Siemens Rolls Out Multi-Discipline Simulation Tool for EV Designs

The software solution can predict e-machine performance, including axial flux electric drive units.

Siemens’ new software tool, Simcenter E-Machine Design, allows motor designers to perform complex simulations for various motor types, streamlining the design process with a template-driven interface, making it more efficient and less time-consuming than starting from scratch.

Simcenter E-Machine Design automates various modifications to design parameters, updates the simulation model, and reviews the result—allowing users to assess the design tradeoffs. The software creates hundreds of runs without user intervention using associative integration of CAD geometry and simulation modeling.

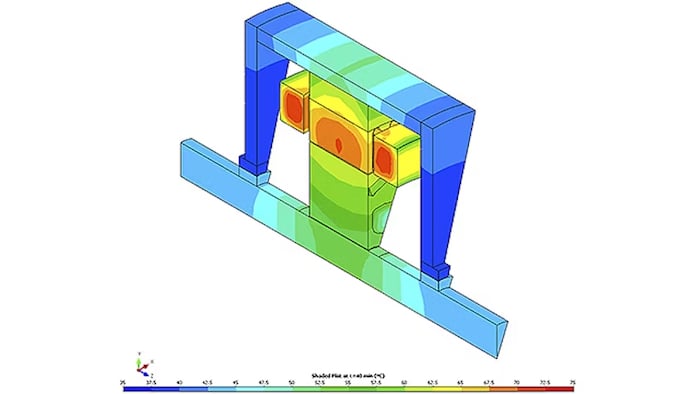

Simcenter E-Machine Design can help electric vehicle manufacturers predict e-machine performance, including that of axial flux electric drive units. Image used courtesy of Siemens

Siemens Releases Simulation Tool

One of the software’s key features is its flexibility in electromagnetic analysis methods, allowing engineers to tailor their approach for higher accuracy and efficiency. It also includes built-in templates for various motor types, including axial flux motors, essential in electric vehicles due to their high power density and compact size.

An example of motor thermal analysis in E-Machine Design. Image used courtesy of Siemens

The software includes integrated magneto-thermal simulations, a resource that can identify potential design issues early in the process, particularly thermal management problems that commonly arise in high-power-density motors. The platform integrates optimization tools and other Simcenter applications to enhance collaborative engineering efforts.

Simcenter E-Machine Design also facilitates a more sustainable approach to motor development. The software lowers material waste and energy consumption during the design phase by reducing the need for physical prototypes. These shorter development cycles can accelerate the time to market for new motor designs while advancing more efficient and quieter electric motors.

Axial Flux Motor Testing Challenges

Axial flux motors are a unique type of motor in which the magnetic flux flows parallel to the motor’s axis. This configuration contrasts with the more common radial flux motors, where the flux moves perpendicularly to the axis. The axial design enables a more compact and lightweight motor, increasing power density, which is crucial for extending the range and efficiency of EVs.

The core advantage of axial flux motors lies in their ability to provide a high torque-to-weight ratio. Compared to radial flux motors, axial flux motors leverage the motor’s magnetic flux and geometry to increase the diameter and shorten the axial length. Consequently, axial flux motors can produce more torque for the same input power, making them highly suitable for applications where space and weight are critical constraints, such as electric vehicles.

Radial vs. axial motor. Screenshot used courtesy of Lesics

However, the transition to axial flux technology presents significant engineering challenges, primarily related to heat management and optimal air gap maintenance. These motors’ compact size and high power density increase heat generation within a confined space, necessitating advanced cooling solutions to prevent overheating and ensure reliable operation. Effective heat dissipation is critical since excessive temperatures can degrade the motor’s components, reducing efficiency and lifespan.

Moreover, the air gap—the space between the rotating and stationary parts of the motor—must be precisely controlled for efficient operation. In axial flux motors, developers may find it challenging to minimize air gaps because of the motor’s design and the forces exerted during operation. Any inconsistency in the air gap can lead to uneven magnetic forces, resulting in vibrations, noise, and reduced efficiency.

Automated Simulation Streamlines Early Development

Simulation tools, like Siemens’ new Simcenter E-Machine Design software, can be useful assets for engineers addressing the challenges of axial flux motors.

Engineers can employ analytical modeling and parameterized templates with the software to fast-track early development. For more complex analyses, such as thermal interactions, users can easily turn to 3D design with Finite Element Analysis simulations. Designers can further analyze acoustics and mechanical motion by transferring electromagnetic loads from Simcenter E-Machine to Simcenter 3D software.

The tool also includes a smart virtual sensor to “simulate the unmeasurable,” according to Siemens. This feature allows a physical test team to place virtual sensors in areas where physical sensors cannot be placed because of complex geometries or hard-to-reach locations. A reduced order model with the virtual sensors then run in real time alongside the physical test.

In this way, the platform brings thermal and electromagnetic simulation into one solution, negating the need for physical prototyping.

_manufacturers..jpg)