shelters, farm partitions, construction materials for housing, public furniture, thermal insulation, and wave attenuators. There is also the opportunity for reuse in roofing and building foundations, which could reduce environmental impacts within the built environment.

Discovering solutions for recycling or repurposing existing wind turbines could offer valuable insights that extend beyond the renewable energy sector. Such advancements could pave the way for similar approaches for decommissioned boats or planes, which utilize fiber-reinforced materials in their construction. This cross-industry application of recycling and repurposing techniques could significantly address the challenges for end-of-life management for various structures made with similar composite materials.