ROHM Unveils 4th-Gen 1200V SiC MOSFETs for Automotive Powertrain Systems

ROHM hightlights its 4th Generation 1200V SiC MOSFETs optimized for automotive powertrain systems, including the main drive inverter, as well as power supplies for industrial equipment.

ROHM announces the cutting-edge 4th Generation 1200V SiC MOSFETs optimized for automotive powertrain systems, including the main drive inverter, as well as power supplies for industrial equipment.

In recent years, the proliferation of next-generation electric vehicles (xEVs) has been accelerating the development of smaller, lighter, and more efficient electrical systems. In particular, improving efficiency while decreasing the size of the main inverter that plays a central role in the drive system remains among the most important challenges, requiring further advancements in power devices.

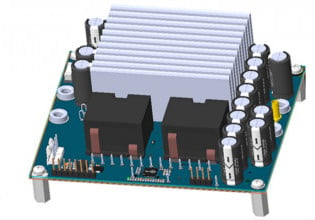

Image courtesy of ROHM

The capacity of the onboard battery is increasing to improve the cruising range of EVs. And in conjunction with this, the use of higher voltage batteries (800V) is progressing to meet the demand for shorter charging times.

To solve these various challenges, designers urgently need SiC power devices capable of providing high withstand voltage with low losses. ROHM, a pioneer in SiC, began mass-producing SiC MOSFETs ahead of the industry in 2010. From early on, ROHM has strengthened its considerable lineup to include AEC-Q101 qualified products allowing the company to hold a large market share for automotive on-board chargers (OBC).

For power semiconductors there is often a trade-off relationship between lower ON resistance and short-circuit withstand time, which is required to strike a balance for achieving lower power losses in SiC MOSFETs. ROHM was able to successfully improve this trade-off relationship and reduce ON resistance per unit area by 40% over conventional products without sacrificing short-circuit withstand time by further improving an original double trench structure. In addition, significantly reducing the parasitic capacitance (which is a problem during switching) makes it possible to achieve 50% lower switching loss over our previous generation of SiC MOSFETs.

As a result, ROHM’s new 4th Generation SiC MOSFETs are capable of delivering low ON resistance with high-speed switching performance, contributing to greater miniaturization and lower power consumption in a variety of applications, including automotive traction inverters and switching power supplies. Bare chip samples have been made available from June 2020, with discrete packages to be offered in the future.

ROHM is committed to continuing to expand its SiC power device lineup while combining modularization technologies with peripheral devices such as control ICs designed to maximize performance in the order to contribute to technical innovation in next-generation vehicles. At the same time, ROHM will provide solutions that resolve customer issues – including web-based simulation tools that reduce application development man-hours and help prevent evaluation problems.

Key Features

1) Improved trench structure delivers the industry’s lowest ON resistance

Image courtesy of ROHM

In 2015, ROHM began mass production of the industry-first trench-type SiC MOSFETs utilizing an original structure. Now, ROHM has successfully reduced ON resistance by 40% compared to conventional products without sacrificing short-circuit withstand time by further improving its original double trench structure.

2) Achieves lower switching loss by significantly reducing parasitic capacitance

Image courtesy of ROHM

Generally, lower ON resistances and larger currents tend to increase the various parasitic capacitances in MOSFETs, which can inhibit the inherent high-speed switching characteristics of SiC.

However, ROHM was able to achieve 50% lower switching loss over conventional products by significantly reducing the gate-drain capacitance (Cgd).

About ROHM

Founded in 1958, ROHM provides LSI and discrete semiconductors characterized by outstanding quality and reliability for a broad range of markets, including automotive, industrial and consumer market via its global development and sales network. In the analog power field, ROHM proposes the suitable solution for each application with power devices such as SiC, driver ICs to maximize their performance, and peripheral components such as transistors, diodes and resistors.