Are Coffee Grounds the Answer to Lithium Constraints?

Researchers from Kazakhstan and South Korea may have found a solution to lithium limitations by using spent coffee grounds in sodium-ion anodes.

The unequal distribution of lithium sources worldwide has long concerned battery manufacturers and researchers. In response, scientists have identified sodium-ion batteries (SIBs) as a viable alternative due to the availability of their eco-friendly electrode materials. However, synthesizing an electrode material offering the best electrochemical performance remains a challenge.

Sodium-ion batteries made with coffee grounds improved energy storage. Image used courtesy of Adobe Stock and Pexels

Recently, researchers from Kazakhstan and South Korea synthesized P-doped hard carbon using coffee grounds and the doping agent H3PO4. The results could have significant implications in advancing sodium-ion batteries.

Hard Carbon Challenges

Hard carbon (HC) stands as a prominent candidate for anode materials in sodium-ion batteries, largely because of compelling attributes such as low cost, low operating voltage, and high capacity potential.

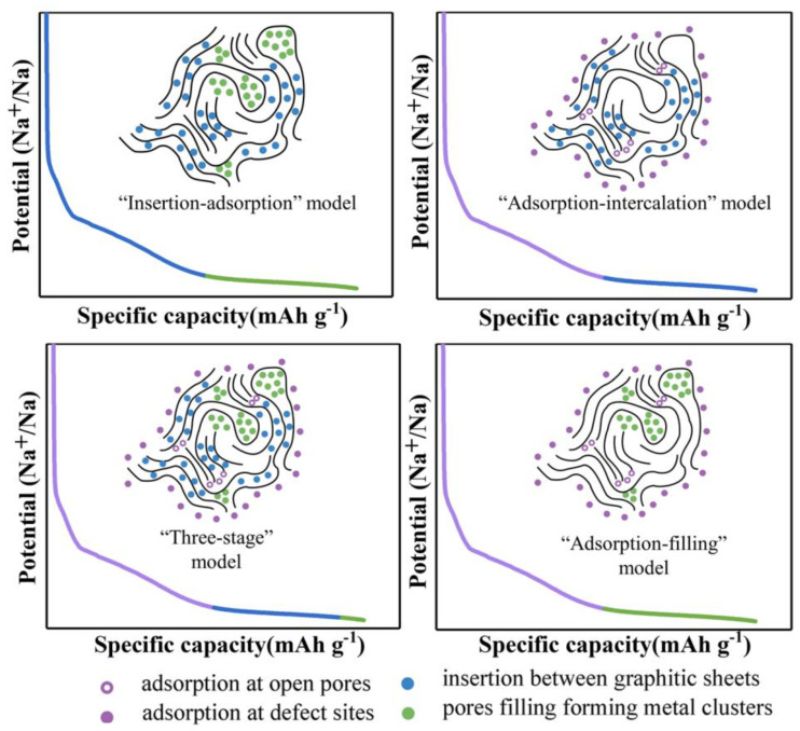

This form of carbon is distinguished by its disordered structure, significantly different from the well-organized graphite layers found in traditional lithium-ion battery anodes. HC's amorphous nature contributes to its ability to intercalate sodium ions, a process critical for battery operation. Unlike graphite, which offers well-defined paths for lithium-ion insertion, HC's irregular structure provides a unique environment for sodium-ion storage, aligning with the larger ionic radius of sodium compared to lithium.

For different mechanisms of sodium storage in hard carbon. Image used courtesy of Zhang et al.

In general, the transition toward SIBs is largely inspired by the abundant availability of sodium, which presents a cost-effective and accessible alternative to lithium, especially given the geographical concentration and limited supply of lithium resources. However, the application of HC in SIBs has its challenges.

One significant hurdle is the low initial Coulombic efficiency (ICE), a measure of the reversible charge capacity of the battery in its first cycle. A low ICE indicates a higher loss of capacity at the outset, which is undesirable for battery performance. Additionally, HC faces issues with rate performance, referring to the battery's ability to charge and discharge at high speeds. The intricate and disordered structure of HC, while beneficial for sodium-ion storage, can impede the rapid movement of ions, leading to slower charge and discharge rates.

Battery Research Uses Coffee as an Answer

To solve the challenges facing the use of HC in SIBs, researchers from Kazakhstan and South Korea innovatively turned to used coffee grounds as a sustainable and cost-effective precursor for HC. Their method involved doping HC with phosphorus to enhance its electrochemical performance, utilizing phosphoric acid (H3PO4) as the dopant. This approach aimed to tackle the inherent issues of low initial Coulombic efficiency and subpar rate performance associated with undoped HC.

ICE for electrodes with HC doped with 2M H3PO4. Image courtesy of Kailbek et al.

The process began with the preparation of the precursor material. Coffee grounds were first acid-washed to remove impurities and then mixed with varying concentrations of H3PO4. Finally, they were carbonized at 1,300°C under an inert atmosphere. This high-temperature treatment facilitated the formation of phosphorus-doped HC with a unique honeycomb structure characterized by numerous open cavities that support efficient ion transmission and electrolyte penetration.

Ultimately, the optimal concentration of H3PO4 was determined to be 2 M, which yielded a phosphorus-doped HC (HCG-1300-2) demonstrating superior electrochemical properties. The resultant material showcased a remarkable specific capacity of 341 mAh g−1 at a current density of 20 mA g−1, coupled with an ICE of 83%. Such performance metrics are attributed to the effective incorporation of phosphorus, which increased the interlayer spacing and introduced more defects and pores into the carbon structure. These modifications facilitated the diffusion of sodium ions and enhanced the material's ability to intercalate them, leading to improved energy storage capabilities.

Overall Impact on Battery Manufacturing

The results of the team’s study could have major implications for the future of the battery manufacturing industry. By offering a high-performing solution to the challenges of hard carbon in SIBs while leveraging the 18 million tons of annual coffee waste to their advantage, the research is a major step in the right direction for sustainability.