MIT Researchers Look to Cement Supercapacitors for Energy Storage

Using materials that have been around for ages, MIT researchers have designed a new form of supercapacitor. This article will examine supercapacitors, the challenges surrounding them, and the research from MIT.

With renewable energy gaining significant momentum, the need for better, more sustainable forms of energy storage has become paramount. Instead of traditional batteries and supercapacitors made from rare earth materials, researchers are investigating how to take common and abundant materials and use them for storage.

MIT researchers have discovered a form of supercapacitor made from common materials like cement.

What Is a Supercapacitor?

A supercapacitor is energy storage that exists somewhere in between traditional battery technology and conventional capacitors.

At its core, a supercapacitor consists of two electrodes immersed in an electrolyte, separated by a thin insulating membrane. Unlike batteries, which store energy through chemical reactions, supercapacitors store energy through the physical separation of electrical charges. When voltage is applied, positive and negative charges accumulate on the surfaces of the electrodes, creating an electric double layer. This double layer acts as the energy storage mechanism, allowing supercapacitors to charge and discharge rapidly.

A cylindrical supercapacitor (A) and a parallel plate supercapacitor (B). Image used courtesy of DigiKey

This ability to charge and discharge at exceptionally high rates is one of the standout features of supercapacitors. They can often go from fully charged to fully discharged in seconds or minutes, making them ideal for applications that require quick bursts of energy. However, their energy density, or the amount of energy stored per unit volume, is generally lower than batteries, so they store less total energy.

Unlike traditional batteries, supercapacitors can rapidly charge and discharge, making them particularly suited for bridging the gap between the intermittent nature of renewable energy. By storing energy when it's abundant and releasing it when needed, supercapacitors can ensure a stable and continuous energy supply, facilitating a greater shift to renewable energy.

Supercapacitor Challenges

While supercapacitors have the potential to significantly impact the future of energy storage systems, there are still challenges around the technology that need to be solved. One such challenge is how to develop more affordable supercapacitors.

Traditional supercapacitors often require expensive materials to build, driving the cost of the components up. For example, activated carbon, often used in the electrodes, must be highly purified and processed to achieve the necessary surface area and porosity. Some supercapacitors also use precious metals or other expensive materials as conductive agents. The dependence on these materials drives up the cost of supercapacitors and has adverse sustainability impacts.

Additionally, supercapacitors are made expensive due to the manufacturing process. Supercapacitors often require a specific design to achieve high capacitance, rapid charging and discharging, and long cycle life. This includes using specialized separators, electrolytes, and other components that must be carefully selected and optimized. Achieving these behaviors in practice often involves a specialized manufacturing process that requires precise control over material properties, structure, and composition.

MIT Research

Recently, a team of MIT researchers launched a study to address some challenges facing the design and manufacturing of traditional supercapacitors. To do this, the team sought to make a supercapacitor from two of the most abundant materials on earth: cement and carbon black.

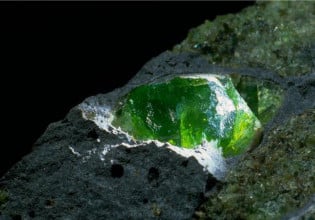

The cement-based supercapacitor. Image used courtesy of Chanut, et al.

The team created a cement-based material with a high internal surface area by introducing carbon black into a concrete mixture with cement powder and water. As the cement hardened, the carbon migrated into spaces within it, forming wire-like structures within the cement. These formations resulted in the development of an extremely large surface area within a small volume, essential for a supercapacitor's function. As described in the research paper, the material was then soaked in a standard electrolyte to introduce charged particles into the substance.

As part of the research, the team discovered a trade-off between the storage capacity of the material and its structural strength. Specifically, more carbon black allows for greater energy storage but decreased strength. The team found that the optimal mix for structural applications is around 10% carbon black. With this mix, the team envisions a future where the very structure of a home or building could be used as a means of energy storage, making renewable energy more affordable and accessible to the masses.

_and_a_parallel_plate_supercapacitor_(B).jpg)