Power Innovation for Electric Vehicles: What to Expect in 2024

A look forward to some of the 2024 power product and innovation trends that will impact the design of electric vehicle powertrains, battery systems, and vehicle charging infrastructure.

In 2023, the common themes for electric vehicle (EV) power systems and component designers were power density and efficiency. These are critical attributes for electronic original equipment manufacturers (e-OEMs) tasked with developing EV platforms capable of driving farther, charging faster and more conveniently, and that are accessible at affordable price points.

What’s coming in 2024 in electric vehicle technology? Image used courtesy of Adobe Stock

What can we expect in 2024 for electric vehicles?

Electric Powertrain Innovations

With the traction inverter and electric motor at its heart, the EV powertrain converts stored energy in the battery pack to the mechanical energy that propels the vehicle forward.

Silicon carbide (SiC) and other wide bandgap technologies will continue to be popular for supporting higher voltage powertrain buses designed for more efficiency and to reduce I2R transmission losses. SiC-based power conversion circuits can also support higher power densities with lower on resistances (RDS(ON)) for better efficiency and the ability to operate reliably at elevated temperatures. This means less weight per unit of power, which translates to longer ranges and smaller battery packs that are less expensive and easier to charge.

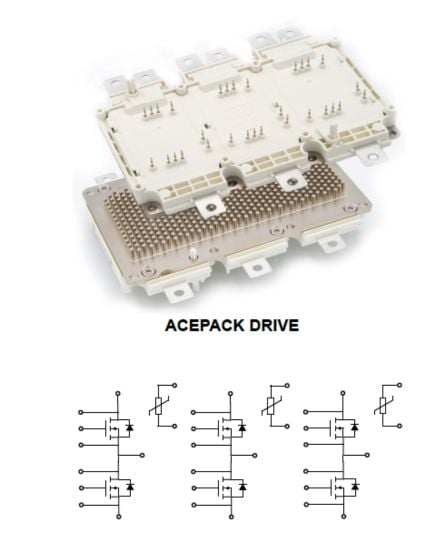

Packaging innovations (like wafer-level chip scale packaging and bare die) and module integrations that reduce solution size and weight will continue to evolve with power density in mind. In addition to saving space, fully tested and pre-configured bridge power modules (2, 4, and 6-pack) can simplify designs and lower costs by reducing BOM (Bill of Materials) counts and simplifying supply chains.

ACEPACK DRIVE power module. Image used courtesy of STMicroelectronics

However, integrated modules do not offer the flexibility of “roll-your-own” designs, so high-end vehicle applications with fewer cost constraints will allow designers to construct traction inverter circuits and other power conversion blocks using discrete power components optimized to the specific performance goals of the vehicle, such as range, charge time, or cost.

The EV powertrain and traction inverter market is large and growing, so along with SiC, power device manufacturers will also target these high-performance applications with gallium nitride (GaN) solutions. GaN circuits can operate at very high frequencies that allow for more compact designs but must demonstrate the ability to operate at increasingly higher powertrain bus voltages.

Wide Bandgap Device Supply Agreements

For 2024, we can expect e-OEMS and Tier 1 suppliers to continue to pursue long-term supply agreements, but caution will be required on both sides as market dynamics can shift quickly. Government support aside, there have already been signs of weakening demand for EVs by consumers, and long-term agreements could represent a financial hazard for suppliers and manufacturers.

EVs are still a relatively new technology, and adoption will not be linear. It is easy to underestimate the vast challenges of restructuring an industry as large as the global automobile industry around a still fundamentally new electric powertrain technology that will replace the internal combustion engine, an incumbent solution that has been used for over a century.

Improvements to EV Battery Systems

For 2024, we can expect battery system innovation to advance on all fronts to improve energy storage density, safety, and cost.

Advancements will include improvements to existing lithium-ion battery technologies and research into new technologies like solid-state batteries that promise even higher energy densities. In 2023, researchers explored the use of alternate anode materials to improve energy storage capacity, while others developed low-cost cathode construction techniques designed to reduce battery costs. This innovation will continue through 2024 and beyond.

IMMERSIO Cell-to-Pack (CTP) EV battery pack. Image used courtesy of XING Mobility

Battery performance is about getting the most from the technologies that already exist. Battery management systems and techniques will continue to evolve, leveraging advanced cell monitoring, software, and processing capabilities like artificial intelligence and machine learning. This allows for a better understanding of battery performance, so operating capabilities (energy capacity, charge times, and power) can be safely expanded.

Innovations impacting battery performance include constructing battery packs from individual cells and managing battery thermal properties.

For challenging technologies like batteries, progress is often incremental, and any 12-month period is not long enough to achieve significant breakthroughs, but progress across multiple axes over extended periods will continue to push battery capabilities forward.

Vehicle Charging

Providing reliable, affordable, and safe access to chargers, particularly Level 3 fast chargers, will drive much of the power system innovation for EV charging in 2024. Public policy and government programs will continue to provide tailwinds, at least in the near term, for DC fast charger deployments.

As EV powertrain buses move to 800 V and higher, fast chargers will be improved to operate at higher voltages and power levels to recharge batteries faster and more efficiently. This will drive further development of wide bandgap (SiC, GaN) components and rectifier modules that can operate at elevated voltages, higher power densities, and with greater conversion efficiency.

Kempower Satellite DC fast chargers. Image used courtesy of Kempower

Level 1 and 2 charger developments will also focus on higher power capacities to deliver shorter charge times and lower price points to support broader deployment in urban, suburban, and residential settings. In addition to wide bandgap technologies, these applications may also benefit from advances in silicon MOSFET and IGBT devices that can accommodate more aggressive cost targets.

Within the vehicle itself, the onboard charger (OBC) will continue to be a critical power conversion circuit block to convert AC power from Level 1 and 2 chargers to replenish DC batteries. GaN and SiC power conversion solutions will compete head-to-head on power density and conversion efficiency to reduce vehicle charge times and extend ranges while minimizing costs.

While the OBC remains a critical functional block of the modern EV, looking out a bit further, it is relatively easy to imagine a future where all levels and modes of EV charging migrate to higher voltage DC charging. This would eliminate the need for complex and expensive OBC circuits within the EV.

As power conversion technology evolves to support higher voltages and power levels and at more affordable price points, we may see DC charging topologies migrate to urban public access and even residential charging applications. They may not operate at the power levels of AC mains connected DC fast chargers but with a common charge interface that simplifies EV design and reduces costs.

_EV_battery_pack_1.jpg)